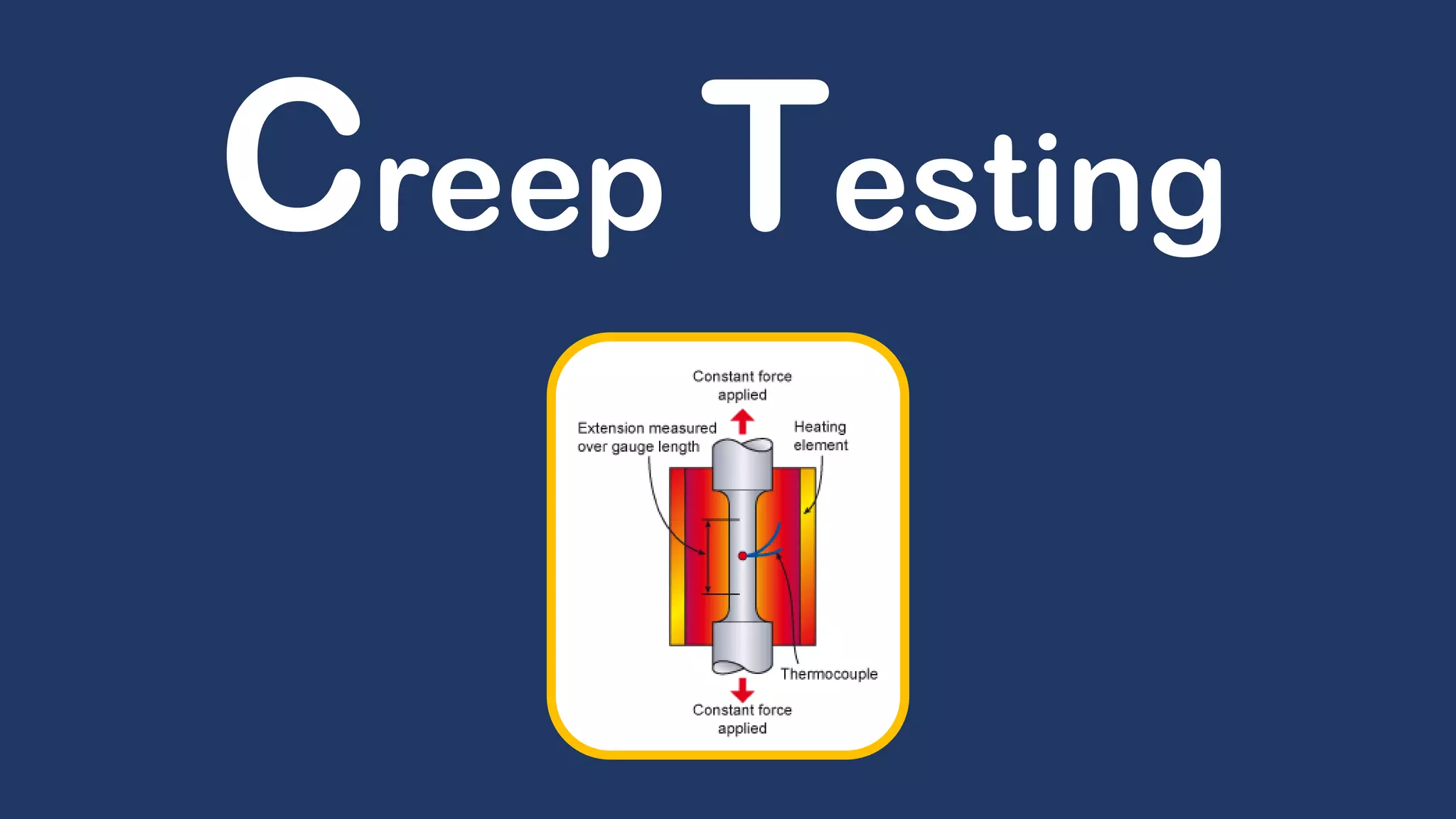

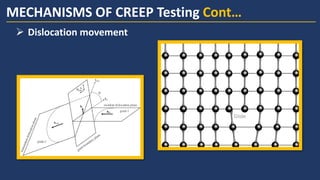

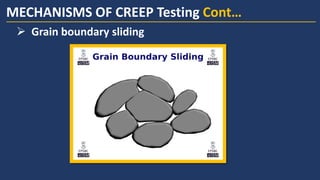

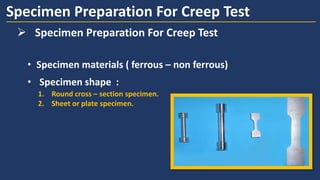

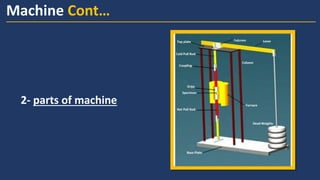

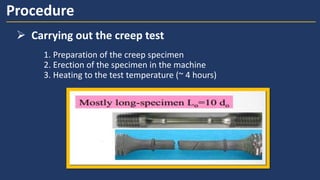

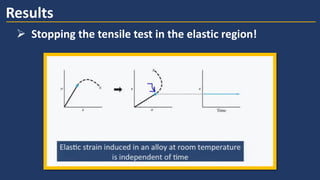

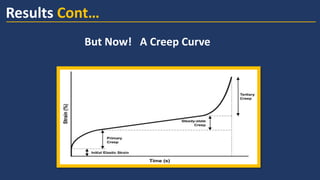

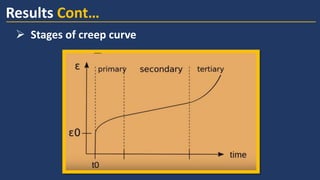

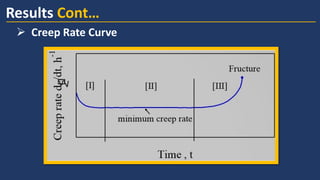

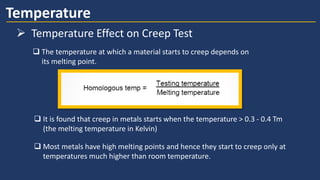

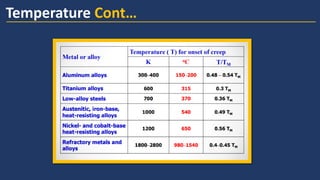

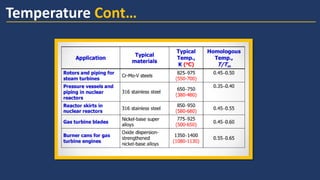

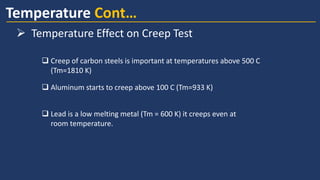

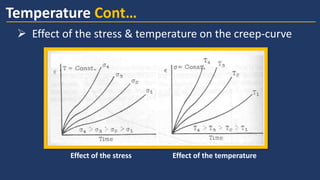

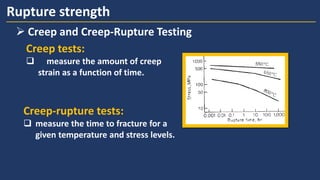

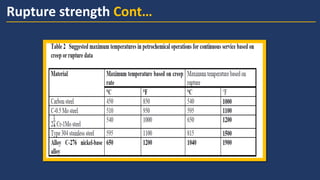

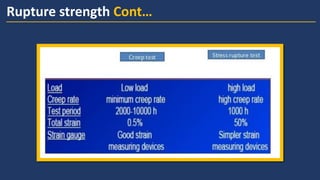

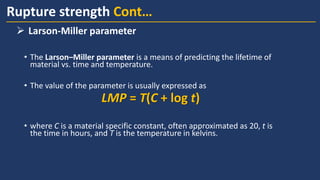

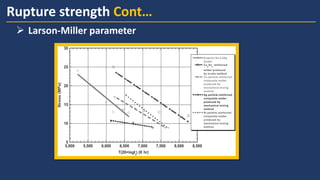

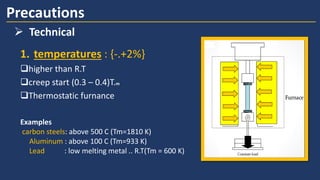

This document outlines the process for creep testing. It discusses the mechanism of creep, specimen preparation, testing machines, procedures, results including creep curves, and the effect of temperature. It also covers rupture strength measurement using the Larson-Miller parameter and precautions for the testing process. Applications of creep testing in industry include displacement-limited components like turbine rotors, rupture-limited parts like steam pipes, and stress-relaxation-limited uses such as suspended cables.