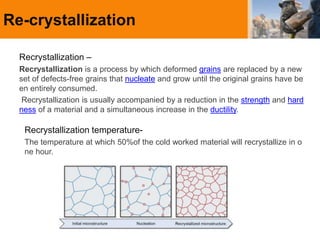

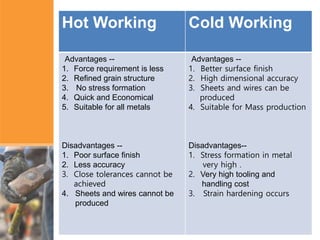

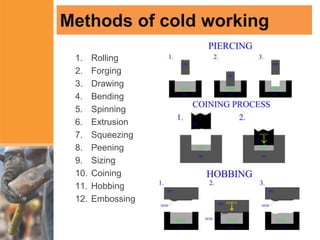

This document discusses forming processes used in mechanical engineering. Forming involves reshaping metals through mechanical deformation without adding or removing material. It can be done through hot or cold working. Hot working is above the recrystallization temperature while cold working is below it. Advantages of forming include negligible waste and possible grain orientation. Disadvantages include high force requirements and limitations producing parts with holes. Various forming methods for both hot and cold working like rolling, forging, drawing, and extrusion are also outlined.