This document provides information on various machines used in the cotton processing industry:

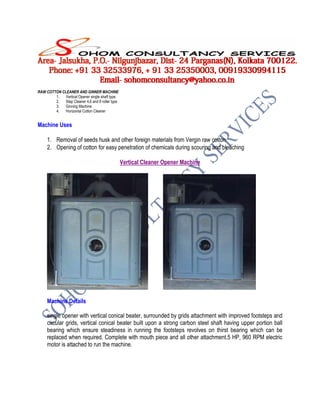

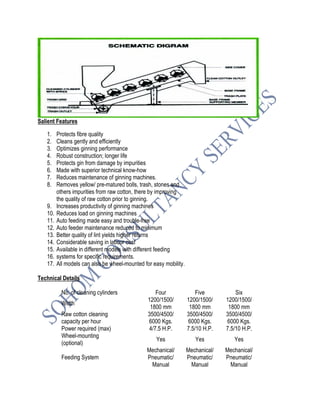

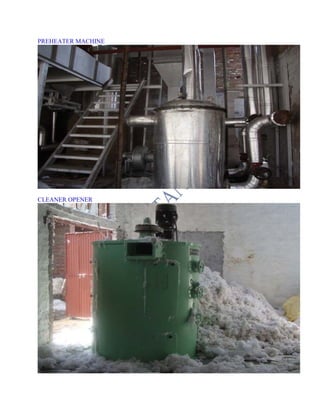

1. It describes machines for opening, cleaning, and ginning raw cotton like vertical openers, step cleaners, ginning machines, and horizontal cotton cleaners.

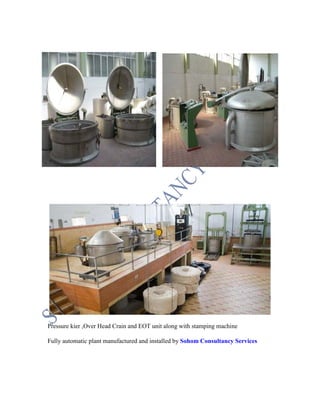

2. It then covers scouring, bleaching, and drying machines like pressure kiers, preheaters, hydroextractors, and chamber or conveyor dryers.

3. Finally, it mentions carding machines that card cotton, man-made fibers, and blends to produce sliver.