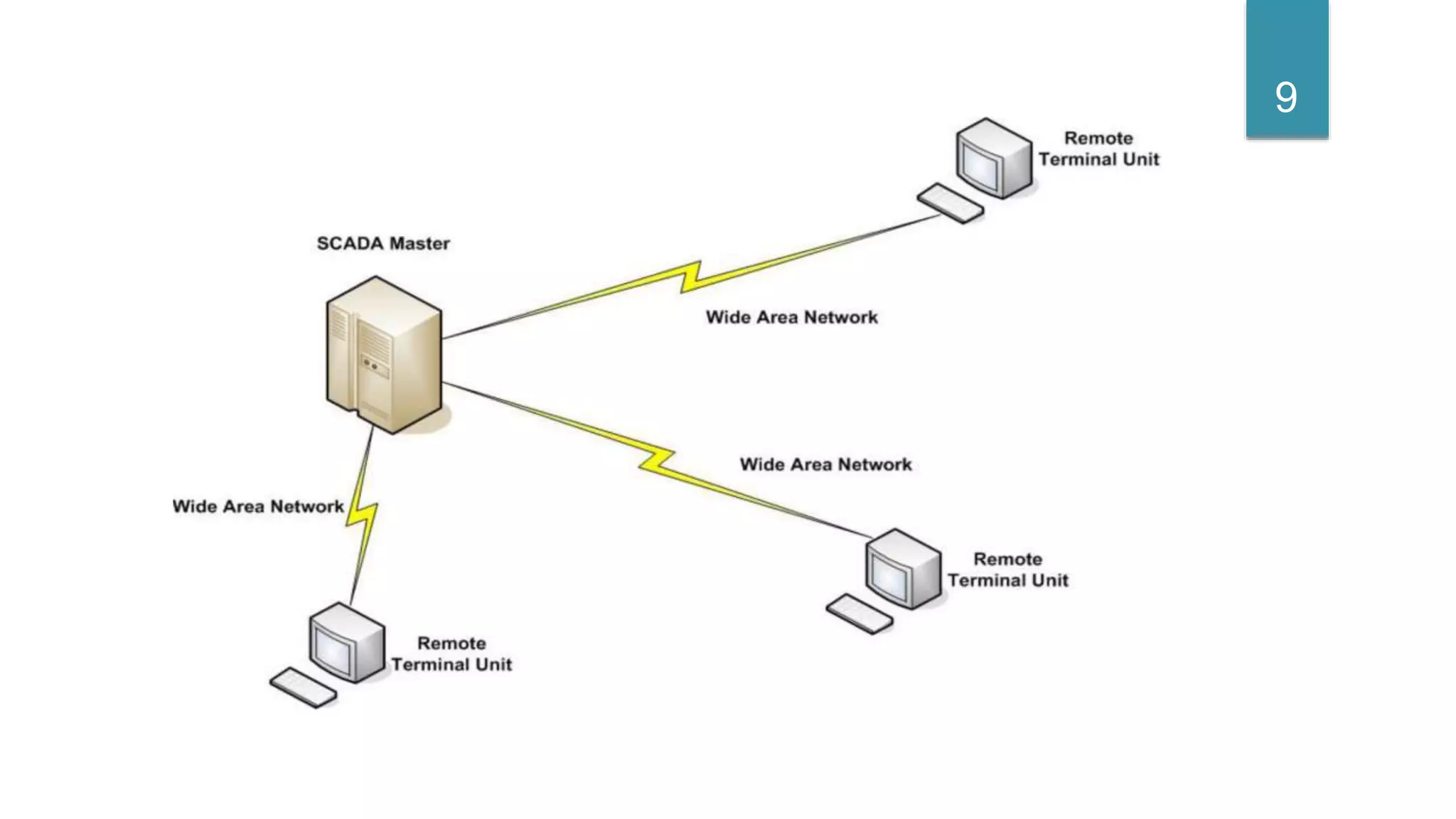

SCADA systems are used to monitor and control industrial processes remotely. They acquire data from sensors in the field through programmable logic controllers (PLCs) or remote terminal units (RTUs), transmit the data to centralized human-machine interfaces (HMIs) over telecommunication networks, and allow operators to send control commands back to the field devices. SCADA systems have evolved from monolithic first-generation systems with standalone computers to distributed second-generation and networked third-generation systems that use open standards and can connect over wide area networks. They provide features like dynamic representation of process data, database connectivity, device connectivity, alarms, trends, scripting, security, recipe management, and networking capabilities.