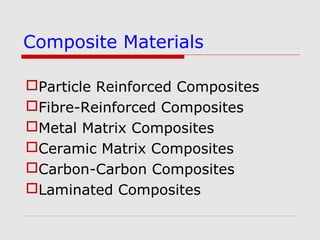

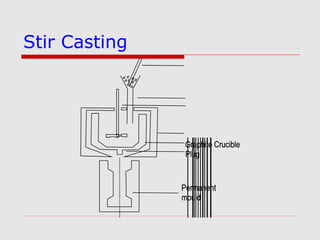

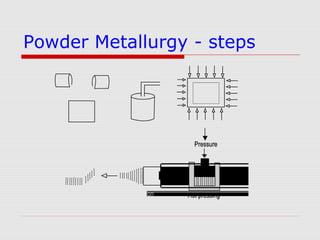

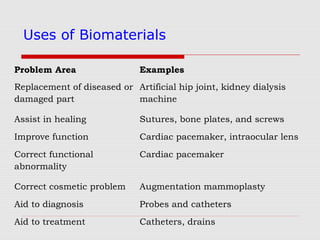

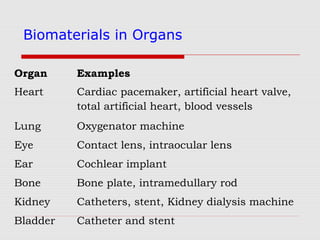

The document discusses various types of composite materials including particle reinforced composites, fiber reinforced composites, metal matrix composites, ceramic matrix composites, carbon-carbon composites, and laminated composites. It also describes common fabrication methods for metal matrix composites such as stir casting, powder metallurgy, and filament winding. Finally, it provides an overview of biomaterials and smart materials, highlighting examples and properties of polymeric, metallic, ceramic, and composite biomaterials as well as piezoelectric and shape memory materials.