1. Corrosion is the degradation of materials like steel through chemical or electrochemical reaction with surrounding media like water and oxygen, forming rust (iron hydroxide).

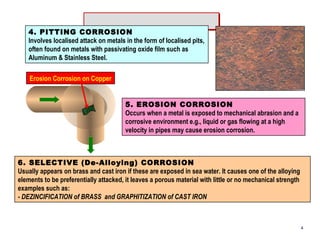

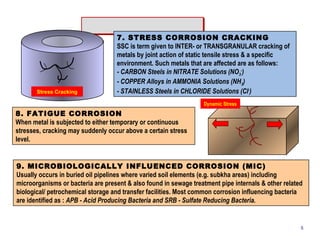

2. Several types of corrosion are described, including uniform corrosion, galvanic corrosion, crevice corrosion, pitting corrosion, erosion corrosion, stress corrosion cracking, fatigue corrosion, and microbiologically influenced corrosion.

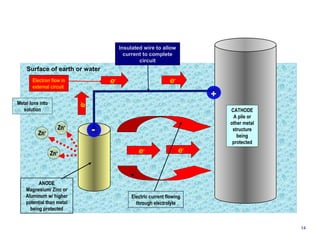

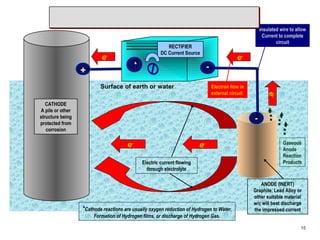

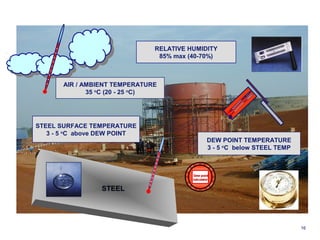

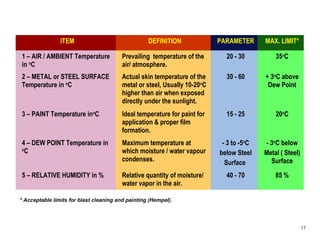

3. Methods to mitigate corrosion include protective coatings like paint and cathodic protection systems that use sacrificial anodes or impressed current to redirect corrosion to the anode from the protected structure. Surface preparation, coating selection, application, and achieving the proper dry film thickness are important.

![CORROSION is the degradation of materials by reaction with surrounding

media through chemical or electrochemical process

STEEL (IRON), Fe

WATER

H2O

WATER

H2O

OXYGEN

OXYGEN

O2

O2

RUST, Fe (OH)

Cathode Site : 2 H2O + O2 + 4 e -> 4 OH-

[Water + Oxygen + Electron (Iron) = Hydroxyl Ions]

Cathode Site : 2 Fe++ + 4 OH- -> 2 Fe (OH)2

[Iron Ions + Hydroxyl Ions = Ferrous Hydroxide]

Anode Site :

2 Fe (OH)2 + H2O + ½ O2 -> 2 Fe (OH)3

[Iron Hydroxide + Water + Oxygen = Iron

Hydroxide (RUST)]

1](https://image.slidesharecdn.com/001prz-corrosionprocessandcontrol-141111003052-conversion-gate01/85/Corrosion-Process-and-Control-2-320.jpg)

![Cathode (+) Cathode (+)

e- e-

Anode (-)

Acid Solution Droplet

Iron (Fe+++) Ions

Hydrogen Gas

2 H+ + 2 e- H2

[ Acid Solution + Iron Ion = Hydrogen Gas ]

2](https://image.slidesharecdn.com/001prz-corrosionprocessandcontrol-141111003052-conversion-gate01/85/Corrosion-Process-and-Control-3-320.jpg)

![1. UNIFORM (General)

CORROSION

Corrosion that develops at approximately the same

rate over the entire metal surfaces.

Steel

[Ignoble]

Corrosion on Steel 2. GALVANIC (Bimetallic)

Brass

[Noble]

CORROSION

Occurs when there is metallic contact between two dis-similar

metals in a corrosive environment.

Water more rich in Oxygen

becomes the Cathodic

region

Crevice becomes the

Oxygen depleted area, i.e.

Anodic region

Corroding Area

3. CREVICE CORROSION

Narrow crevices exposed to a liquid, typically water

containing solutions, may be open enough to allow the

liquid to penetrate, but still narrow that liquid becomes

stagnant & crevice corrosion occurs. The driving force

is the difference in Oxygen content inside & outside the

crevice.

3](https://image.slidesharecdn.com/001prz-corrosionprocessandcontrol-141111003052-conversion-gate01/85/Corrosion-Process-and-Control-4-320.jpg)