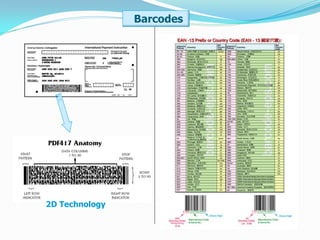

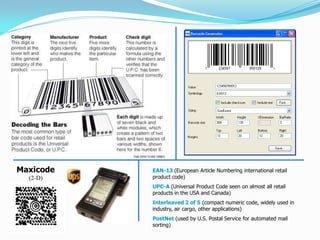

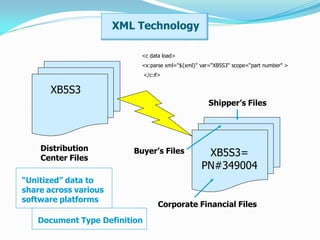

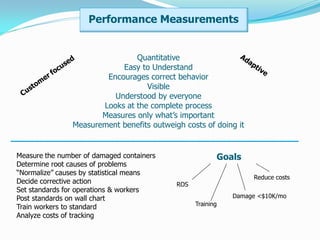

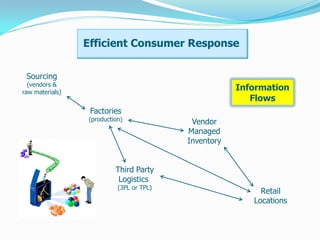

Kraft must connect its production, sales, and logistics internally through an intranet and externally through the internet with suppliers, third party logistics providers, and customers to efficiently manage information and product flows. Various technologies are used for this, including barcodes, RFID, XML, and EDI to track products and share data across systems. Key performance metrics focus on reducing costs, damage, and improving training to meet goals and standards for efficient operations.