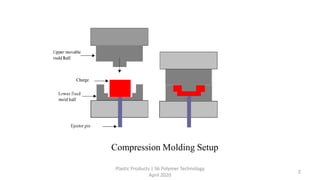

Compression molding is a process where molten plastic is squeezed into a heated mold under high pressure. It is commonly used for thermosetting plastics like phenolics and urea-formaldehyde. The material is placed in an open mold and compressed until it hardens. This process is slower for thermoplastics which must be cooled before ejection. Compression molding produces parts with good surface finish and wastes little material.