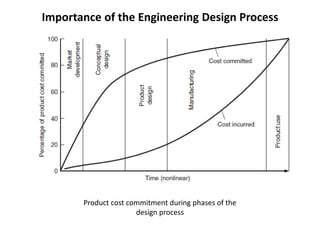

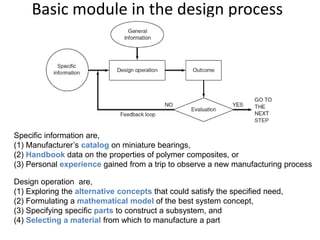

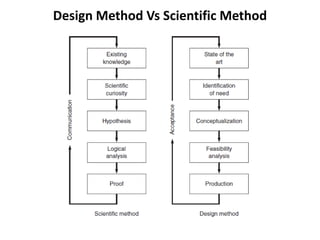

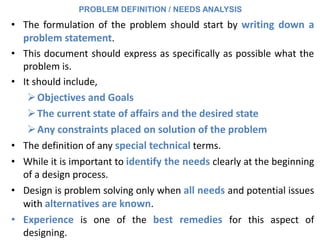

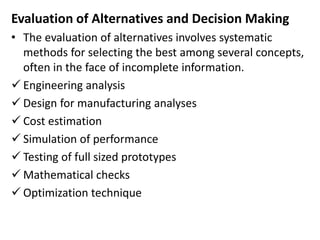

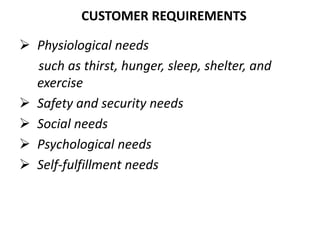

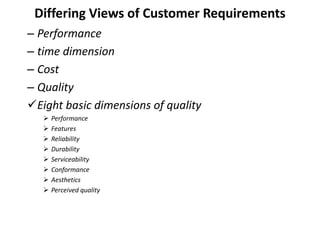

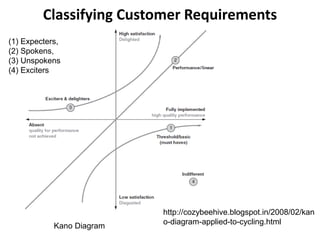

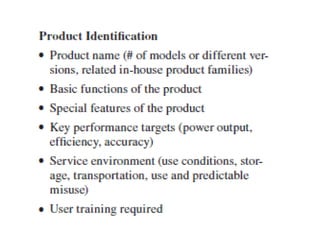

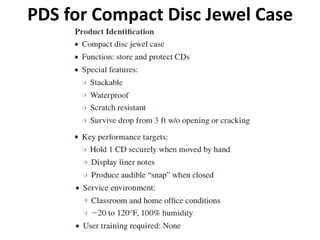

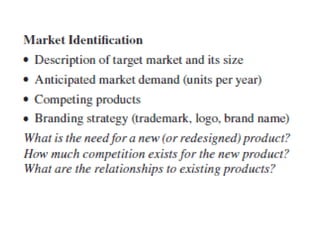

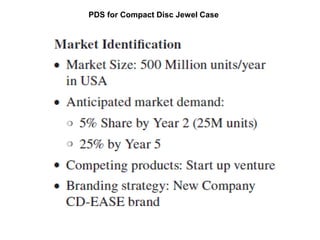

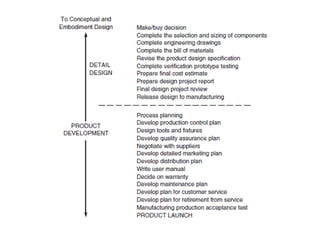

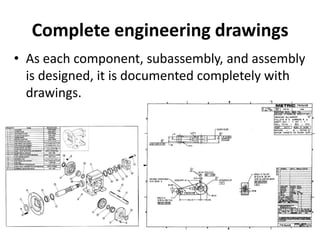

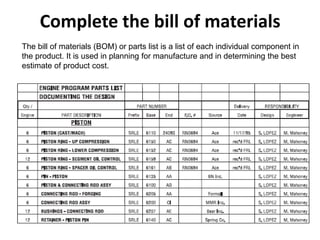

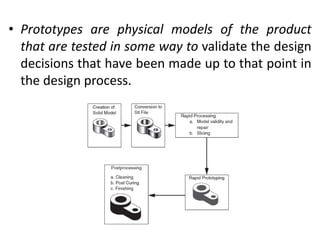

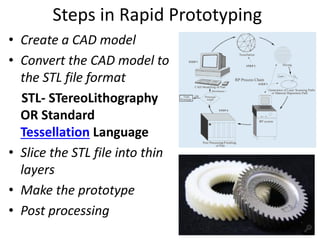

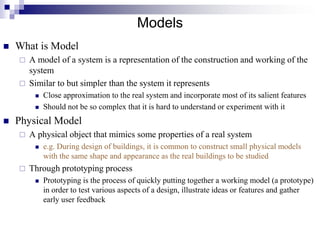

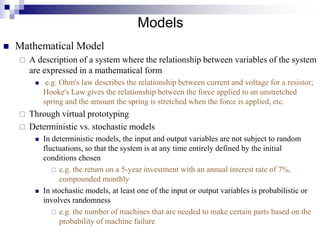

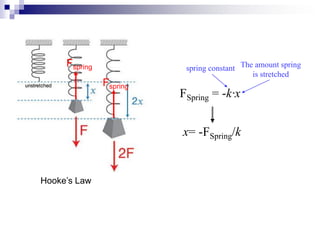

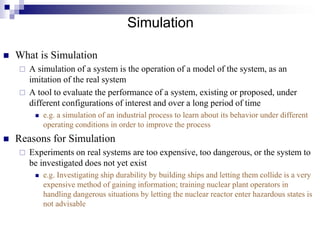

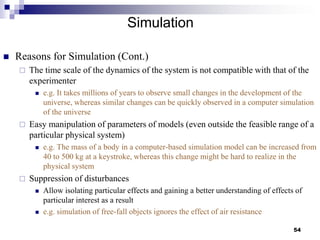

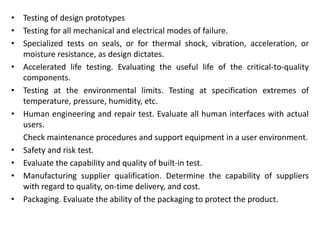

The document discusses the basic design process which includes need identification, defining the problem, gathering customer requirements, generating alternative solutions, analysis and selection, detail design, prototyping, modeling, simulation, and testing. It covers topics such as developing a problem statement, conducting research to gather information, generating and evaluating design concepts, designing the product details through drawings and specifications, building prototypes for testing, and releasing the final design for production. The overall process aims to design a product that meets customer needs and can be successfully manufactured.