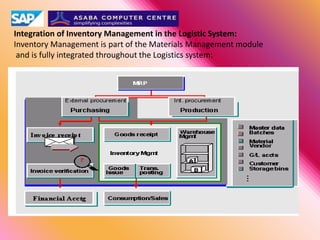

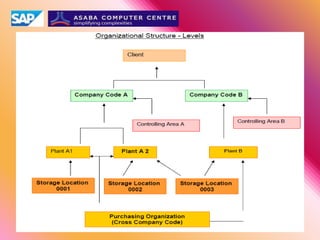

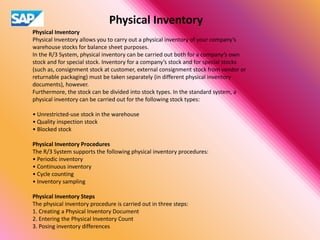

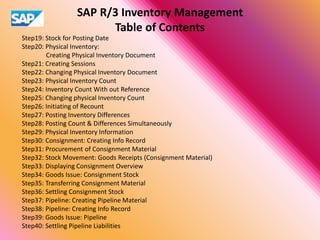

Inventory management in SAP tracks materials from procurement to usage or sale. It integrates with other logistics modules to share master and transactional data. Goods movements like receipts and issues are recorded in real-time to update stock quantities and values. Physical inventory involves creating documents, entering counts, and posting differences between system stock and physical counts. The document provides an overview of SAP's inventory management module and its key capabilities like goods movements, reservations, transfers, physical inventory, and special stocks for consignment and pipelines.