This document provides an overview of continuous casting of copper-based alloys and precious metals. It discusses the history and evolution of continuous casting machines and processes. It describes different types of continuous casting including vertical, vertical upward, and horizontal casting. It also discusses crucibles, furnaces, casting dies, cooling systems, and safety aspects of continuous casting operations. Finally, it reviews the continuous casting of specific metal alloys like copper, brasses, bronzes, nickel-silver, and precious metals.

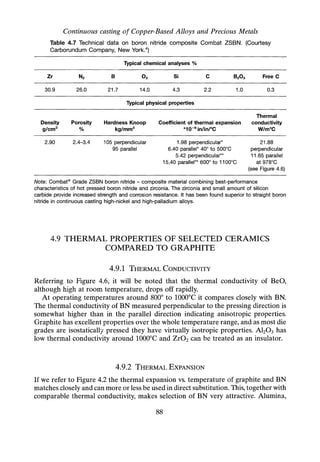

![Continuous casting of Copper-Based Alloys and Precious Metals

used, and as would be expected a 'thermally turbulent' zone is created, resulting in

poor heat transfer from the inner surfaces of the rods. In horizontal casting the

resulting oval-shaped isotherm exaggerates defects such as hot tearing, and in tin

bronzes inverse segregation tends to be more pronounced on the inner surfaces.

Jacket-cooled dies are limited to slower casting speeds.

In probe-cooled dies heat transfer is predominantly axial. The design is very

versatile and now used extensively on small-section rod, tube and strip. From the

heat transfer aspect it is not highly efficient and it is limited in casting speed. Refer

to Section 1.6.3 for further details.

2.2 OVERALL ENERGY BALANCE FROM

PROPERTIES OF MATERIALS

The thermal efficiency of the operation can be assessed by determining the

enthalpies of the liquid and solid metal ingot, and the corresponding water coolant,

using these in a simple, heat balance equation. The total quantity of heat which has

to be removed from the liquid/solid metal, within the die, is composed of superheat,

latent heat, specific heats and heat contained in the solid metal due to its

temperature. There may be a certain amount of heat due to solid-phase transforma-

tions but this would be small and can be ignored.

The overall heat balance, within the die and cooler assembly, can be represented

by the heat passing in the direction of metal flow and the coolant passing in the

opposite direction. The total enthalpy of the metal can be balanced against that of

the coolant by applying the equations outlined below.

The total heat derived from the liquid/solid ingot is:

SHM SmM

---at = ---at [CI(Oc - Om) + Lc + Cs(Om - Ox)] (2.1)

The quantity SmM/St represents the weight of metal cast per unit time and is

referred to as the 'casting rate'. It is generally more convenient to use the term

'casting speed' V, which is the linear velocity of the cast ingot. This is correlated to

the casting rate by:

SmM

--=A·p·V

St

(2.2)

The heat extracted from the metal by the coolant is:

SHW SmW

-- == -- X PW(OW2 - OWl)

St St

(2.3)

pW is unity:. 8~ = wi> (OW2 - OWl)

44](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-60-320.jpg)

![Continuous casting of Copper-Based Alloys and Precious Metals

Table 2.3 Heat balance on continuous cast sterling silver strip.

Material - sterling silver Ag 92.5 wt°/o - Cu 7.5 wt°/o

Heat balance equations:

8HM 8mM

8t = Tt [C/(8c - 8m) + Lc + Cs(8m - 8x)]

8HW

:'M = wt»: (OW2 - 8W1)

(2.1)

(2.3)

Strip

120 mm width x 10 mm thick

Casting speed

Density at 20°C

Density - liquid

Latent heat (Lc)

Specific heat liquid (C~

Specific heat solid (Cs)

Water in - temperature

Water out - temperature

Water flow (wf)

Melt temperature (OC)

Mean liquidus/solidus temperature (8m)

Metal exit temperature (Ox)

Cross section area (A)

8HM

8t

8HW

8t

8HM/8HW

at MX100

120 mm/min

10.366 g/cm3

9.210 g/cm3

27.445 cal/gm

0.070 cal/gm

0.059 cal/gm

12°C

25°C

11.75 litres/min

1025°C

845°C

90°C

12 ern"

2100 cal/sec - 8792 joule

2546 cal/sec - 10,660 joule

82.5%

46](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-62-320.jpg)

![Heat Transfer

Table 2.4 Heat balance on OFHC copper rod.

Heat balance equations:

8HM 8mM

M= Bt[C/(Oc - Om) + Lc + Cs(Om - Ox)]

8HW

:.-- = wt x (OW2 - OW,)

at

(2.1)

(2.3)

Material - OFHC copper

Cu 99.99+%

Rod

Casting speed

Density at 20°C

Density - liquid

Latent heat (Lc)

Specific heat liquid (C~

Specific heat solid (Cs)

Water in - temperature

Water out - temperature

Water flow through cooler

Melt temperature (8C)

Mean liquidus/solidus temperature (Om)

Metal exit temperature (Ox)

Cross section area (A)

Mass g/sec

12 mm diameter

1.50 metres/min

8.96 g/cm3

7.95 g/cm3

49 cal/gm

0.118 cal/gm

0.092 cal/gm

16°C

33°C

15 litres/min

1220°C

1083°C

105°C

1.13 ern"

25.333

aHM

at

aHW

8t

SHM/aHW

st BtX100

3930 cal/sec - 16,454 joule

4250 cal/sec - 17,794 joule

92%

47](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-63-320.jpg)

![Continuous casting of Copper-Based Alloys and Precious Metals

Table 2.5 Heat balance on upcast copper-bismuth alloy LG equivalent

(for casting data refer to Section 5.12.3).

Heat balance equations:

aHM amM

8t = 8t[C/(Oc - Om) + Lc + Cs(Om - Ox)]

aHW

:.-- = wt »: (OW2 - OW1)

at

(2.1)

(2.3)

Material - copper-bismuth alloy

C89844 - LG2 equivalent

Nominal analyses:

Cu% 82 - Sn%, 4 - Bi%, 3 - Ni%, 2 - Zn% 9

Tube

Casting speed

Density at 20°C

Density - liquid

Latent heat (Lc)

Specific heat liquid (C~

Specific heat solid (Cs)

Water in - temperature

Water out - temperature

Water flow through cooler

Melt temperature (BC)

Mean liquidus/solidus temperature (Om)

Metal exit temperature (Ox)

Cross section area (A)

Mass g/sec

0021 mm 10 13 mm

Casting speed 630 mm/min

8.70 g/cm3

7.81 q/crn"

39.05 cal/gm

0.107 cal/gm

0.085 cal/gm

22°C

33°C

17 litres/min

1030°C

880°C

100°C

2.136 ern"

19.515

8HM

at

8HW

at

8HM/8HW

aT atX

100

2363 cal/sec - 9893 joule

3117 cal/sec - 13,050 joule

75%

48](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-64-320.jpg)

![Heat Transfer

Table 2.6 Heat balance on horizontal on palladium-silver alloy strip

(for casting data refer to Section 5.12.3).

Heat balance equations:

8HM 8mM

at = 5t[C/(8c - Om) + Lc + Cs(Om - Ox)]

8HW

:.-- = wi »: (OW2 - OW1)

8t

(2.1)

(2.3)

Material - palladium-silver alloy Nominal analyses 0/0:

Pd 55 - Ag 35 - Sn 8 - others rem.

Strip

Casting speed

Density at 20°C

Density - liquid

Latent heat (Lc)

Specific heat liquid (C~

Specific heat solid (Cs)

Water in - temperature

Water out - temperature

Water flow through cooler

Melt temperature (OC)

Mean liquidus/solidus temperature (Om)

Metal exit temperature (ex)

Cross section area (A)

Mass g/sec

10 mm x 3 mm thick

Casting speed 450 mm/min

10.88 g/cm3

9.76 g/cm3

39.14 cal/gm

0.070 cal/gm

0.057 cal/gm

18°C

32°C

3.0 litres/min

1350°C

1225°C

90°C

0.300 ern"

2.455

8HM

8t

8HW

8t

8HM/8HW

aT 5t

X100

277 cal/sec - 1159 joule

700 cal/sec - 2931 joule

40%

49](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-65-320.jpg)

![Continuous casting of Copper-Based Alloys and Precious Metals

LC)

~

Q)

:0

~

o

..•...•

~

Q)

"t-

Q)

a:

-t

tU

s:

U

en

c

o

~

.2

0..

a.

tU

I

0>

c

~tU

U

en

~

o

~

c

~c

o

o

~

o

"t-

tJ)

~

;;:

~

C1)

c.

c.

o

o

::Jo..

OI

o

CiS

c

N

::J

o

z

c

~::J

o

z

(])

~ "

::J

o

.c

co..'E

cg~~.

o::J(J)

o ::J

o

.c

0..

c

N

::J

o

•

•

O>(])

~.§

"C

0..

0>

-c

O>cn

0>'£ >. A

~~gw

..a «1

•

84](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-100-320.jpg)

![Continuous Casting of Copper-Based Alloys

[6]

[1

[1] steel furnace shell

[2] fixed top plate

[3] movable steel top plate

[4] die cooler assembly

[5] solenoid/stopper

[6] pressure loader

[7] terminal connections &

graphite heating elements

(8] top crucible (melt)

(9] bottom crucible (casting)

[10] freeze/drain plug

[11] dump box

FLOATING GRAPHITE BAFFLE

IN TOP CRUCIBLE

RWD9425C

Fig. 5.7 Pressure upcast furnace assembly. Patents UK and USA.31 Courtesy

Rautomead International, Dundee.

5.5.1 DETAILS OF THE PLANT

As shown in furnace layout Figure 5.7, the twin graphite crucible assembly,

contained within a steel pressure-sealed shell, consists of an upper melt chamber and

a lower casting chamber with integral feed ducts to die recesses. The feed ducts

draining from the base of the crucible are designed to enable more or less complete

cast-out of the melt. A duct is provided at the base of the crucible with water-cooled

freeze plug to drain any surplus metal from the system at the end of a run or to

'dump' the charge if required.

The melt crucible [8] is charged via the pressure loader [6]. This is a twin-

chamber unit with pressure seal allowing intermittent charging of cold metal

without interruption of the pressure-casting programme. The melt is mixed and

homogenised in this crucible, the mixing assisted by means of a floating graphite

baffle. Effective deoxidation of the melt is completed in the top crucible prior to

discharge to the lower casting crucible. The melt is transferred to the bottom casting

crucible [9] by activating a stopper [5]. Under pressure, the melt is raised into the

casting die [4] via integral ducts in the crucible. The furnace is operated as a

multi-die unit. Casting can be quickly terminated and metal drained from the die by

using a pressure-relief valve.

103](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-119-320.jpg)

![Continuous casting of Copper-Based Alloys and Precious Metals

Table 5.5 Data on six-nines copper continuous cast in pressure upcaster.

Charge material specification - six-nines copper with trace element impurities

specified in ppm x 10-1

Ag AI As Bi Cr Fe Mn Ni P Pb Sb Si Sn Zn

35 5 1 1 5 10 1 7 10 5 5 7 7 9

Oxygen analyses on charge material - < 10ppm

Cast rod 6 mm diameter. Trace element analyses in ppm x 10-1

Ag AI As Bi Cr Fe Mn Ni P Pb Sb Si Sn Zn

36 4 1 1 5 11 1 7 9 5 5 11 7 10

Oxygen analyses on cast rod - <4 ppm

Comments: The results indicate that the trace element pick-up on the cast rod is within acceptable

limits with reduced oxygen. The material for fine wire production is for use on high-resolution audio

signal transmission.

Data supplied courtesy Rautomead International, Dundee.

5.5.2 CASTING DATA ON HIGH-PURITY COPPER

The copper is in the form of electron beam refined ingot Cu 99.9999 purity as

specification Table 5.5. It is charged and melted in the upper crucible at a

temperature usually close to 1225°C under argon with furnace at atmospheric

pressure. Sufficient time is allowed for deoxidation.The melt is transferred to the

lower cast crucible by activating the stopper. The furnace pressure is raised to

0.5 bar, transferring metal vertically upwards into the casting dies [4] and thus

starting the casting process. Rod 6 mm diameter can be cast at 250 mm/min using a

pulse length of 3.5 mm. The initial casting run on 5 kg charge was a 'wash run'

intended to condition the crucibles and die inserts, followed by cast of 25 kg. The

analysis of the second run is given in Table 5.5.

5.6 CONTINUOUS CASTING OF Cu: Cd AND Cu: Mg ALLOYS

5.6.1 Cu: Cd ALLOYS

Extensive use is made of copper-cadmium alloys as electric trolley wire. The

material is used as an alternative to oxygen-free copper based on higher strength

while still maintaining high electrical conductivity.

Continuous casting of the CDA alloys C16200 and C16201 in the form of rod is

cast generally in the horizontal mode. More recently the upcast technique has been

applied. Details of the techniques applied to upcasting are given in Section 5.3. Alloy

specification casting data and properties are given in Table 5.6.

104](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-120-320.jpg)

![Continuous Casting of Copper-Based Alloys

Because of the exceptional high toxicity of cadmium, stringent environmental

controls are mandatory, hence the necessity to find suitable alternative material.

5.6.2 Cu :Mg ALLOYS

The alloys listed in Table 5.7 are cast as alternatives to the Cu: Cd alloys mainly

as rod for electrical transmission line and trolley wire. The tensile strength

and electrical conductivity, although not entirely meeting those of the Cu: Cd

alloys, are comparable. Larger-scale production is upcast, using the technique

described in Section 5.3. Alloy specification, casting data and properties are

given in Table 5.7.

5.6.2.1 Continuous Casting of Cu: Mg Alloy Rod

Table 5.8 Continuous casting data on Cu: Mg alloy upcasting - 20-mm-diameter

rod.

Alloy designation Material speCification Physical properties

CuMg05 Mg°A,

0.40-0.70

Others

0.10 max

Liquidus °C

1070

Solidus °C

980

Casting data

Charge materials Cathode copper Cu-Mg master alloy

Casting equipment Upcaster

See section 5.3

Die and cooler assembly

See Section 5.3.1

Graphite die insert

Grade eChapter 4

Tables 4.5 and 4.6

Furnace data Melt temp.

°C

1250

Rod exit

temp.oC

140

Die water

flow IImin

14

Die water

in °C

21

Die water

outOC

33

Casting procedure Cathode copper melted down giving time for deoxidation - Cu: Mg 90: 10 master

alloy (m.p. 750°C density 6.3 g/cm3) added. Plunge to avoid 'burn off' - loss of

magnesium allow +20% addition. The casting parameters set are somewhat

arbitrary and dependent on melt temperature, condition of cast rod. This alloy

exhibits a degree of inverse segregation resulting in pick-up of Mg-rich phase at

the pulse marks - to minimise this the rate of heat transfer should be maximum.

Achieved by short [T = t1 + t2 + t3]. Condition can also be reduced by introducing

a periodic overdwell which allows surface debris to collect and be withdrawn.

Withdrawal f1 sec f2 sec Tsec f4 sec P Pulses Casting

sequence accelrn pull time f1 + f2 + fa pause mm per min speed

AC servo drive fa mm/min

deceln

0.12 0.15 0.27 3.1 14 18 260

Data supplied courtesy Rautomead International, Dundee.

107](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-123-320.jpg)

![Continuous casting of Copper-Based Alloys and Precious Metals

DZR brasses was undertaken by BNF.18 In their equilibrium studies the range of

composition within which an acceptable alloy can be made depends on the location

of the a/a + {3 phase boundary in the Cu-Zn alloys containing Pb, As and normal

commercial impurities.

The BNF study suggested a 'zinc equivalent formula' similar to the Guillet"

method; their study indicates that an alloy with Z% zinc, TO/o tin, A % arsenic and

L% lead has the same constitution as a copper-zinc alloy with:

[

Z + 2T + 3A] 1000/ .

100 - L 10 ZInc

In this formula the tin and arsenic behave as two and three times their own weight

of zinc respectively, lead acts as a diluter and any other trace elements present can

be considered as copper.

5.7.8.1 Continuous Casting of DZR Brass

Continuous casting of dezincification-resistant a brass is the same as for conven-

tional single-phase brass as outlined in Section 5.7.1. The restricted composition

covered by specification Table 5.11 (CuZn36Pb2As-CW602N) must be strictly

observed to ensure adequate hot stamping properties in the a/{3 temperature range

and also to ensure an all-a structure after heat treatment. The bulk of this material

is cast in the form of rod.

5.8 TIN BRONZES

Tin bronzes are extensively continuously cast, generally as rod, formed section and

tube.

5.8.1 COPPER-TIN ALLOYS

The tin bronzes differ considerably from the brasses insofar as relationship between

thermal equilibria and actual structure in the cast condition. In true equilibrium an

8% tin alloy would solidify entirely as a solid solution. In practice under normal

casting conditions the wide freezing range causes extensive segregation to occur and

the last liquid to solidify is so enriched in tin that it freezes by peritectic reaction at

798°C to form {3. On cooling further the f3 transforms again.

Examining the binary Cu-Sn diagram (Figure 5.12) in equilibrium there would be

a series of eutectoid reactions where f3 would transform to a and l' at 586°C (HIJ),

then the l' would transform to a and 8 at a temperature of 520°C (KLM) and finally

the 5 would transform to a and e at 350°C. In practice the phase normally

encountered in the cast structure is a + 5 eutectoid. The 5 ~ a + B reaction proceeds

very slowly and e would appear only under prolonged low-temperature heat

treatment.

122](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-138-320.jpg)

![Continuous Casting of Precious Metals

Au SOLIDUS ISOTHERMS OF THE

Au-Ag-Cu SYSTEMS at

[a]1DOOC [b]9S0C [cJ900C

[dJ850C [e J80De

60

[c]900C

40

20

COMPOSITIONS EXPRESSED IN

ATOMIC 70.

[d]850C

Cu

[e]800C

Fig. 6.7 Solidus projection fo Au-Ag-Cu system.

6.8.1 LIQUIDUS ISOTHERMS Ag-Au-Cu SYSTEM

Referring to Figure 6.6, the liquidus temperatures have been determined for the

carat Au-Ag-Cu alloy compositions listed in Tables 6.4, 6.6, 6.7 and 6.8. Although the

accuracy of liquidus isotherms is in the order of ±5°C the values listed against

specific compositions are relative and intended as an approximate guide for

continuous casting purposes. For precise accurate liquidus/solidus temperatures one

is required to adopt thermal analyses techniques on similar continuous cast

samples.

6.8.2 SOLIDUS ISOTHERMS Ag-Au-Cu SYSTEM

Referring to Figure 6.7, solidus isotherms for the Ag-Au-Cu systems at: [a] 1000°C;

[b] 950°C; [c] 90QoC;[d] 850°C; [e] 80QoChave for simplicity been incorporated into

a single graph. From these data the solidus temperatures have been determined for

the appropriate Au-Ag-Cu alloy compositions in a similar way to the liquidus

temperatures. The reservations as to the precise accuracy also apply in this case

when referring to actual continuous casting conditions. It can be noted, however, if

169](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-185-320.jpg)

![Continuous Casting of Precious Metals

WEIGHT PER CEN; GERMANIUM

10 15 20 30 40 50 60 70 80 90

900

I

, , I I , -, I J , -,

1:3

0

i I I 1

I I

I

I

I I

I

I

/

I

1

IT

~

I

I ~

I

I

1

-:

I I

I

t>

I

/'

I

I

I

I

I

V

I ~

~ /

I

•• I

I

I

I

1 1

.l' I

VI I I

I

I

I

l ! !

I VI

----

I

n 3560

-

1(3..2(1.2)

...,

27

!

I

(121

0.2 to.on

1100

1000

800

-

~ 700

=>

•...

<

0:

~ 600

3:

w.t

500

(Au)

400

300

200

o

Au

10 20 30 40 50 60 70

ATOMIC PER CENT GERMANIUM

80 90 100

Ge

Fig. 6.20 Au: Ge diagram (after Hansen).

The casting procedure adopted in the case of the Au: Ge alloy is essentially the

same as used on the Au: Sn eutectic alloy.

As indicated in the Au : Ge diagram, Figure 6.20, the alloy system forms a simple

eutectic at 12 wt% Ge at 356°C. A melt temperature of 450° to 500°C would be used.

In both the Au: Sn and Au :Ge alloys the vapour pressures are such that there are

no significant volatiles at the melt out or at operating temperatures.

6.15.4.3 Casting 98:2 Au-Si Alloy

Au-Si forms a gold-rich eutectic at 6 wt% Si at a temperature of 370°C. The

Au-Si2% has an extremely wide freezing range 980°-370°C, see Figure 6.21. This

makes the alloy difficult to cast with tendency to hot tearing. The withdrawal settings

mentioned in Chapter 1, Section 1.7, will favour longish slow pull stroke [t1 --+ t3] with

extended [t4]. On copper plate strip cooler, adjust cooling pattern, with 'grafoil' as

required. Adequate outward top taper is required on the graphite die. The metal

temperature entering the die should be around 1100°C.

The Si addition makes the alloy somewhat aggressive to graphite, therefore it is

necessary to select one of the grade e die graphites with high thermal conductivity.

The casting rate on a 60 mm X 6 mm strip could be around 75 mm/min.

189](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-205-320.jpg)

![Continuous casting of Copper-Based Alloys and Precious Metals

substituting part of the copper with up to 4% Cd. In this exercise comparison is

made between Ag: Cu-Ag :Cu: Cd and Ag: Cu :Sn :Mg sterling silver alloys.

The pressure up caster was used primarily because of the high toxicity of

cadmium, with a pressurised and sealed system, venting the exhaust gas via a water

trap. The atmospheric contamination, monitored over the entire casting cycle, was

held well within the international MEL (maximum exposure limit) of 0.05 mg m ?

Cd, calculated over an 8-hour period.

6.18.4.1 Casting Data

The casting operation consisted of melting and stabilising the alloys under inert

atmosphere at a furnace temperature of 1050°C and atmospheric pressure. Prior to

casting, the furnace pressure is increased to around 0.5 bar above atmospheric

pressure, thus raising the molten metal into the die, and after allowing time for the

die assembly to attain thermal stability casting commences. In this study the various

alloys were cast in the form of 9 mm X 3 mm strip with a pulse length around 4-5 mm

at a casting speed in the range 0.3-0.5 mlmin. At the end of one casting cycle, on one

alloy, pressure is lowered to atmospheric, the system is drained, charged with a

second alloy and a repeat sequence initiated.

6.18.4.2 Properties of the Cast Strip

The UTS and elongation were measured on the as-cast strip, and after reduction by

cold rolling are presented in Figure 6.23.

metal expressed in parts per thousand

700~------------~------------~------------~------------~

--+-Alloyl

~~··lg [ ~~.~~

500 ----L-----_-..,..J"---------------- ..-.. --.-------.:--.---

-------·-----··----~-~-:,-f--~-~-----·:~-;·-~··-·:---·-·-

600 -.. -

re 400

e

Z

.5

r'-J

~ 300

~1] Ag 925 Cu 75

200 -. -. -. - -. -'. -- -_.--- ---- ---- ---- -!f-I~.?~~-~-~-~?-~~-~-~~- ~-.-----:---.- ----.----- ----.-'" --.. ------.------------------ .--------------

(F1 Ag 925 Cu 52 Sn 20 Mg 3 :

100 .. ;::.: ~~~.~:. ~~::: ~g ~"'r"""""'" . .

o

20 40 60 80

AS CAST % Cold Reduction

Fig. 6.23 Sterling silver (modified specification) UTS vs. % cold reduction.

196](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-212-320.jpg)

![Continuous Casting of Precious Metals

metal expressed in parts per thousand

~~------------~-----------------=========~======----~

[11Ag 915 Cu 75

~ ---"- -c-.-~-----------------------

~~ 'III

.-:..,

". '., [31Ag 9l5Cu 52 Sn 20 Mg 3

~ 'L•• _:: ~.-j(~---------------------------------:------------------------- L.----.,... -.....J

----------------------"(21Ali 925-eil 67 SU-5-M2 3 -----

---+- Alloy 1

..•..Alloy 2

_ .•... Alloy 3

..*.. Alloy 4

_.l(- Alloy 5

[41Ag915 ~u 32 Sn 40 Mg 3

. ,'. ,

---------- ---- ----------------- -:-x-- ---------'-,- ----- --- ------------ ~----------------------- ------------;------ ------- ----- ----------------

; ". " [51Ag92S Cu35 Cd 40 :

:. -. .

,

-...------------------------------~---------------~~.------~,--------:-- --------------------------------,-------- --------------------------

~ i' ".!

: ::'·:·'··'·':;·':·.~:~t.~.·.~::~.·.~

...

~.:~~·~..:.I,;:~:~~~;

..;~~.:.~~:;~~~;

':~7.~.7~:~:;~

'.

Q~--------~--------~-----------~----------~

AsdlsT ~

% Cold Redaction

Fig. 6.24 Sterling silver 925 (modified specification) elongation vs. % cold reduction.

Referring to the mechanical properties shown in Figures 6.23 and 6.24, the tensile

strength of the as-cast alloys is comparable, with a slightly increased average on the

modified alloys. The ductility, measured by elongation, is considerably higher in

alloys [4] and [5], i.e. the 40/0 Sn-0.35 Mg and the 40/0 Cd specifications. Deep drawing

production trials corroborate these findings.

6.18.5 Ag: Cu EUTECTIC ALLOY AND SIMILAR ALLOYS

As indicated in Figure 6.22, a eutectic is formed at 28.1 wt% Cu at a temperature of

779°C between a silver-rich solid solution containing 8.8 wt% Cu and f3 copper-rich

solid solution containing 92 wt% Cu.

This alloy has the best combination of strength, hardness and electrical properties

of any of the Ag :Cu alloys. It is used extensively for contact material in electronics.

There are a number of variants of this alloy Ag: Cu 90 :10-80: 20-75 :25 for specific

applications; these alloys have a freezing range and all cast without difficulty.

6.18.5.1 Casting Equipment

A large quantity of silver-copper alloys are cast in the horizontal mode as strip in

sizes ranging from around 50 mm width to 300 mm width. The width-to-thickness

197](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-213-320.jpg)

![~

(J)

0-

0..

o

o

"'0

(J)

.Q

(ij

3:

.Q

"'0

C

~

~

(])

0.

0..

o

o

Z

(5

><

CO

E

~

o

Cl)

C)

e

g

e

o

~

'iii

e

c.

E

o

o

.c

c.

OO"-::J

~~(J

(J(JI

I I U.

wwO

00

""""""

00

dd

I I

LOLO

00

~O

od

00

c.

Cl)

II.

'0

o

Appendix 1

('t)('t)LOLO

0000

dddd

00"1"-

~t?19

~OLO('t)

~dd

LOOO

dd

I I

('t)LO

dd

OOLOLO

~~CICI

dddd

0000

LOOOO

OClClLO

O~~O

9999

LOOOLO

ClOOOOCl

0000

dddd

::::s

o

+-' +-' +-'

en en en

Q) Q) Q)

a: a: a:

•..

Cl)

.c

E

::::s

z

1;)1;)1;)1;)

Q) Q) Q) Q)

a: a: a: a:

~g~R~~~8m~~~R~~~~~~~~ID~~

OOOOOOClCl ClCICICI('t)('t)('t)('t)LOLO",,"LO~CI~'J

oooooo~~~~~~~ ~ ~~ ~~~o~

NNNNNNNNNNNNNNNNNNNNNNNN

"0

.c

E

~

245

~

'I

~ 0

d CI

C C L09

NN

~ClLOO

dddd

('t)

o

d](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-261-320.jpg)

![Continuous casting of Copper-Based Alloys and Precious Metals

•..

o

Cl)

C)

c

g.

';fl.

e

o

••

"(;;

o

Q.

E

o

o

f

Cl)

.c:

o

00000000

"""~N",,"N,,,,"CJ~

00000000

OOOOOCV:>CJ

CV:>C")C")NCJOO

0000000

.c

Il.

LOLOLOI'---LO"""LO"""

00000000

Cl)

LL.

CV:>LOCV:>CV:>CV:>CV:>CV:>CV:>

00000000

c

N

1i51i51i51i51i51i)ti1i5

(]) (]) (]) (]) (]) (]) (]) (])

a: a: a: a: a: a: a: a:

:::s

o

•..

e

.c

E

:::s

z

"0

.c

E

~

248

~

.c

0>

::J

e

3:

z

o

It)

,..

><

co

E

•..

o

e

C)

c

g.

?f!.

e

o

~

"(;;

o

Q.

E

o

o

e

Cl)

.c:

s

00000

~NCJNCJ

00000

e

UJ

LOLOLOOO

~1r-r~r-r

qLOLOLOO

Mt.ri~t.ri

.c

e,

LOLOLOLOLO

00000

00000

LOLOLOLOO

cv:>cv:>cv:>cv:>~

00000

I I I I I

00000

00000

00000

CJCV:>CV:>CV:>CV:>

00000

e

LL

00000

~ ~,.....

00000

c

N

a

ggggr-f

00000

t.ri

E E E E E

(]) (]) (]) (]) (])

a:c::a:c::a:

•..

Cl)

.c

E

:::s

Z

0<.0000

oo~oo

~ ~ ~

C'JCiCiC'JC'J

(5

.c

E

l;](https://image.slidesharecdn.com/apracticalapproachtocontinuouscasting-robertwilson-230430074453-bf653c23/85/A-practical-approach-to-continuous-casting-264-320.jpg)