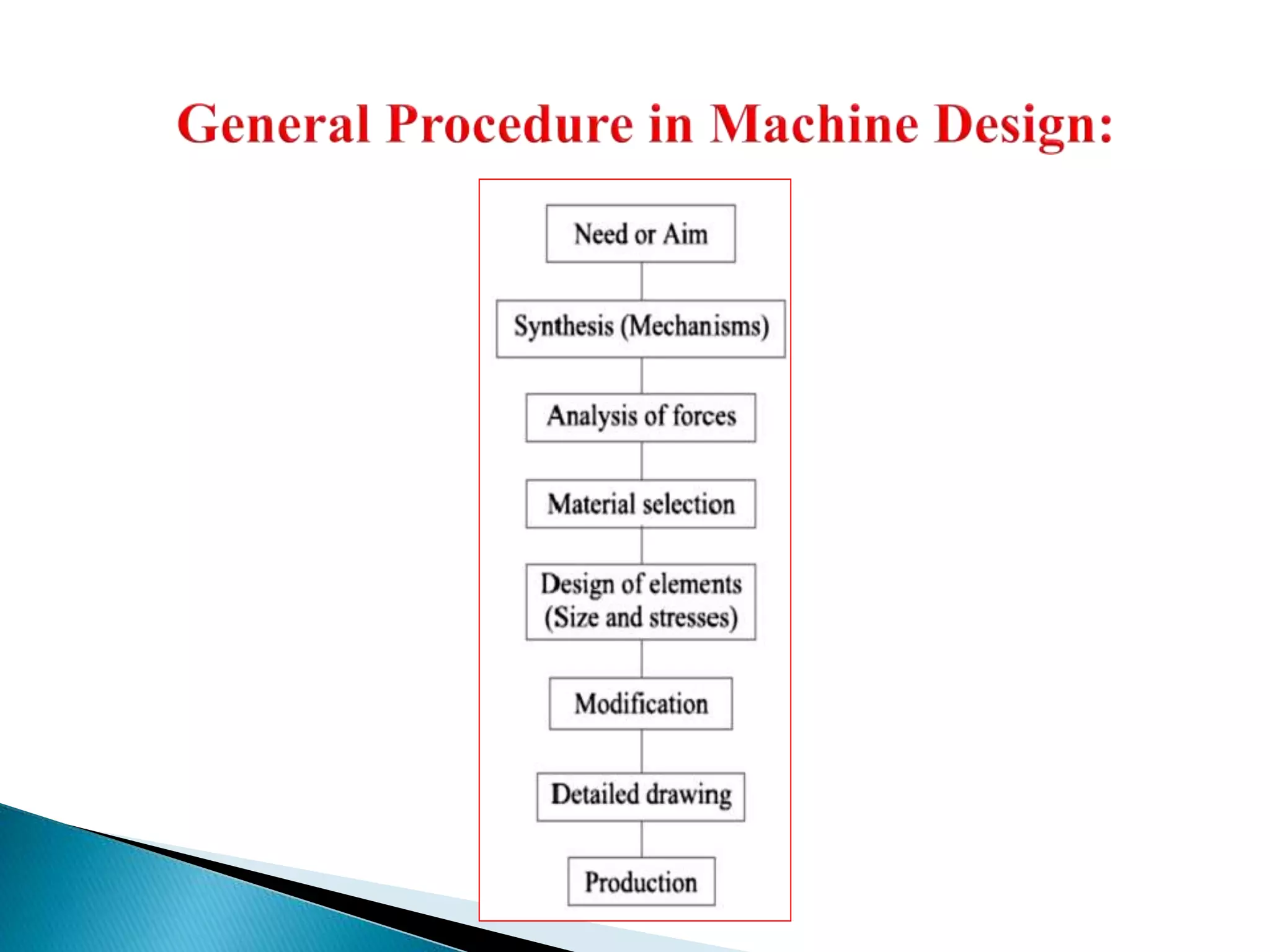

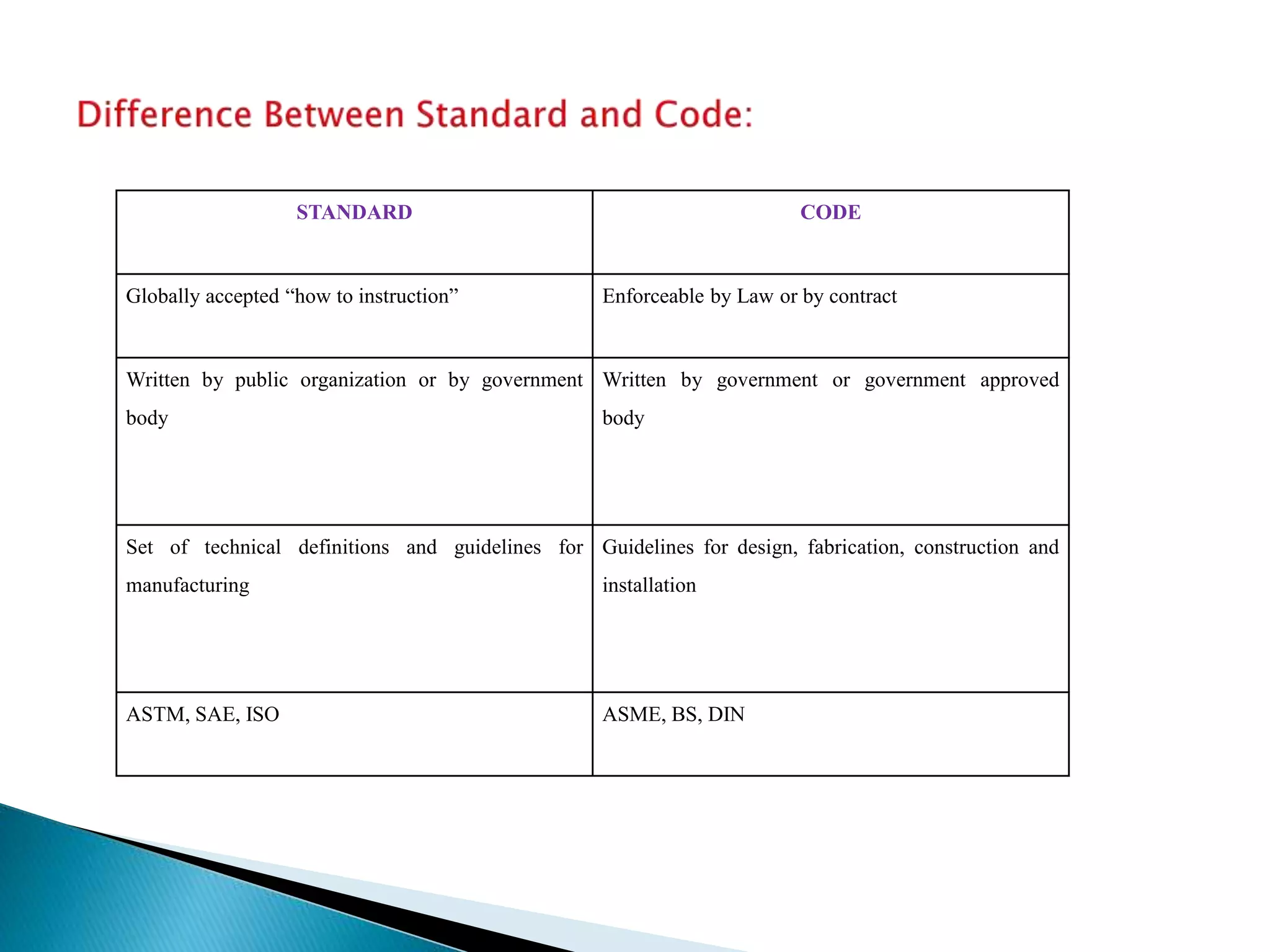

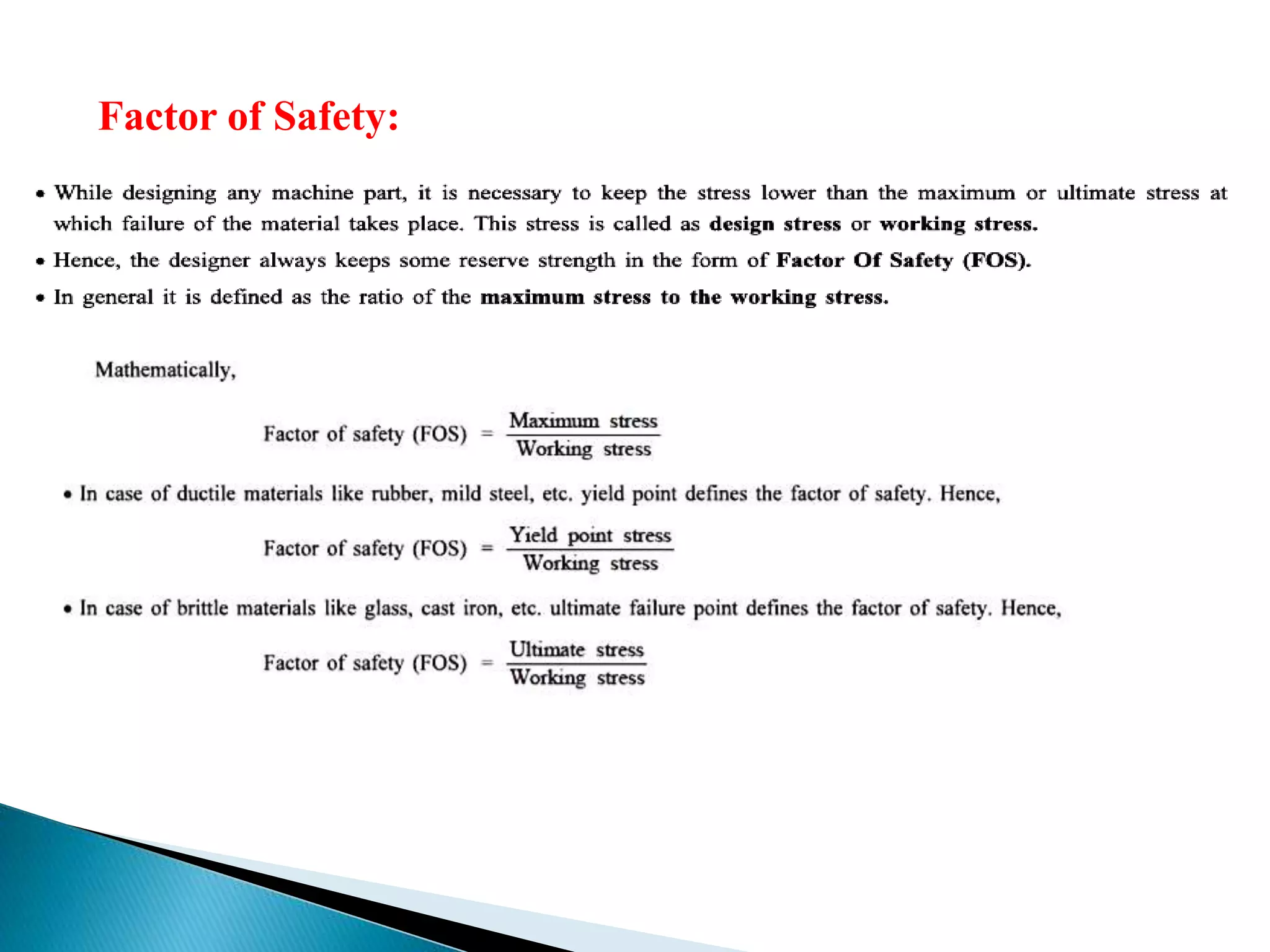

The document covers the design of simple machine elements, emphasizing factors such as strength, rigidity, and safety. It discusses various design methodologies and the importance of standards in machine design to ensure quality, efficiency, and interoperability of components. Additionally, it details the role of codes in regulating safety and quality in manufacturing, along with the concepts of factor of safety and service factor in machine operations.