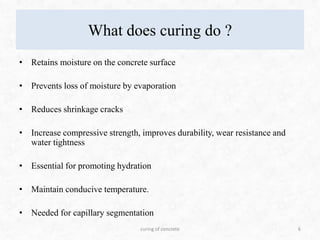

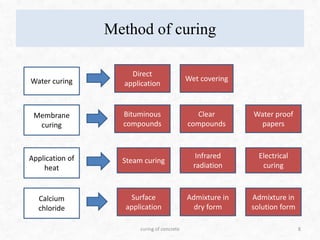

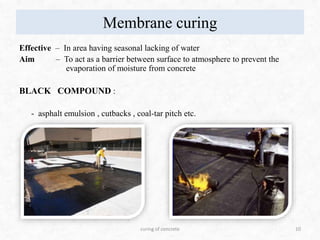

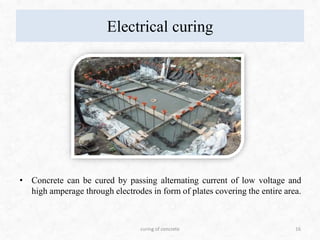

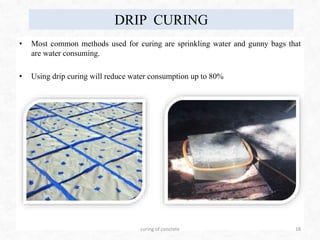

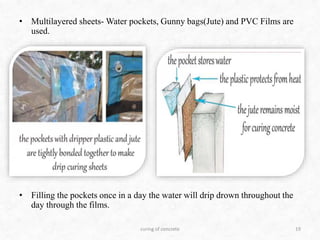

This document discusses various methods of curing concrete, including water curing, membrane curing, steam curing, and electrical curing. It notes that curing allows for continuous hydration and strength gain in concrete. Proper curing retains moisture on the surface and prevents early drying out, leading to increased strength and durability. A new technique called "drip curing" is also introduced, which can reduce water consumption during curing by up to 80% through the use of multilayer sheets that drip water onto the concrete surface.