Embed presentation

Download to read offline

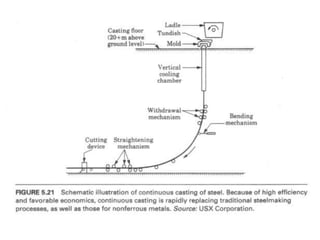

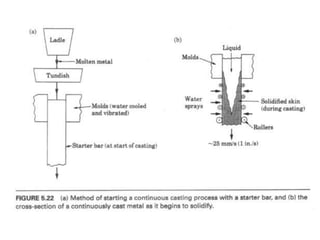

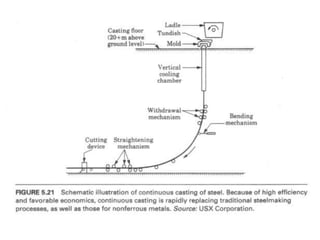

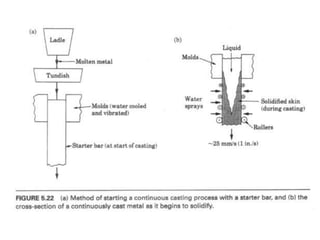

Continuous casting was conceived in the 1860s and has since led to major improvements in efficiency, productivity, and cost reductions for metal production. The process involves cleaning and equalizing molten metal in a ladle before pouring it into a tundish where impurities are removed, then the metal travels through water cooled copper molds to begin solidifying as it moves downward along supported rollers. The key advantages are 100% casting yield due to no waste metal, an automatic and consistent process, and reproducible mechanical properties, though it requires significant floor space and cooling and is not suitable for small quantity production.