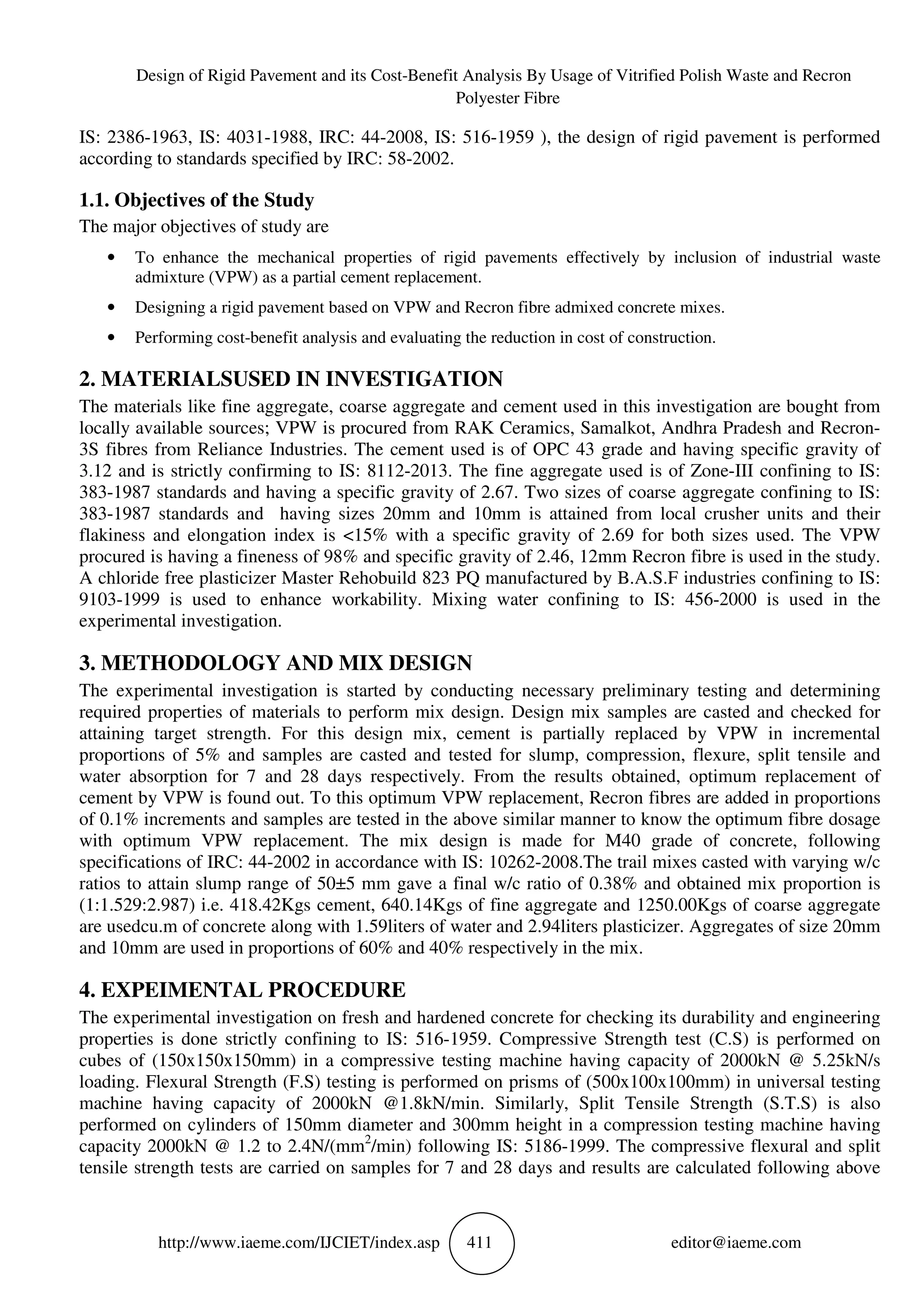

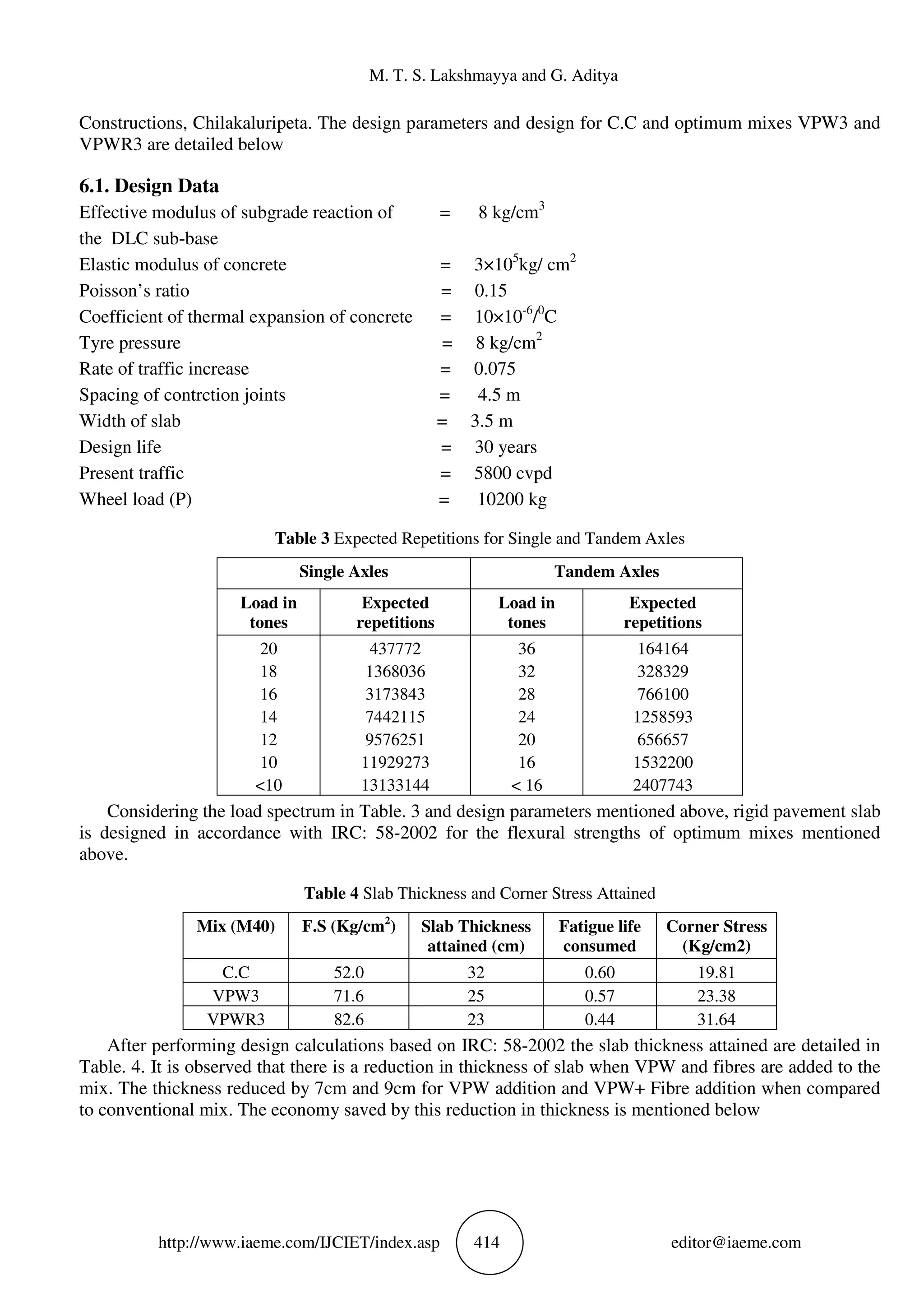

The document discusses the design and cost-benefit analysis of rigid pavements using vitrified polish waste (VPW) and Recron polyester fiber as a partial cement replacement. It highlights the advantages of rigid pavements such as lower maintenance costs and longer lifespan compared to flexible pavements, which dominate India's road systems. The study concludes with findings on mechanical properties and suggests optimal combinations for improving concrete strength and reducing construction costs.

![M. T. S. Lakshmayya and G. Aditya

http://www.iaeme.com/IJCIET/index.asp 410 editor@iaeme.com

1. INTRODUCTION

After understanding the importance and necessity of rigid pavement construction many researches and

studies are conducted in this aspect. The studies mainly focused on improvement of mechanical and

durability properties of concrete by usage of various additives, admixtures and fibres to concrete mix.

These admixtures are used as partial or full replacement of cement along or without fibres. The fibres used

are also available in different types like steel, glass etc. Studies are also conducted on them individually as

well as compositely.Luiz Renato, Steiner Adriano et.al [2001] studied, the properties of sludge obtained

from polishing of ceramic tiles. X-ray diffraction, X-ray fluorescence, laser diffraction and several other

tests were conducted to study physical and chemical properties of this sludge. Also, recommended its

usage as Supplementary Cementious Material (SCM) in various engineering constructions. Jay Patel, B.K.

Shahet.al [2014] in his literature analysis about ceramic waste inclusion in concrete making concluded that,

ceramic products have good pozzolanic activity because of their manufacturing temperature and its usage

is good for economy and environment. He also concluded that, cost of construction can be reduced by 20-

30% for higher grades of concrete by its usage.

Electricwala Fatima, Ankit Jhamb, Rakesh Kumar et al [2013] have investigated on M35 grade of

concrete by replacing up to 30% of cement with ceramic dust and observed an increment in compressive

strength, flexural strength. The results showed an increase in compressive strength by 3.9% to 5.6% by

replacing 20% cement content with ceramic dust. Ponnapati Manogna, M. Sri Lakshmi [2015]

investigated on partial replacement of cement by tile waste in M30 grade of concrete in increments of 10%

up to 50%.Compressive, tensile and flexural strength tests were conducted for 7, 28 and 56 days

respectively and suggested that a replacement up to 30% can be made without compromising on design

strength. However, optimum results for compression,tension and flexure strength were attained at 10%

replacement. Abhinav. S. Pawar, K.R. Dhabekar [2014] investigated on addition of waste material (GGBS)

and steel fibresin M40 grade concrete for rigid pavement and compared with normal concrete of M40

grade.After testing it was found that, 30% GGBS is the optimum replacement for M40 grade of concrete

but, flexural strength decreased by increasing percentage of GGBS, so as to increase flexural strength, steel

fibres of two different aspect ratios (7560 & 7530) were used. Steel fibres were added in concrete by 1% of

total weight of concrete with different proportions.

Nandish S.C, Ajith B.T et.al [2015] studied about strength enhancement of conventional concrete with

addition of Coconut fibres and polypropylene fibres. The coconut fibres of various proportions like 1%,

1.5%, 2%, 2.5% and polypropylene fibres of proportions of 0.4% by volume of concrete were used in the

M40 grade concrete mix tests to determine the mechanical properties of concrete up to 7, 28, 56 and 90

days. Use of fibres tends to enhance the flexural strength of the mix. Fibre mixed concrete has higher value

than that of the control mix. For 2.0%CF and 0.4%PF of fiber, flexural strength found to be 14% higher

than that of control mix concrete. Mehul. J. Patel, S. M. Kulkarni [2013] studied effects of poly propylene

fibres on M40 grade of concrete by adding in proportions of 0.5%, 1%, and 1.5% and investigated for

compressive, flexural and split tensile strengths and reported an increase in above parameters when

compared to conventional concrete.

Vipul. D. Prajapathi, Nilay Joshi et.al [2013] experimented on usage of fine aggregate replaced by used

foundry sand in proportions of 0%, 10%, 30% and 50% for M20 grade of concrete and studied their

mechanical properties. He concluded that, maximum compressive and flexural strengths are achieved at

50% replacement of natural fine aggregate with used foundry sand and designed a pavement for

3000CVPD flow. As a part of such studies, usage of Vitrified Polish Waste (VPW) along with recron

polyester fibre is studied in this experimental investigation. Ceramic industry is extensively growing with

the infrastructural needs of the present world and waste generated is also increasing rapidly there by

incorporating these wastes in pavement construction will also help environmentally. A good study on

Indian standard codes for laboratory sampling, and testing of concrete and materials used is also done

before proceeding into testing phase, which includes the following codes (IS: 10262-2009 , IS: 456-2000 ,](https://image.slidesharecdn.com/ijciet0801046-170304080418/75/DESIGN-OF-RIGID-PAVEMENT-AND-ITS-COST-BENEFIT-ANALYSIS-BY-USAGE-OF-VITRIFIED-POLISH-WASTE-AND-RECRON-POLYESTER-FIBRE-2-2048.jpg)

![M. T. S. Lakshmayya and G. Aditya

http://www.iaeme.com/IJCIET/index.asp 416 editor@iaeme.com

• The compressive and flexural strengths of optimum VPW mix with 3% R.P.F increased by 10.9% and 16%

for 28 days when compared to VPW optimum mix without fibres.

• The workability of the mix decreased gradually because of VPW addition and when further fibre is added to

mix, workability decreased even more

• There is a nominal reduction in compressive strength in HCl resistance test which is in permissible limits

• The water absorption increased considerably with increase in VPW addition, when fibres are added to

optimum VPW this increased further.

• The thickness of pavement attained for mixes CC, VPW3, VPWR3 are 32, 25 and 23 cm respectively

• Cost of construction decreased when compared to design mix for VPW3 and VPWR3

• The environmental disposal problem of industrial wastes can be tackled. There by leading to sustainable and

eco- friendly pavement construction.

9. ACKNOWLEDGEMENTS

I humbly express my profound gratitude to my guide M.T.S. Lakshmayya for his guidance and my parents

for their support during the course of study. I would also like to thank the H.O.D, faculty members and lab

technicians, department of civil engineering, GMRIT for their cooperation

REFERENCES

[1] Luiz Renato, Steiner Adriano et.al,”Effectiveness of ceramic tile polishing residues as supplementary

cementitious materials for cement mortars", The Journal Of Sustainable Materials And

Technologies,vol.4,pp-30-35,April 2014.

[2] Jay Patel, B.K. Shah, P.J. Patel, “Ceramic Powder in Concrete by Partial Replacement of Cement- A

Literature Analysis”, Journal of International Academic Research for Multi-Disciplinary, Vol-2, Isuue-3,

April- 2014, ISSN-2320-5083

[3] Fatima, Electricwala, Ankit Jhamb, and Rakesh Kumar. "Ceramic Dust as Construction Material in

Rigid Pavement." American Journal of Civil Engineering and Architecture 1.5 (2013): 112-116.

[4] Ponnapati Manogna, M. Sri Lakshmi, “Tile Powder as Partial Replacement of Cement in Concrete”,

International Research Journal of Engineering and Technology, Vol-2, Issue-4, July-2015, e- ISSN-

2395-0056.

[5] Abhinav.S.Pawar,K.R.Dabhekar,”Study of Concrete based Pavement by using Fibres and Cementing

Waste Materials” International Journal of Research in Engineering and Technology,Vol-3,issue-5,May-

2014.

[6] Nandish S.C,Ajith B.T et.al,”Impact of Coconut Fibre and Polypropylene Fibre (Recron 3s) on

Concrete Mix Including Admixture” International Journal Of Engineering Research And Technology,

ISSN: 2278-018,vol.4,issue 6,June 2015

[7] Mehul. J. Patel, S. M. Kulkarni, “Effect of Polypropylene Fibre on High Strength Concrete”, Journal of

Information, Knowledge and Research in Civil Engineering”, Vol-2, Issue -2, October- 2013, ISSN-

0975-6744.

[8] Vipul. D. Prajapathi, Nilay Joshi, Jayesh Kumar Pitroda, “Techno- Economical Study of Rigid

Pavements by Usage of Used Foundry Sand”, International Journal of Engineering Trends and

Technology, Vol-4, Issue-5, May-2013, ISSN-2321-5381

[9] VenkataSairam Kumar, Dr.B.Panduranga Rao, Krishna Sai M.L.N,” Experimental study on partial

replacement of cement with quarry dust, International Journal of Advanced Engineering Research and

Studies E-ISSN: 2249–8974. IS: 2720 (Part - 16)-1979, "Laboratory determination of CBR". June 2013.

[10] R. Srinivasan, K. Sathiya, “Experimental Study of Bagasse ash in Concrete”, international Journal for

Service Learning in Engineering, Vol. 5, No. 2, pp. 60-66, Fall 2010, ISSN 1555-9033.](https://image.slidesharecdn.com/ijciet0801046-170304080418/75/DESIGN-OF-RIGID-PAVEMENT-AND-ITS-COST-BENEFIT-ANALYSIS-BY-USAGE-OF-VITRIFIED-POLISH-WASTE-AND-RECRON-POLYESTER-FIBRE-8-2048.jpg)

![Design of Rigid Pavement and its Cost-Benefit Analysis By Usage of Vitrified Polish Waste and Recron

Polyester Fibre

http://www.iaeme.com/IJCIET/index.asp 417 editor@iaeme.com

[11] Dhillon. Ramandeep, Sharma. Shruti et.al, “Effect steel and polypropylene fibres on fly ash concrete”,

International Journal of Research in Advent Technology, Vol. 2, No. 3, March 2014, E-ISSN: 2321-

9637

[12] Bibha Kumari and Vikas Srivastava, Effect of Waste Plastic and Fly Ash on Mechanical Properties of

Rigid Pavement. International Journal of Civil Engineering and Technology (IJCIET), 7(5), 2016,

pp.247–256.

[13] Shaik. Allimran Tippu, Vr. Prasanth Kumar, “A study on effect of silica fume on mechanical properties

of light weight coconut shell concrete”, International Journal of Research in Engineering and

Technology, Vol-4, Issue-4, April 2015, E-ISSN: 2319-1163

[14] IS: 10262-2009, “Recommended guidelines for concrete mix design, Bureau of Indian standards”, New

Delhi, India.

[15] IS 456 -2000, “Code of Practice for Plain and Reinforced Concrete”, Bureau of Indian Standards, New

Delhi.

[16] IS: 2386-1963, “Methods of testing aggregate for concrete”.

[17] IS: 4031-1988, “Code for physical tests on O.P.C”.

[18] IRC: 44-2008, “Recommended guidelines for mix design of Cement Concrete Pavements”

[19] IS: 516-1959, “Indian standard methods of tests for strength of concrete, Bureau of Indian Standards”,

New Delhi, India

[20] IRC: 58-2002, “Guide lines for the design of plain jointed Rigid Pavements for the Highways”.

[21] IS: 8112-2013, “Indian standard specifications for OPC 43 grade cement”.

[22] IS: 383-1987, “Indian standard specifications for coarse and fine aggregate from natural sources for

concrete”.

[23] IS: 9103-1999, “ Indian standard specifications for concrete admixtures”

[24] Messi Alfred François, Mamba Mpele, Tchoumi Dany Franky, Koumbe Mbock and Okpwe Mbarga

Richard, Multiple Correlations between Physical Properties of Lateric Soils for Pavement Design.

International Journal of Civil Engineering and Technology (IJCIET), 7(5), 2016, pp.485 – 499](https://image.slidesharecdn.com/ijciet0801046-170304080418/75/DESIGN-OF-RIGID-PAVEMENT-AND-ITS-COST-BENEFIT-ANALYSIS-BY-USAGE-OF-VITRIFIED-POLISH-WASTE-AND-RECRON-POLYESTER-FIBRE-9-2048.jpg)