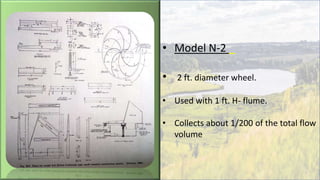

This document describes the design and use of the Coshocton wheel sampler and multi-slot divisor for measuring runoff and soil loss from small plots. It discusses the standardized models (N-1, N-2, N-3) of the Coshocton wheel sampler that collect different proportions of total flow volume based on their diameter. It also explains the key components and installation of the multi-slot divisor system used to collect a portion of runoff into a storage tank for analysis of sediment quantity.