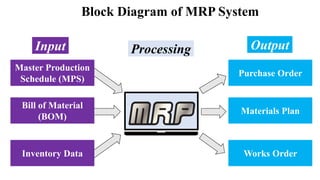

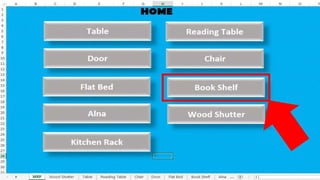

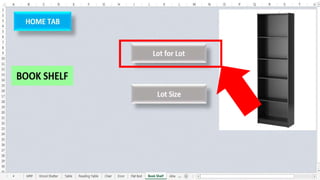

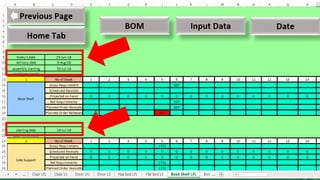

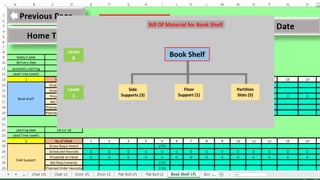

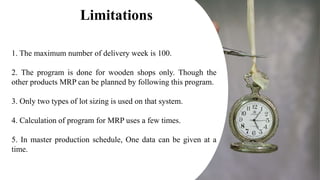

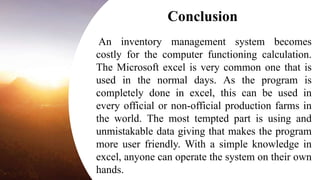

The document outlines the development of a materials requirements planning (MRP) system using Microsoft Excel, supervised by an assistant professor at Khulna University of Engineering & Technology. It aims to ensure material availability, optimize service levels, and minimize costs, utilizing techniques such as lot-for-lot and lot-size ordering. The system is user-friendly, designed for wooden shops, and can be operated with basic Excel knowledge, although it has limitations related to cost and complexity in inventory management.