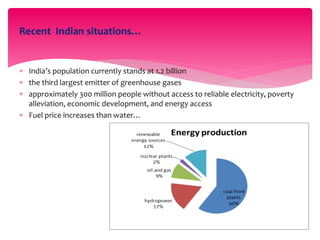

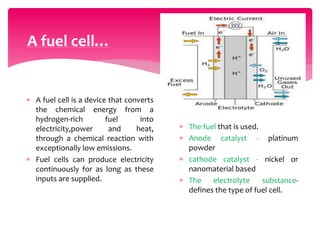

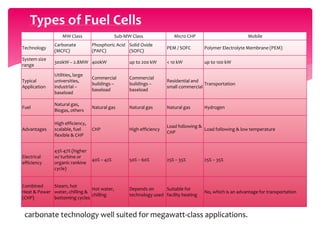

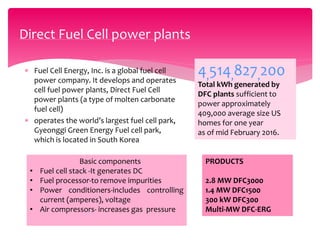

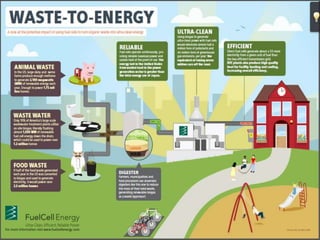

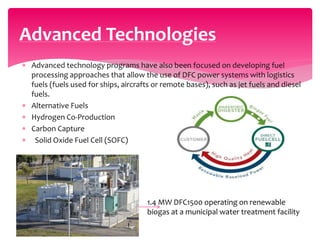

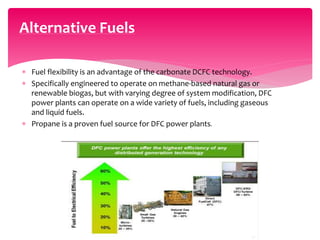

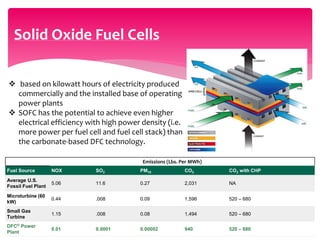

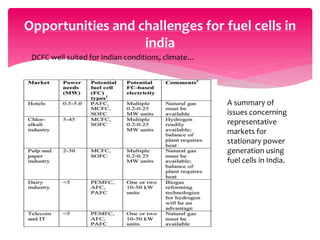

The document discusses India's climate pledge made at the Paris Climate Summit in 2015, including targets to reduce greenhouse gas emissions intensity by 33-35% by 2030 and increase renewable energy capacity. It also summarizes the types, advantages, and applications of direct carbon fuel cells, which are well-suited for Indian conditions due to their ability to operate on various carbon-based fuels including coal and biomass. DCFCs produce very low emissions and could provide a cost-effective solution for power generation while utilizing waste biomass in India.