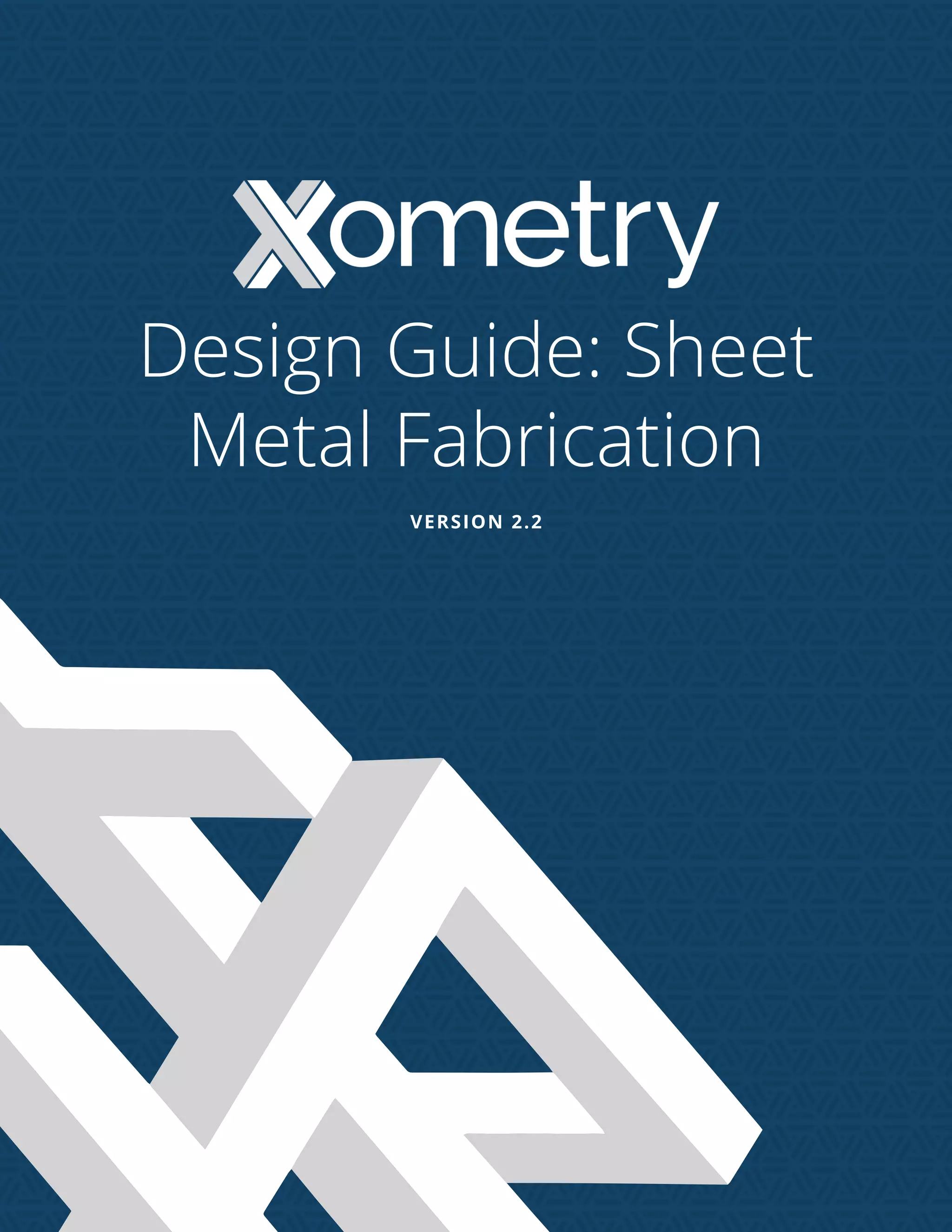

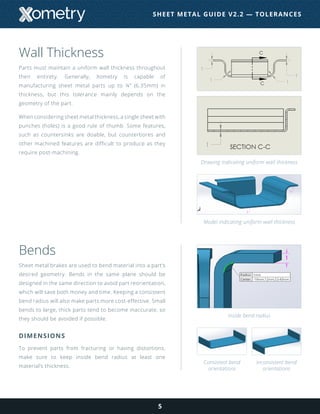

This document provides guidelines and tolerances for sheet metal fabrication. It outlines dimensional tolerances for various features like wall thickness, bends, holes and other elements. It also provides clearance distances between features to avoid defects. The document aims to help designers create parts that can be accurately manufactured within the tolerances of sheet metal processing. It highlights resources at Xometry for quoting, support, file types accepted and materials offered for sheet metal fabrication.