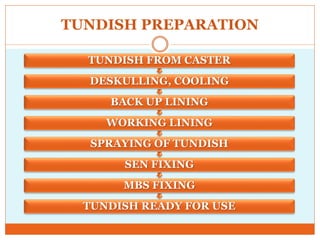

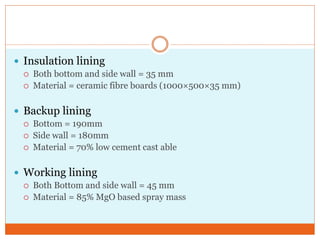

This document summarizes the process of preparing a tundish for continuous casting of steel. It discusses what a tundish is, the different lining layers including insulation, backup, and working linings. It details the steps to deskull, cool, and apply each lining layer. Key tundish furniture like the submerged entry nozzle and stopper are also described. The final steps of preheating the tundish and attached equipment before use in continuous casting are outlined.