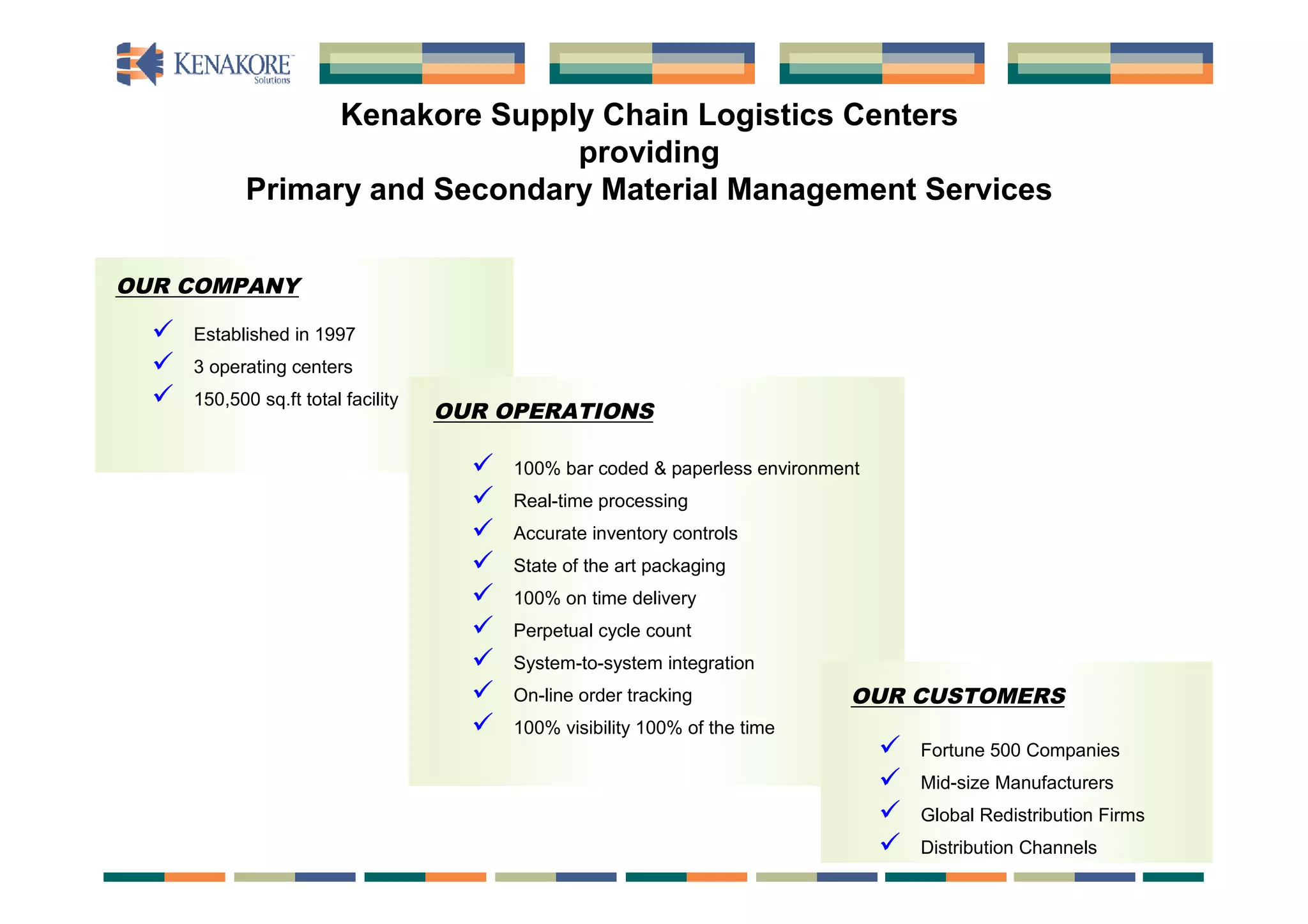

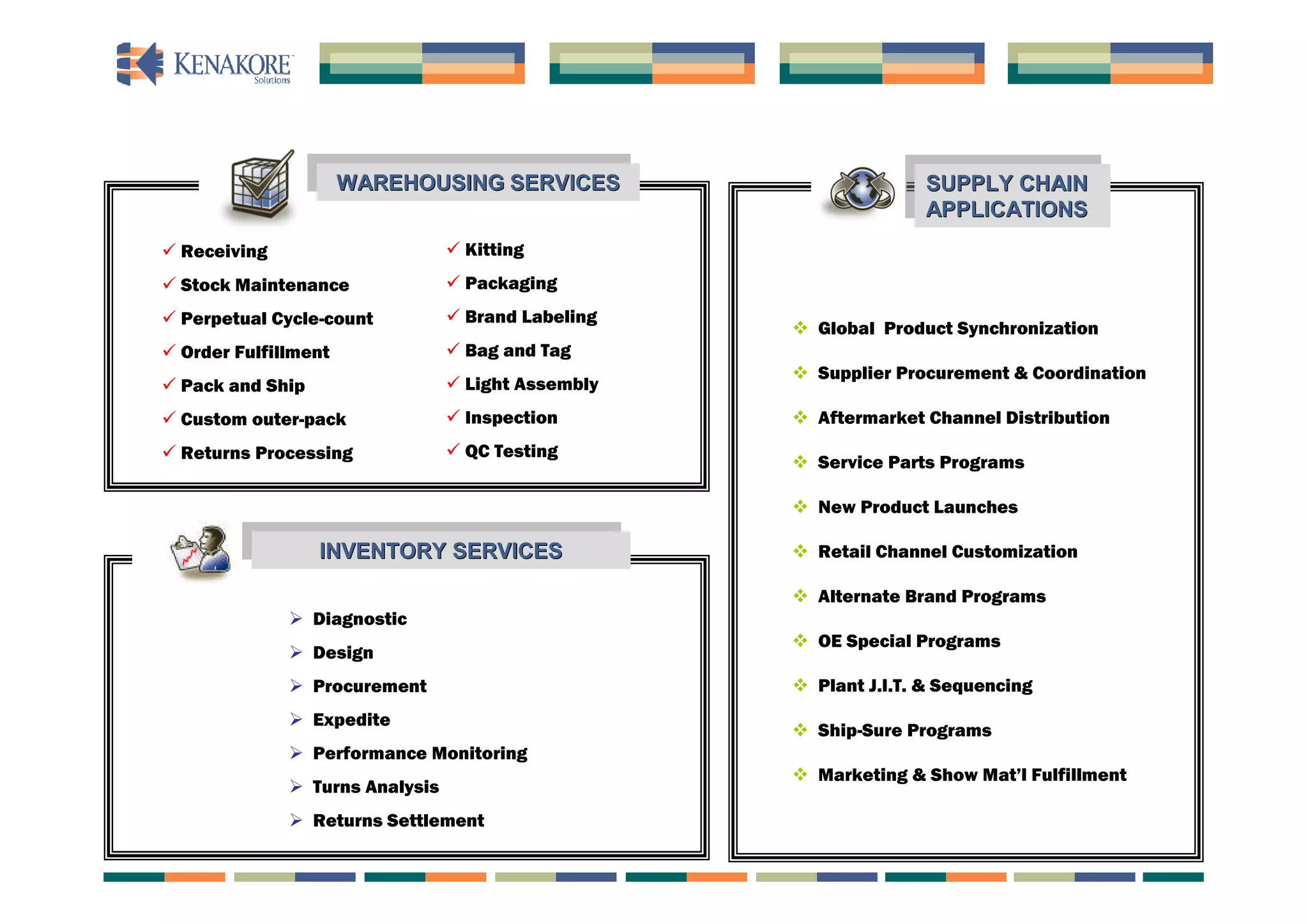

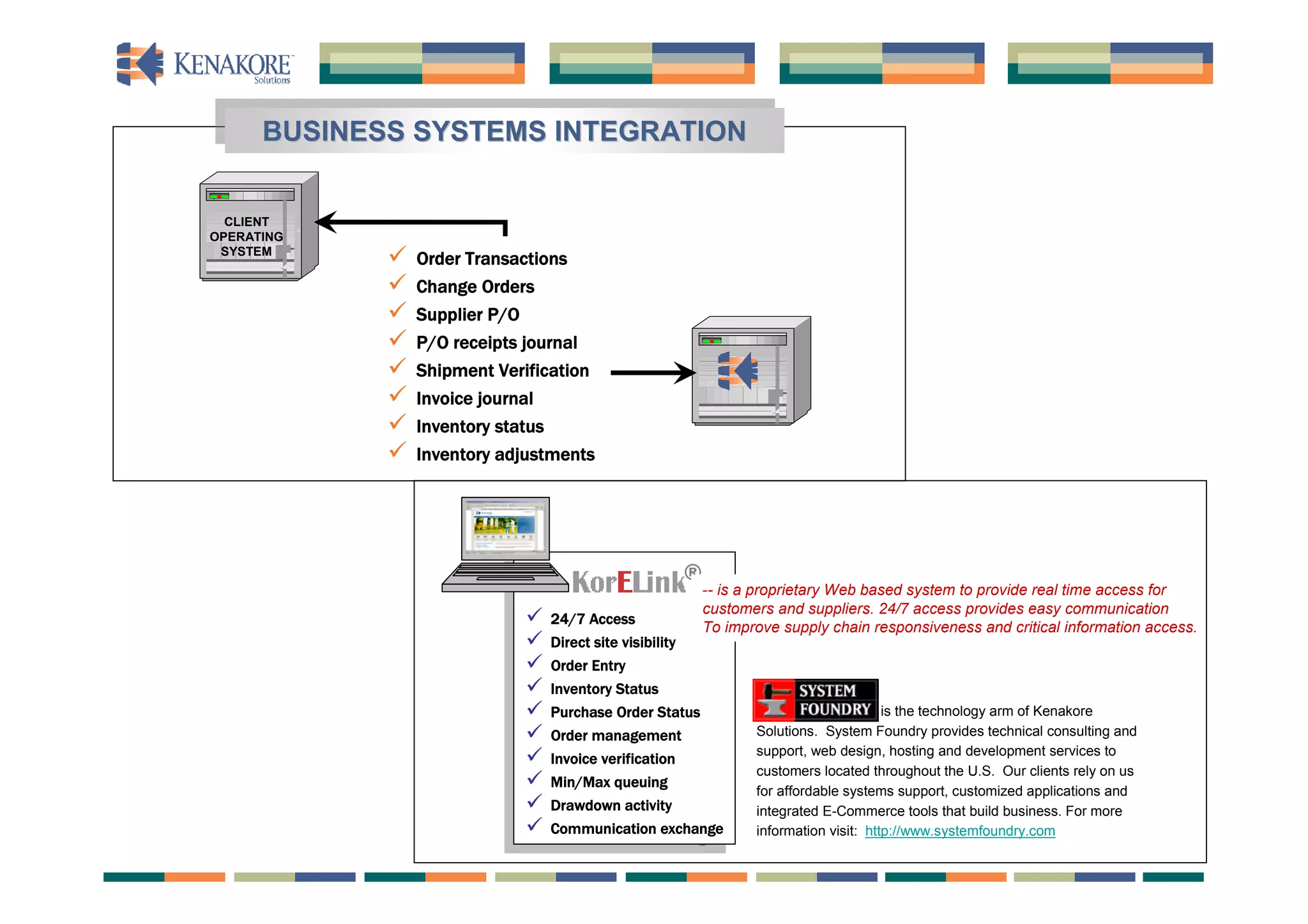

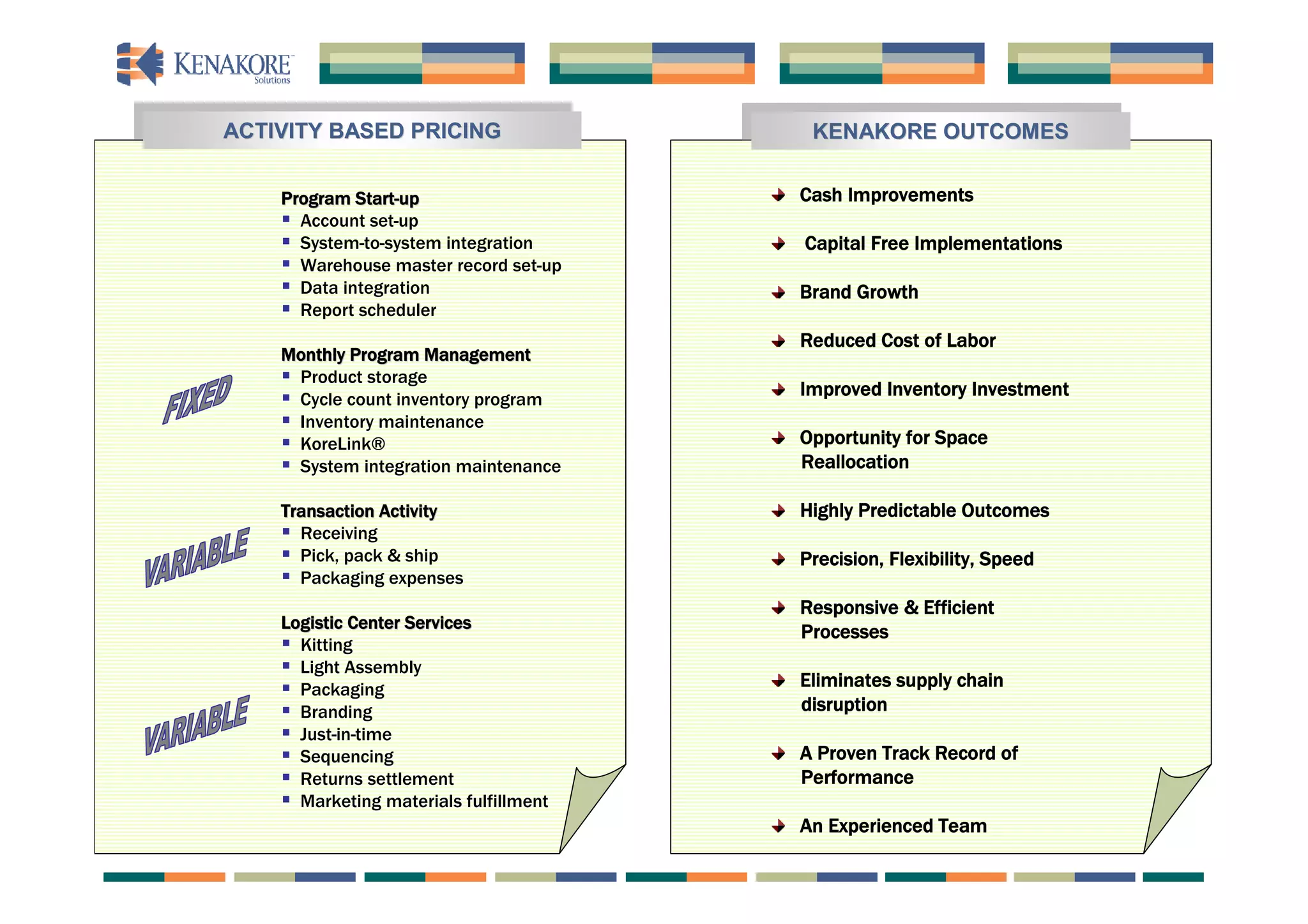

Kenakore Supply Chain Logistics Centers provides primary and secondary material management services through its three operating centers totaling 150,500 square feet. It offers a 100% paperless and barcoded environment with real-time processing, accurate inventory controls, and on-time delivery. Kenakore's customers include Fortune 500 companies, mid-size manufacturers, and global redistribution firms.