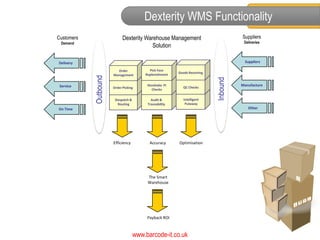

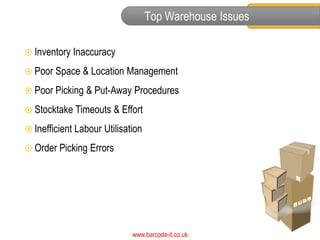

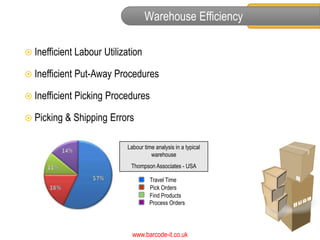

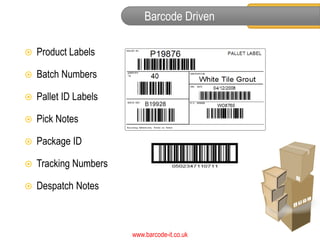

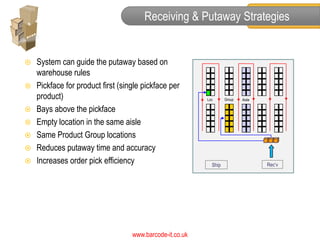

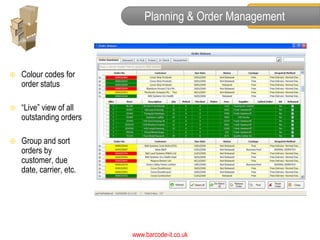

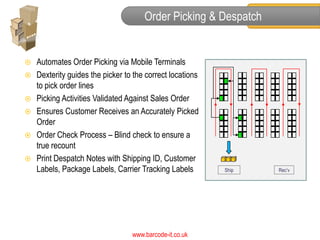

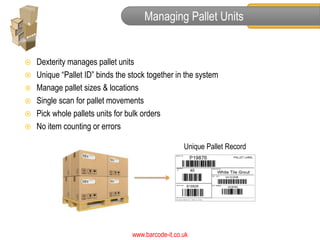

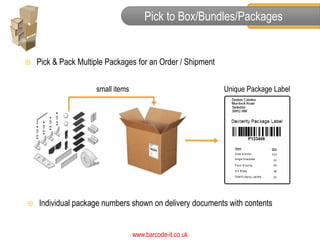

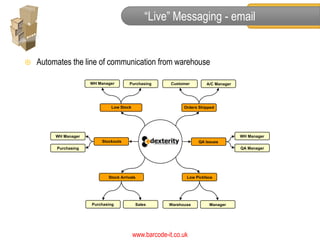

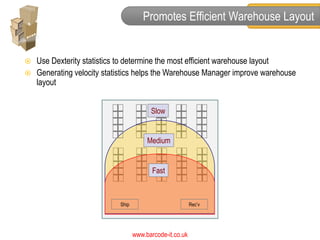

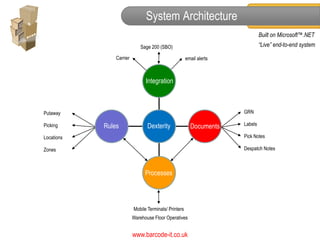

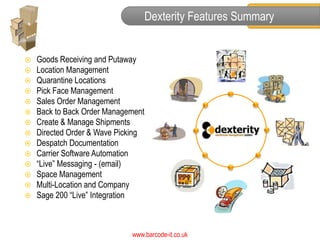

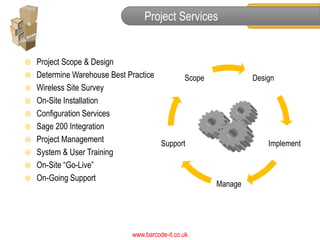

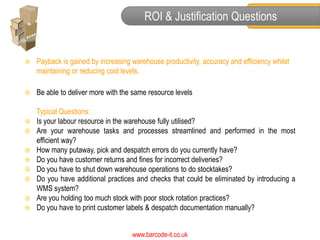

Dexterity Warehouse Management, established in 1989, offers a comprehensive WMS integrated with Sage 200, facilitating efficient inventory management and order processing. Key functionalities include inventory control, automated order picking, and live messaging, all aimed at improving warehouse operations and reducing errors. The system supports various technologies, from mobile terminals to barcode scanning, ensuring flexibility and compatibility within diverse warehouse environments.