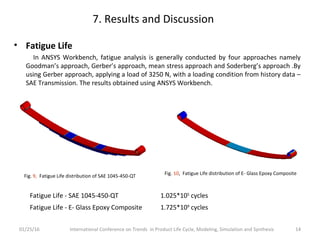

This document presents a study comparing the fatigue performance of a steel leaf spring and a glass fiber/epoxy composite leaf spring used in automobiles. A finite element model was created of each leaf spring using ANSYS software. Static analysis showed the composite spring had higher stiffness but similar maximum stress compared to the steel spring. Fatigue analysis using the Gerber approach predicted the composite spring would have a longer fatigue life of 1.025*10 cycles compared to the steel spring. The document concludes the composite spring design and simulation validate methods for predicting fatigue performance without full physical testing.

![2. Background

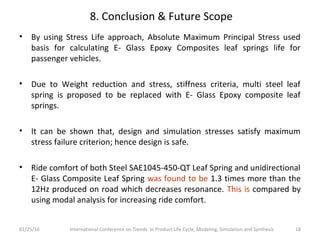

Author Conclusion

Senthilkumar

Mouleeswaran [2]

Composite multi leaf spring using glass fibre reinforced polymer

compared to steel spring, found to have 67.35% lesser stress,

64.95% higher stiffness and 126.98% higher natural frequency and

also weight reduction of 68.15% is achieved compared to steel leaf

spring.

D.N.Dubey,

S.G.Mahakalkar [7]

Composite leaf springs would offer substantial weight savings by

using mono leaf spring in passenger cars. Mono parabolic leaf spring

of a Maruti Omni used HM and HS Carbon polymers composite

material.

Makarand B. Shirke and

Prof. V .D .Wakchaure [5]

The life of the spring is an important criterion. In this aspect as well

composite leaf spring proves to be much better than EN45 steel leaf

spring.

01/25/16 International Conference on Trends in Product Life Cycle, Modeling, Simulation and Synthesis 4](https://image.slidesharecdn.com/plmsspresentation-160125183502/85/Composite-automobile-leaf-spring-Fatigue-life-4-320.jpg)

![2. Background

Author Conclusion

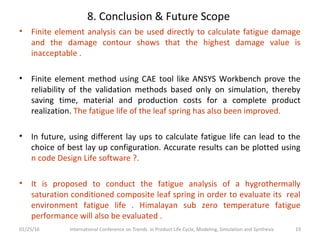

Shishay Amare Gebremeskel

[4]

Constant cross section design of mono leaf springs is employed to

take advantages of ease of design analysis and its manufacturing

process. Resulting design and simulation stresses are much below

the strength properties of the material, satisfying the maximum

stress failure criterion .

Sachin Kr. Patel,

A.K. Jain and

Pratik Gandhi [9]

Composite materials have high elastic strain energy storage capacity

and high strength to weight ratio Therefore, composite leaf spring is

an effective replacement for the existing steel leaf spring in

automobile.

J.A.M. Ferreira,

J.D.M. Costa,

P.N.B. Reis, M.O.W.

Richardson [8]

The fatigue strength is strongly influenced by the layer design.

0° laminate results have values 1.5-1.8 times higher than +45°/0°/-

45° and +30°/-30°/0° laminates which exhibit similar fatigue

strengths.

01/25/16 International Conference on Trends in Product Life Cycle, Modeling, Simulation and Synthesis 5](https://image.slidesharecdn.com/plmsspresentation-160125183502/85/Composite-automobile-leaf-spring-Fatigue-life-5-320.jpg)

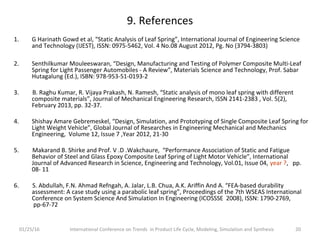

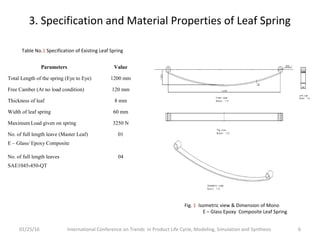

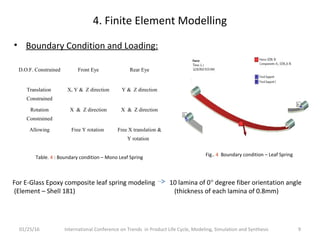

![3. Specification and Material Properties of Leaf Spring

01/25/16 International Conference on Trends in Product Life Cycle, Modeling, Simulation and Synthesis 7

Material Properties Value

Elastic Modulus (E), GPa 207

Yield Tensile Strength , MPa 1515

Ultimate Tensile Strength, MPa 1584

Cyclic Strength Coefficient (K’) 1874

Fatigue Strength Coefficient (Sf) 1686

Fatigue Strength Exponent (b) -0.06

Fatigue Ductility Exponent (c ) -0.83

Fatigue Ductility Coefficient (Ef) 0.79

Cyclic Strain Hardening Exponent (n’) 0.09

Density , Kg/m3

7.7 × 103

Possion’s ratio 0.266

Behaviour Isotropic

Table .2: Mechanical and Cyclic Properties of

SAE1045-450- QT [11,12]

Table .3: Mechanical and Cyclic Properties of E glass/ Epoxy

Composite material [11. 12]

Material Properties Value

Tensile modulus along X-direction (Ex), MPa 34000

Tensile modulus along Y-direction (Ey), MPa 6530

Tensile modulus along Z-direction (Ez), MPa 6530

Tensile strength of the material, MPa 900

Compressive strength of the material, MPa 450

Shear modulus along XY-direction (Gxy), MPa 2433

Shear modulus along YZ-direction (Gyz), MPa 1698

Shear modulus along ZX-direction (Gzx), MPa 2433

Poisson ratio along XY-direction (NUxy) 0.217

Poisson ratio along YZ-direction (NUyz) 0.366](https://image.slidesharecdn.com/plmsspresentation-160125183502/85/Composite-automobile-leaf-spring-Fatigue-life-7-320.jpg)

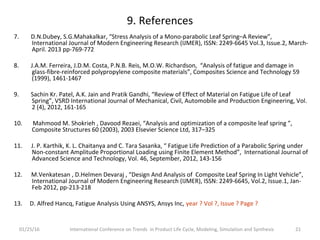

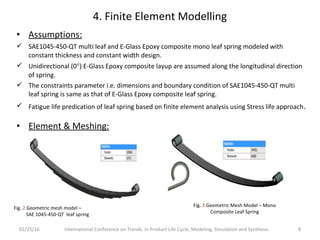

![5. Static Analysis and Ride Comfort

Parameters

Material

SAE1045-

450-QT

E-Glass Epoxy

Composite

Maximum load in N 3250 3250

Absolute Maximum

Stress , MPa

724.52 715

Stiffness, N/mm 24.33 53.59

01/25/16 International Conference on Trends in Product Life Cycle, Modeling, Simulation and Synthesis 10

Table. 5 Comparison result of Stress for

SAE 1045-450 - QT and E-Glass Epoxy Composite

Modes

SAE1045-450- QT

Frequency Hz

E- Glass Epoxy

Frequency Hz

1 13.13 17.15

2 54.55 56.16

3 78.59 72.19

4 116.89 119.36

5 178.49 202.78

6 243.27 288.43

Table 6 Natural frequency of SAE 1045-450-QT and

E-Glass Epoxy Composite material

Static Results :

Shear stress (τ12= 6.77 MPa) multiplied by a factor

of ‘9’ (9*3 = 60.93 MPa) is much less than the

shear strength (S = 68.95 MPa) of the specified

composite material, E-glass/Epoxy.

Specifying the criteria : (9*τ12< S),

Design is safe even for the flexural failure.

Ride Comfort :

To avoid resonant condition The road

irregularities usually have the maximum

frequency of 12 Hz. [7]

In modal analysis only boundary conditions are

applied and no load is acted on the leaf spring.](https://image.slidesharecdn.com/plmsspresentation-160125183502/85/Composite-automobile-leaf-spring-Fatigue-life-10-320.jpg)

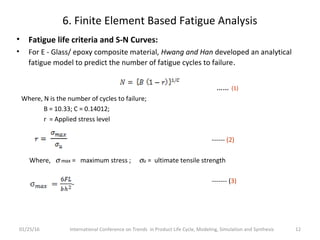

![6. Finite Element Based Fatigue Analysis

• Main purpose of Finite Element Based Fatigue tool using for leaf spring

simulation – during the design stage of development process to enable

reliable fatigue life calculations.

• Input Parameter and Fatigue Analysis Cycle

01/25/16 International Conference on Trends in Product Life Cycle, Modeling, Simulation and Synthesis 11

Figure 5 Fatigue Analysis Prediction Strategies

Figure 6 FEM Based Fatigue Analysis Cycle [11]](https://image.slidesharecdn.com/plmsspresentation-160125183502/85/Composite-automobile-leaf-spring-Fatigue-life-11-320.jpg)

![6. Finite Element Based Fatigue Analysis

• The life data analysis is a tool to be used here to predict the fatigue life of mono

composite leaf spring.

• Fatigue life results are based on analytical result and resulting S-N graph for

SAE1045-450-QT and E – Glass Composite as shown in Fig. 7 and 8

• E glass-epoxy figure is for tension, torsion or bending ? Specify ! ( Figure 7)

01/25/16 International Conference on Trends in Product Life Cycle, Modeling, Simulation and Synthesis 13

Figure 7 S-N curves for E-Glass/epoxy composite [2] Figure 8 S-N curves for SAE1045-450-QT spring [11]](https://image.slidesharecdn.com/plmsspresentation-160125183502/85/Composite-automobile-leaf-spring-Fatigue-life-13-320.jpg)