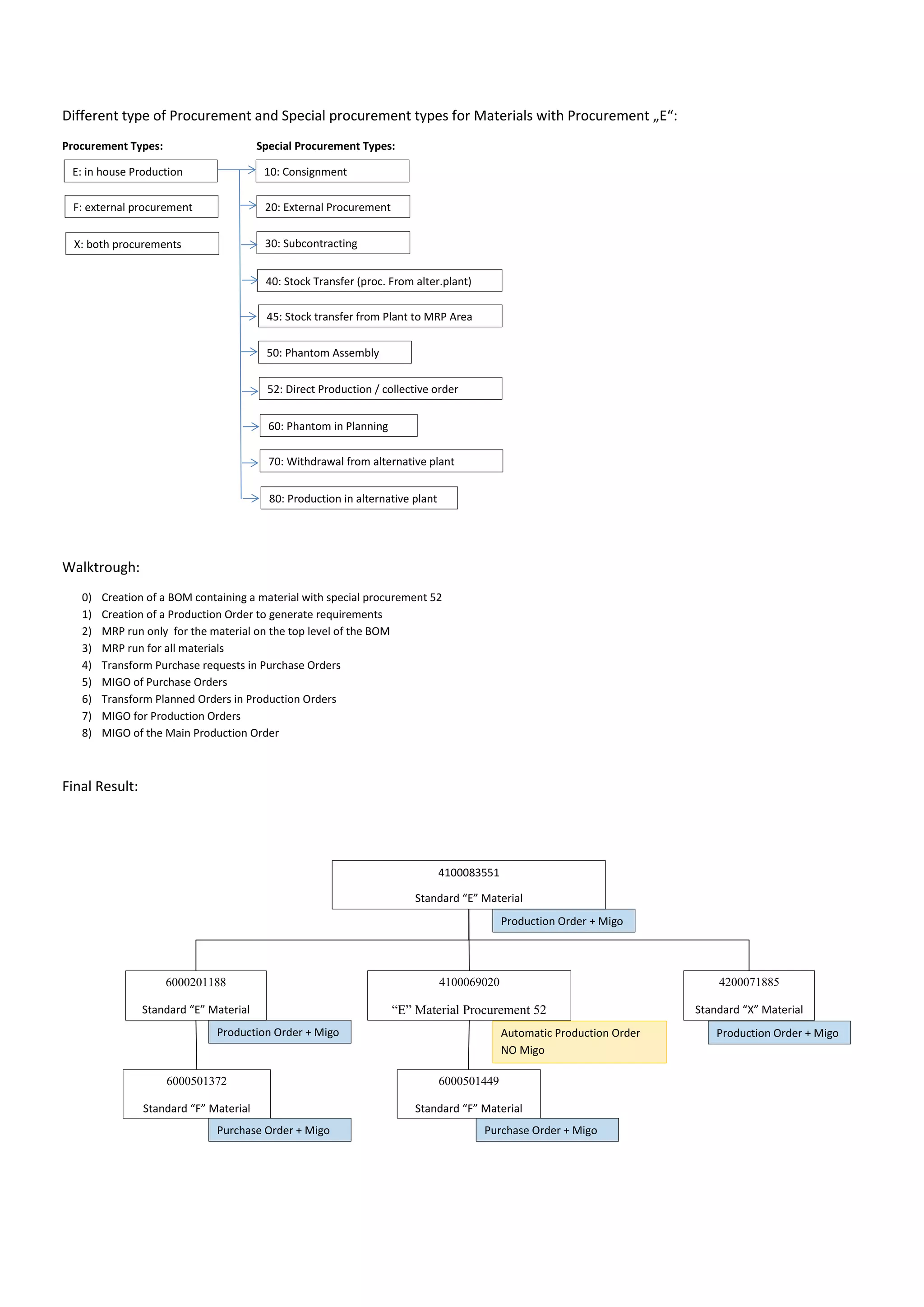

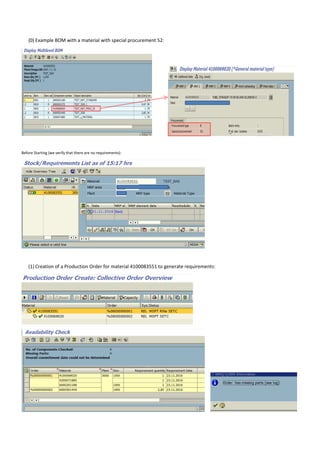

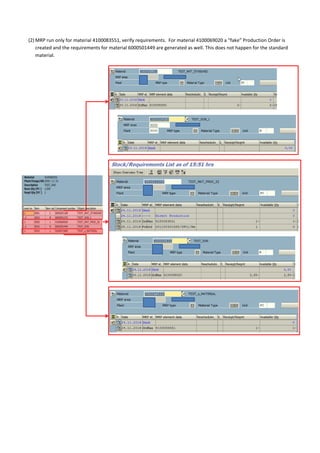

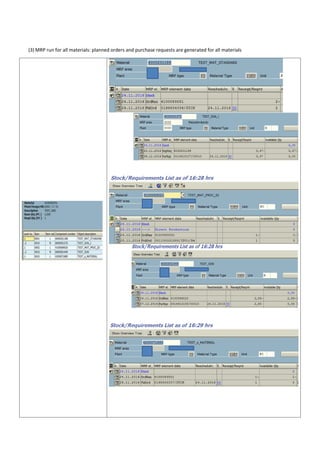

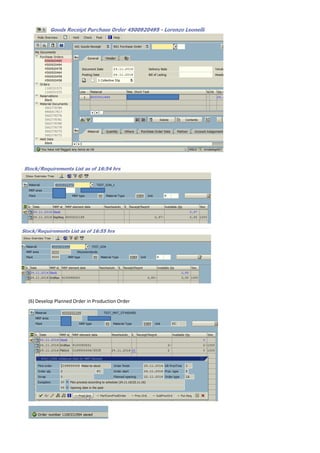

The document describes different types of procurement and special procurement types for materials in procurement "E". It provides an example process for a bill of materials containing a material with special procurement type 52. The process involves: 1) Creating a production order to generate requirements for the material; 2) Running MRP only for that material to create a "fake" production order; 3) Running full MRP to generate planned orders and purchase requests for all materials.