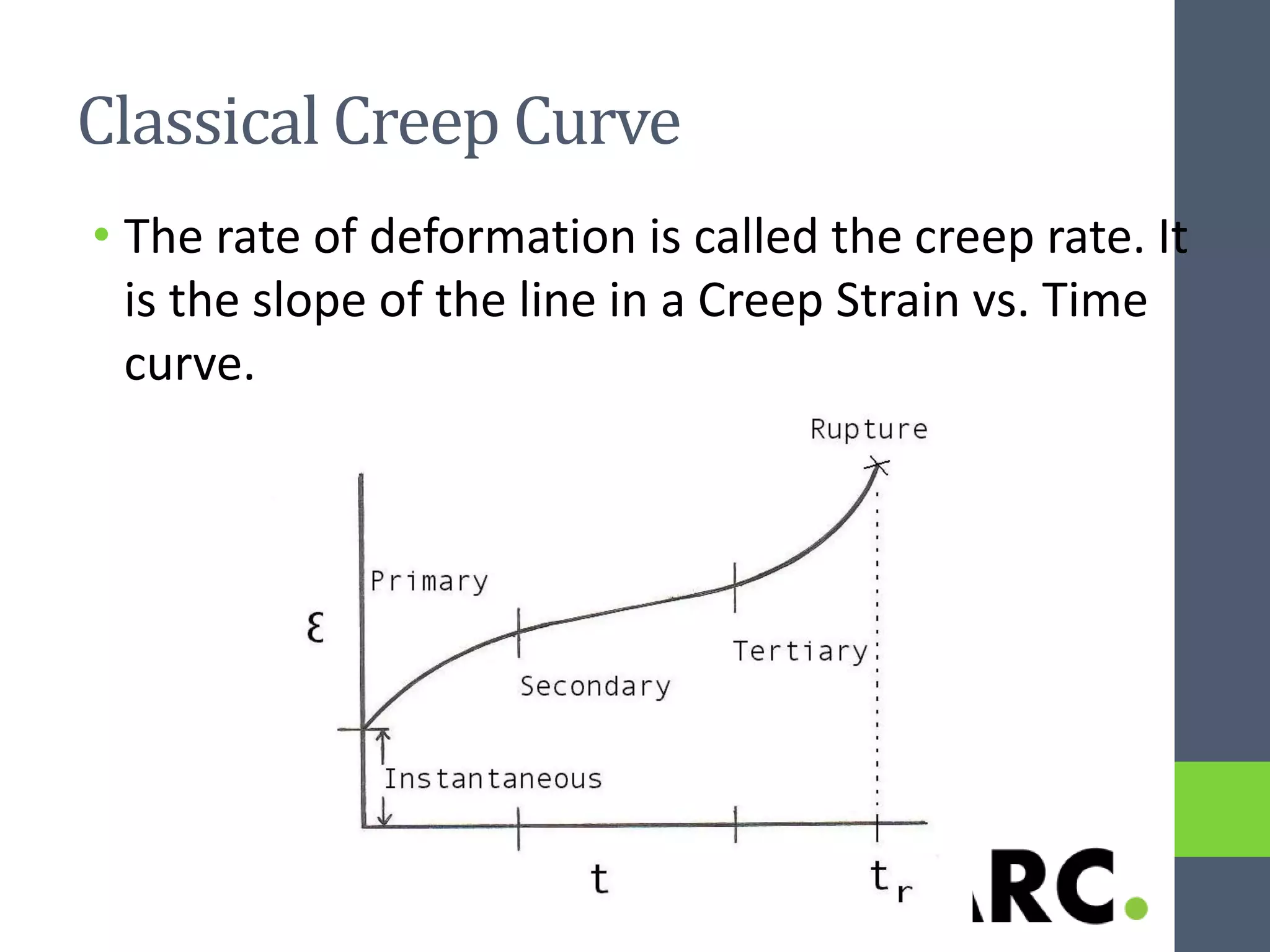

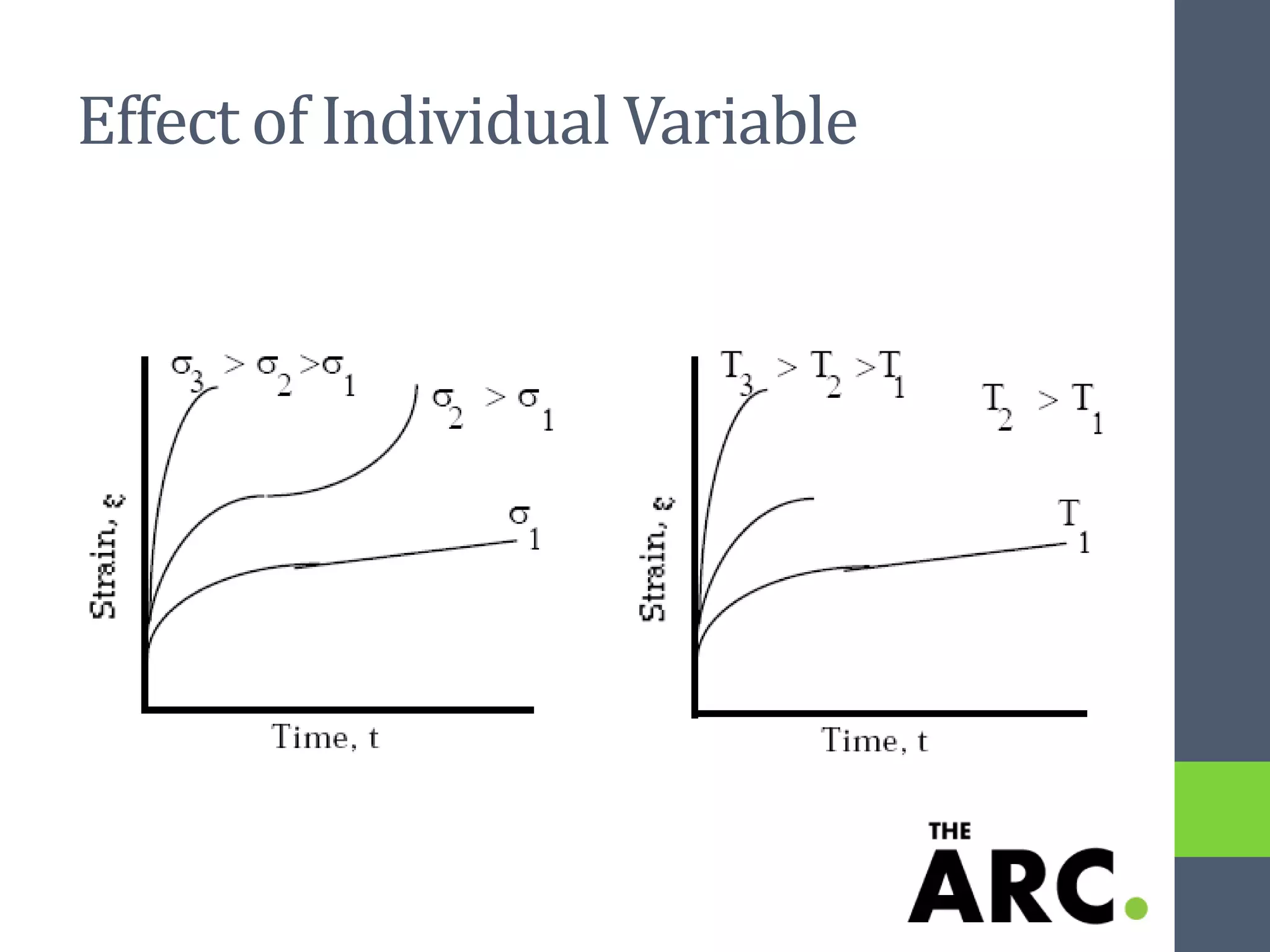

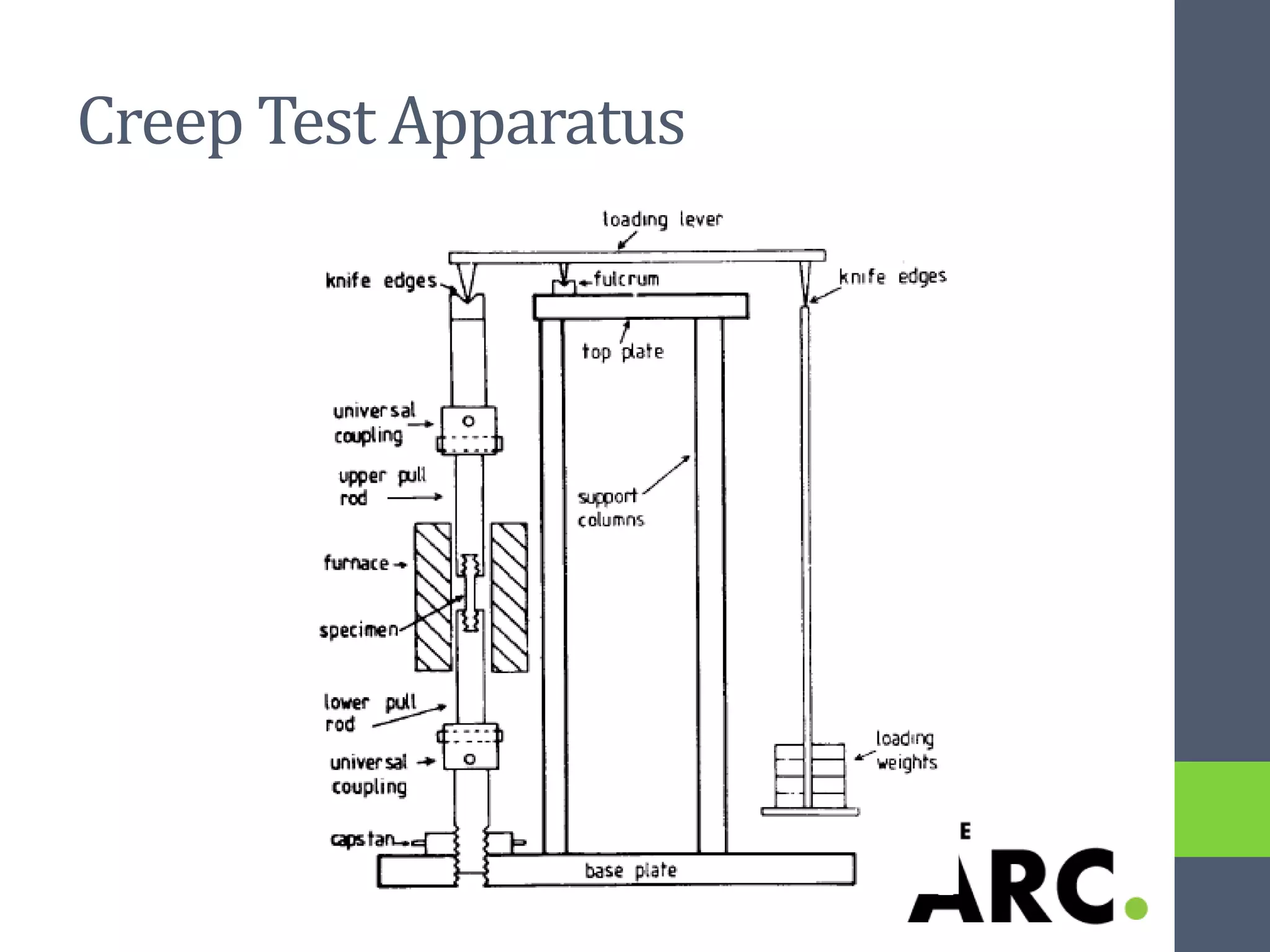

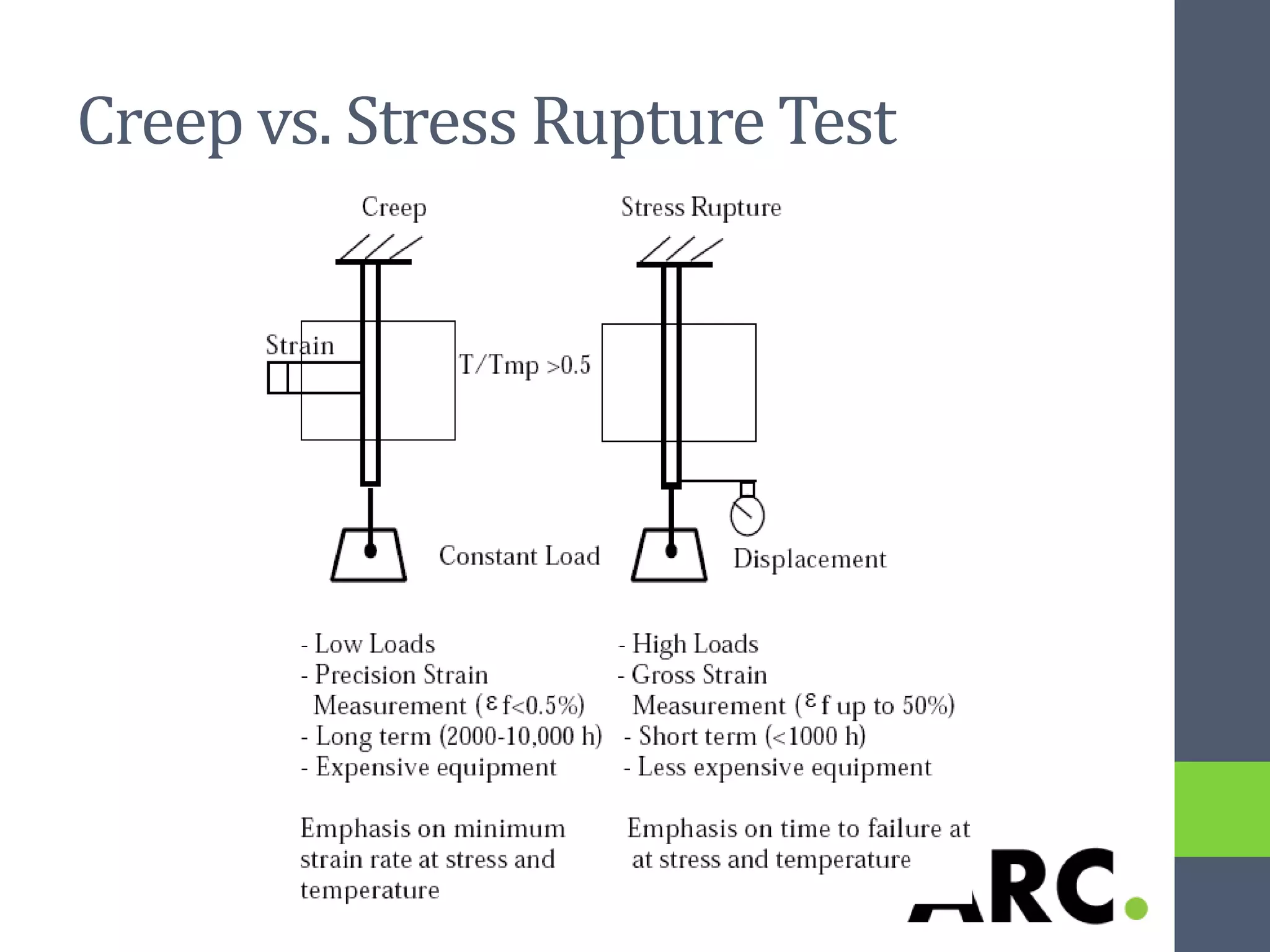

This document discusses creep deformation in materials. It defines creep as time-dependent deformation under an applied load, typically occurring at high temperatures. The main mechanisms of creep are described as bulk diffusion, grain boundary diffusion, and dislocation climb. Classical creep curves consist of primary, secondary, and tertiary creep stages. Factors that influence creep include temperature, stress, grain size, and dislocation movement. Common tests to characterize creep properties are described, such as constant-load tests and stress rupture tests. Design considerations to minimize creep include reducing grain boundaries, using high melting temperature materials, and employing creep data for material selection and inspection intervals.