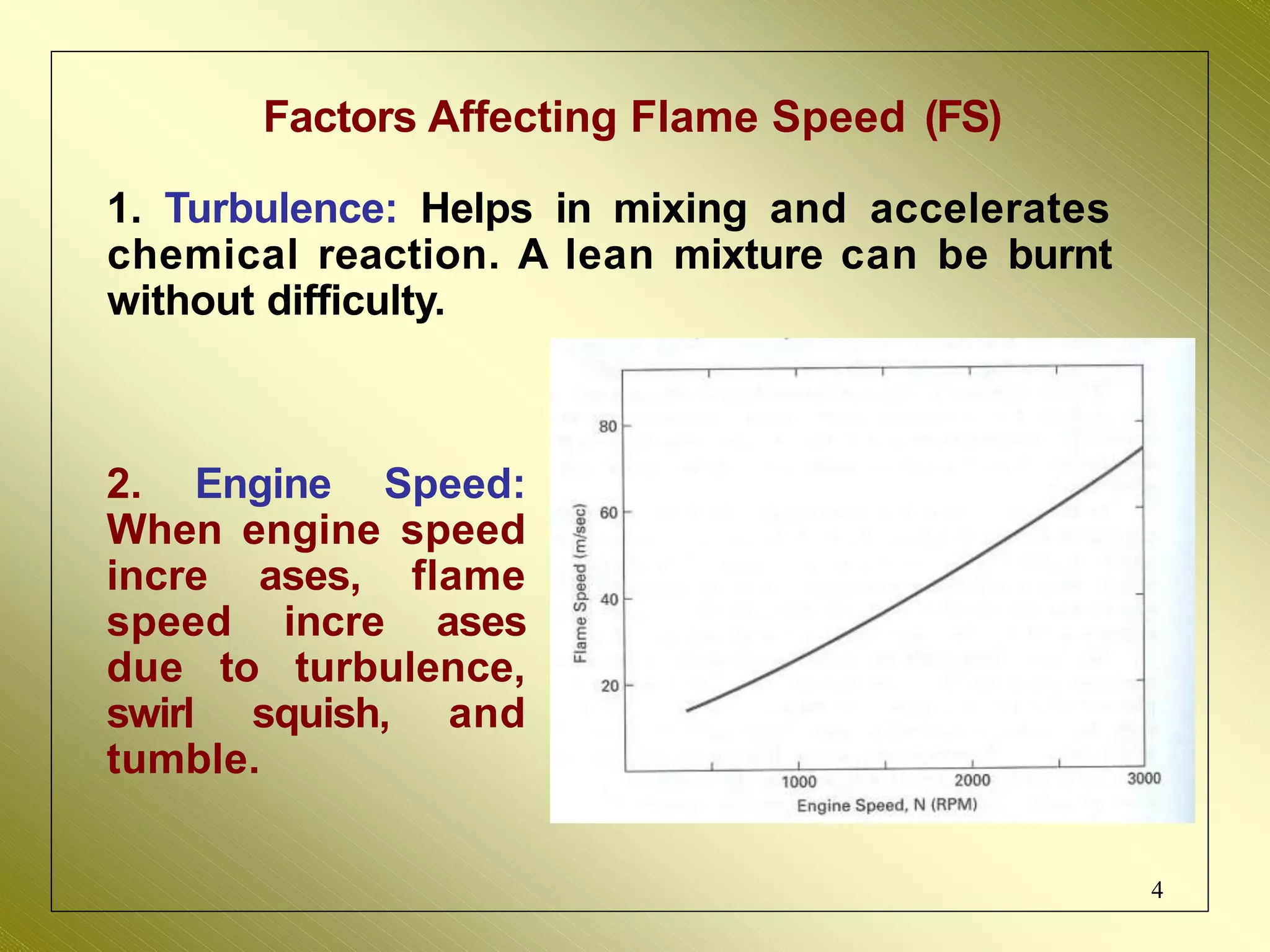

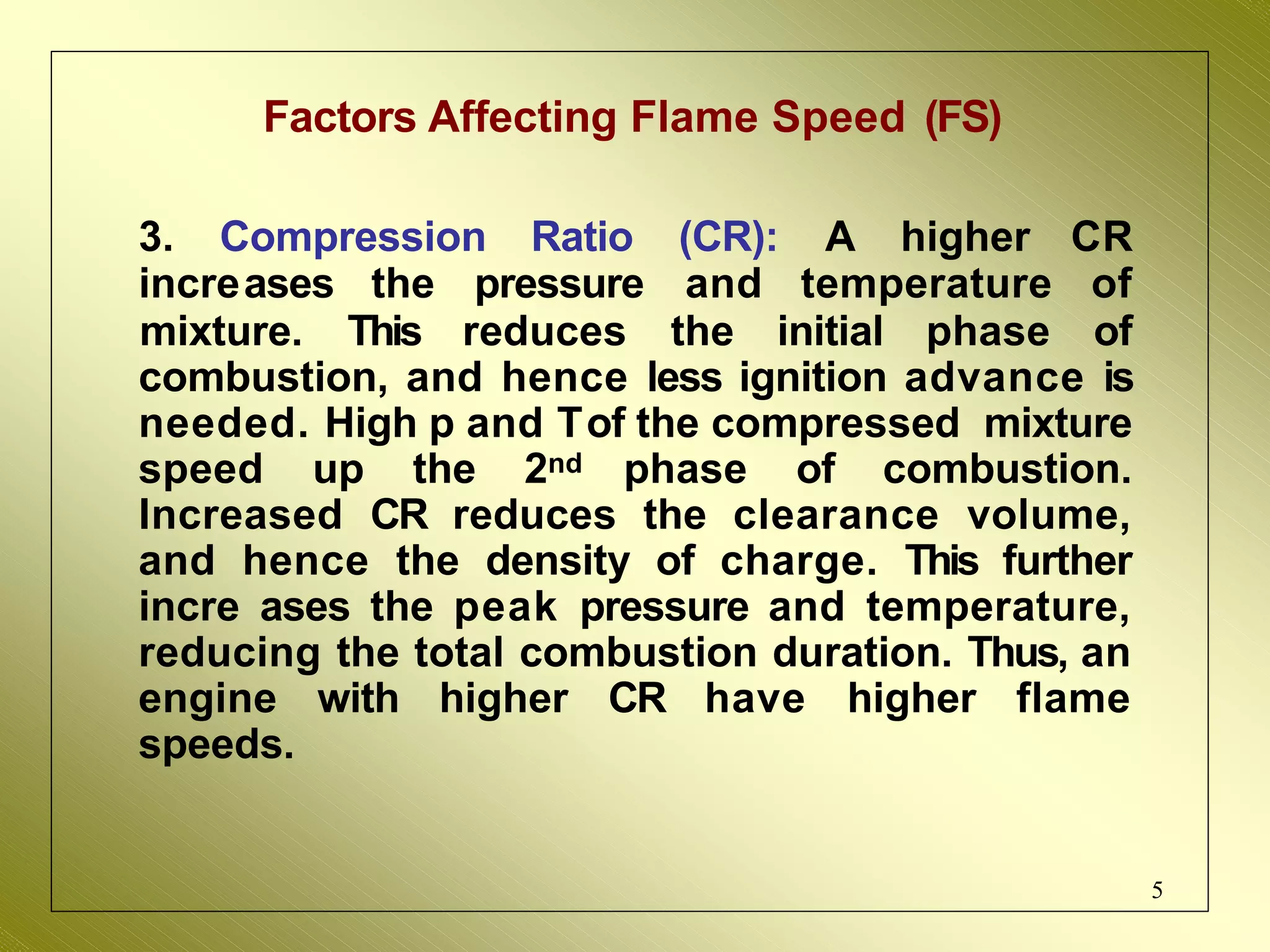

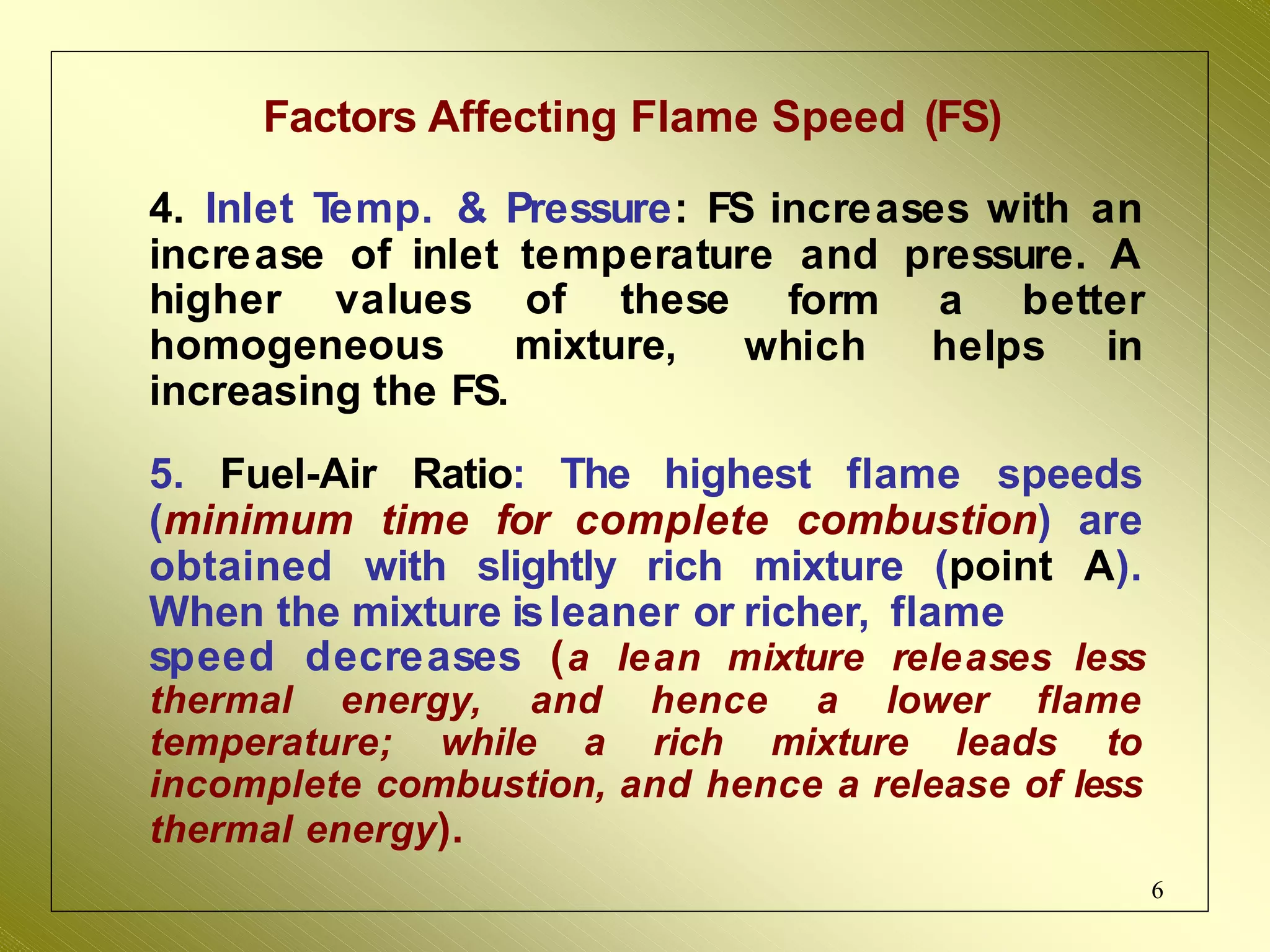

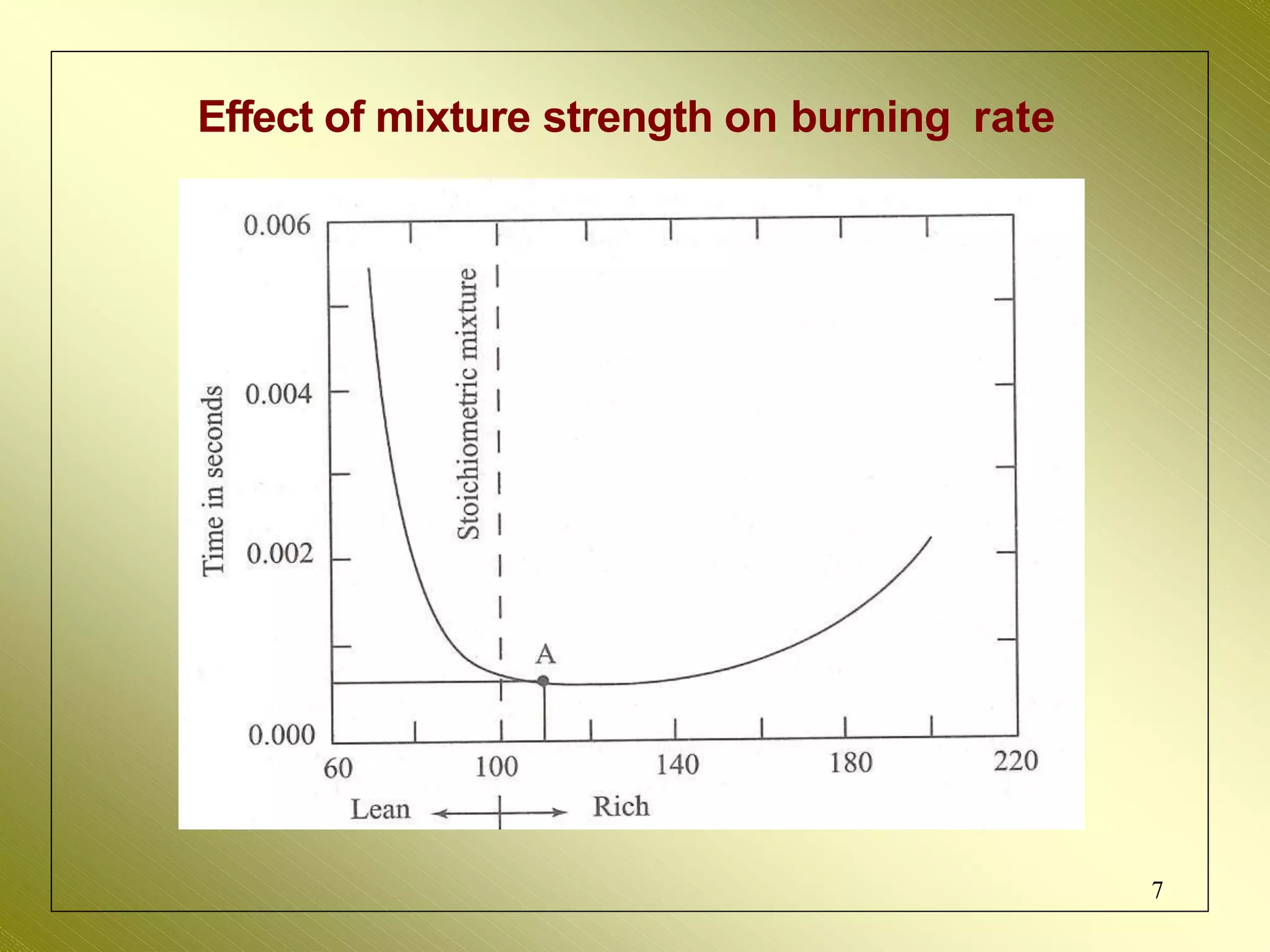

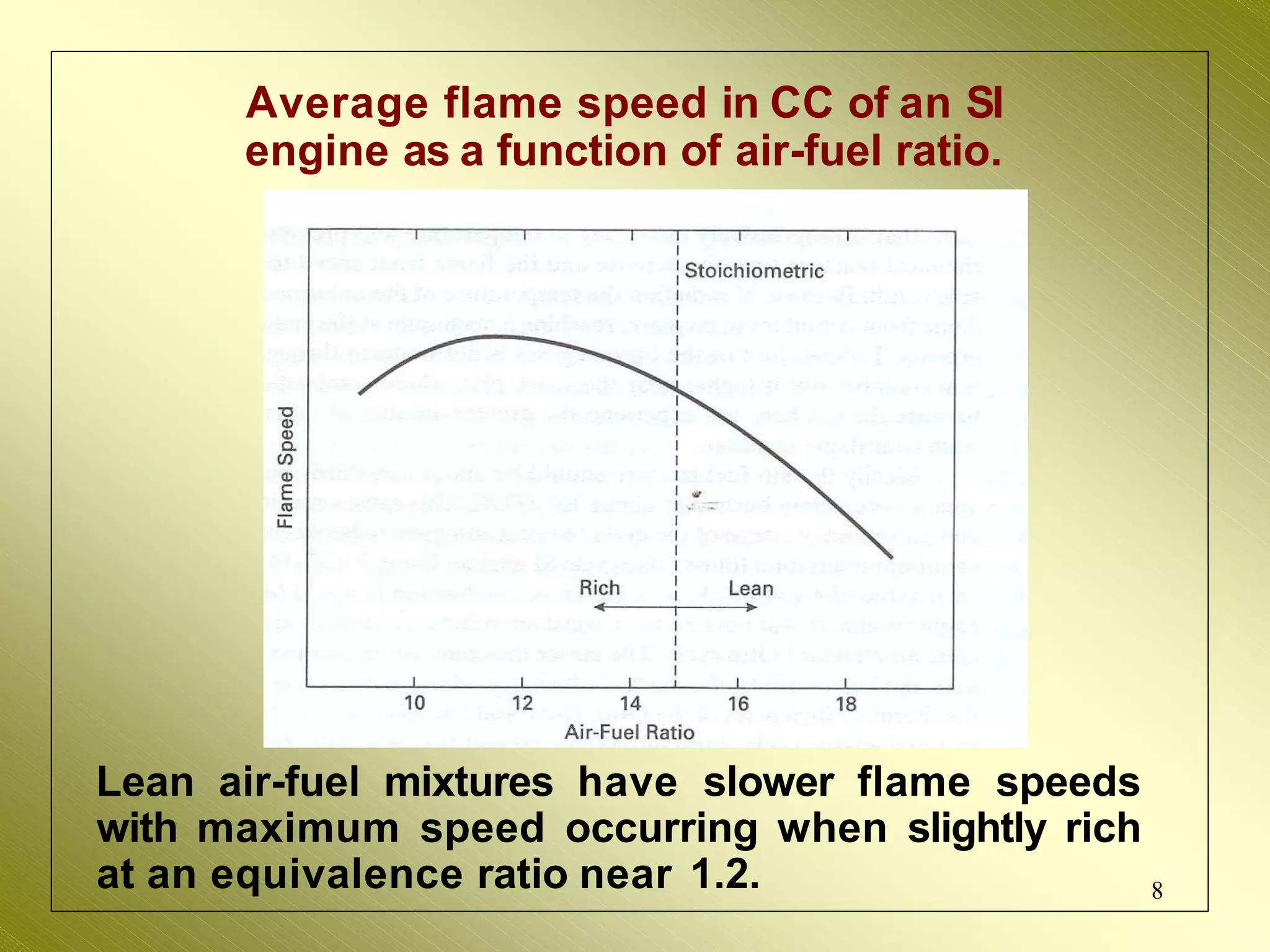

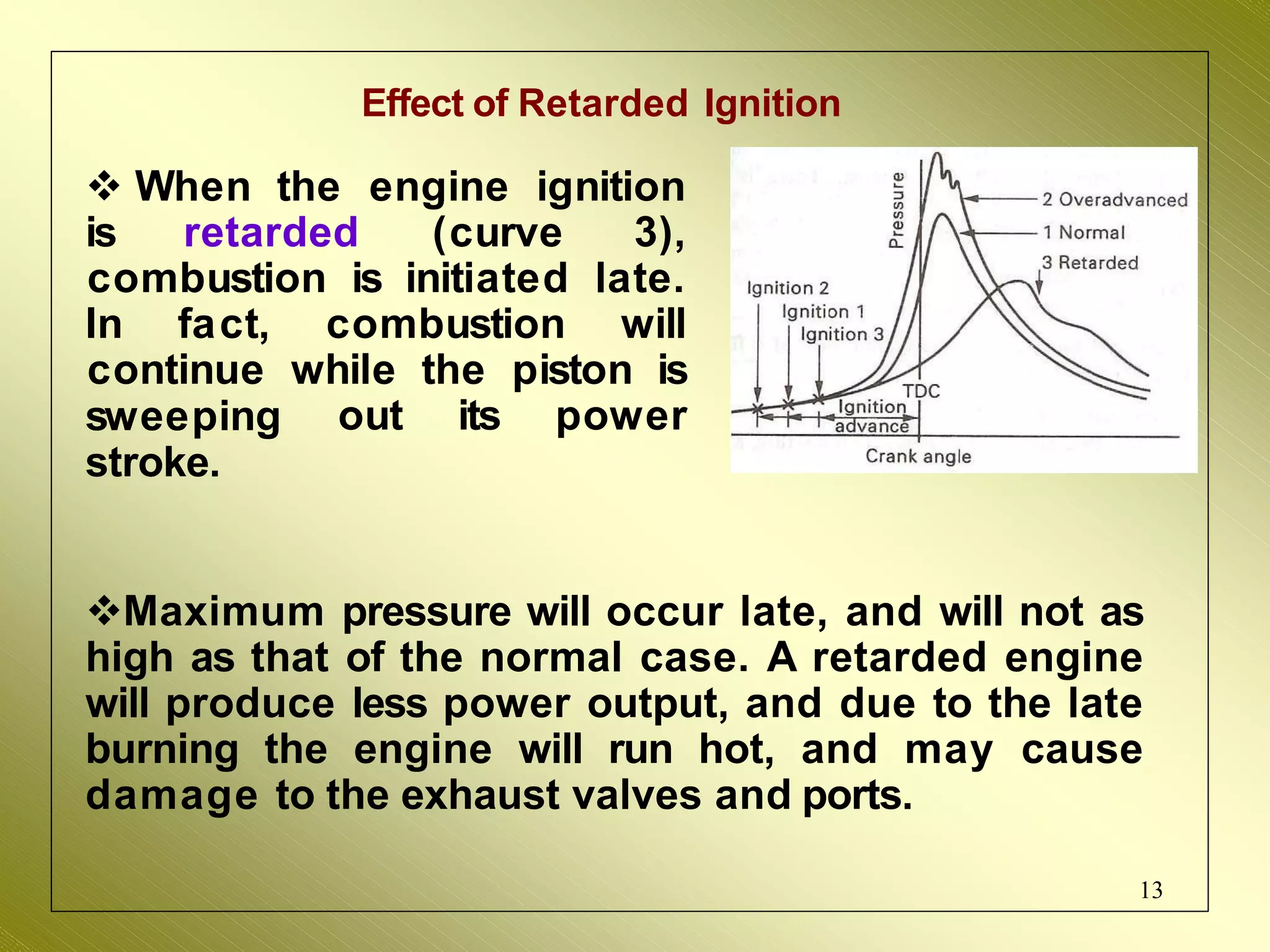

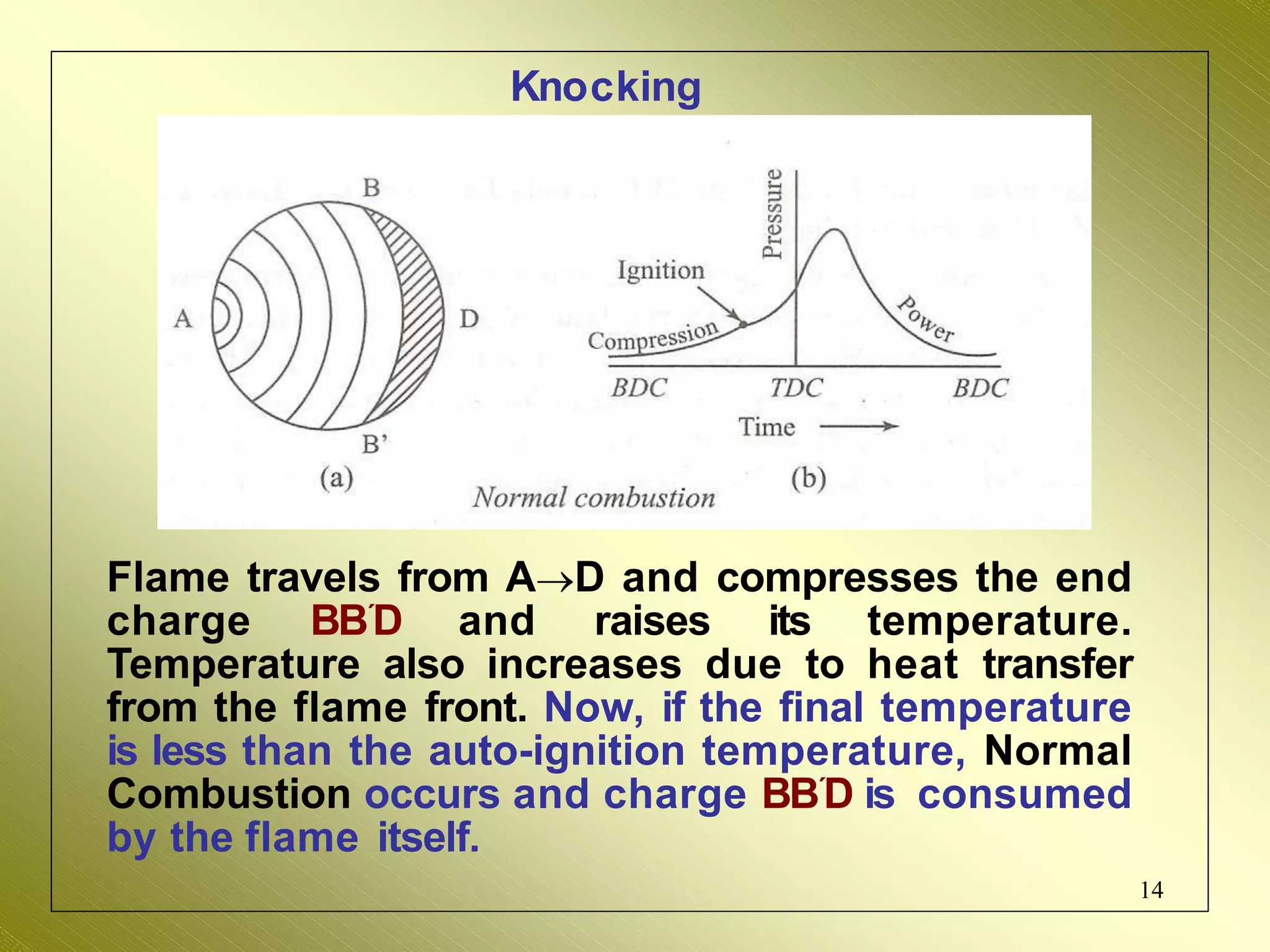

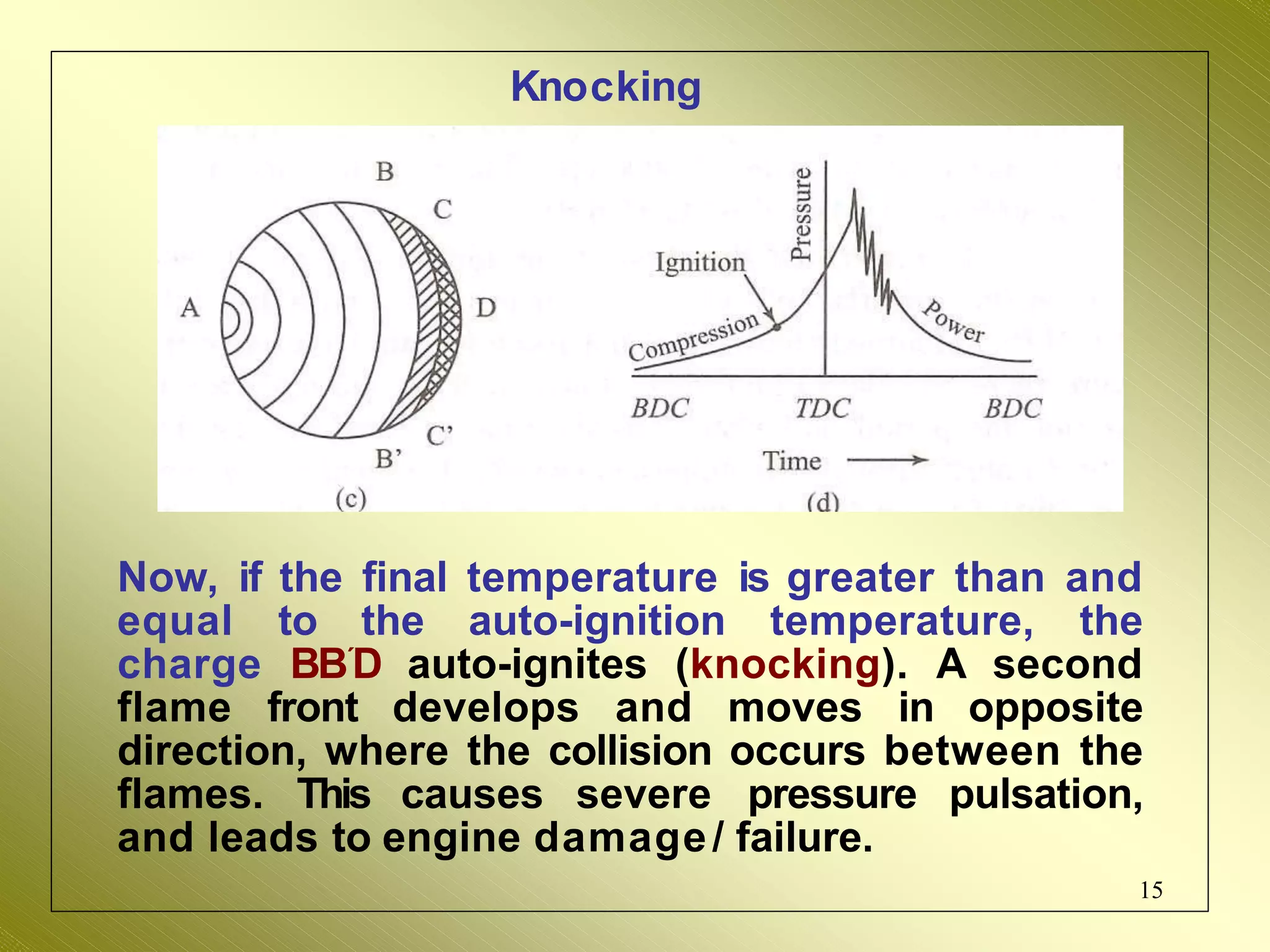

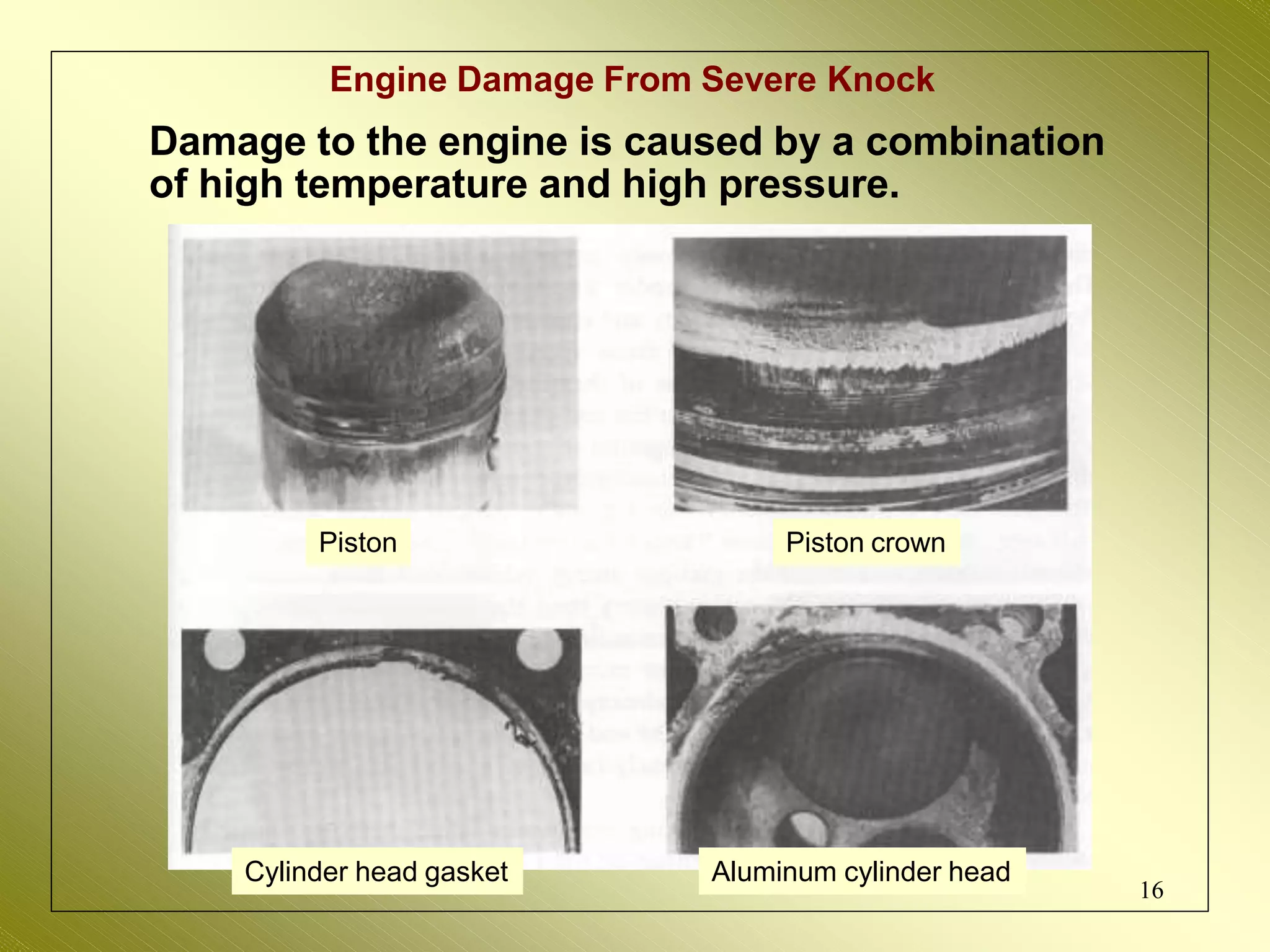

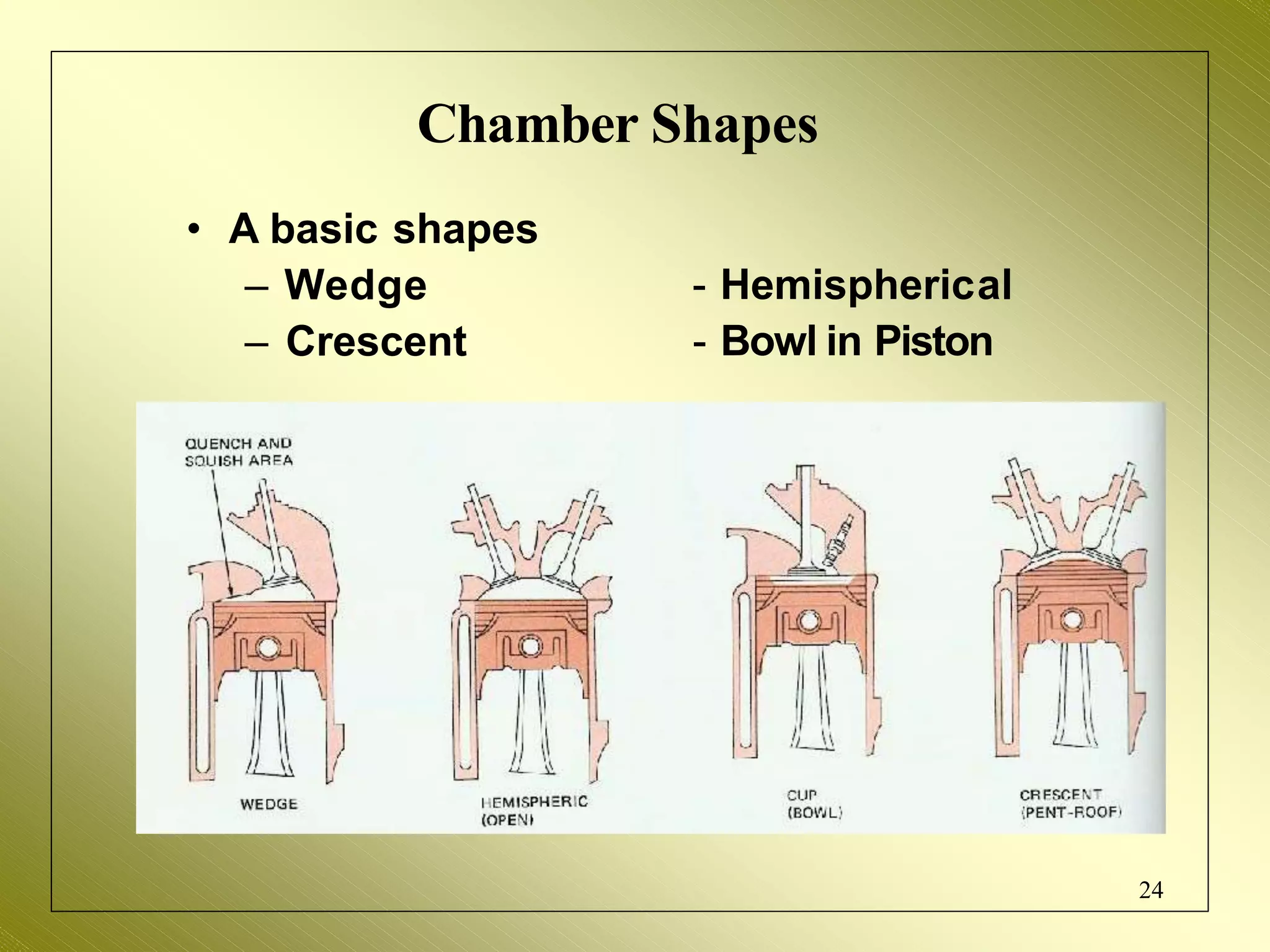

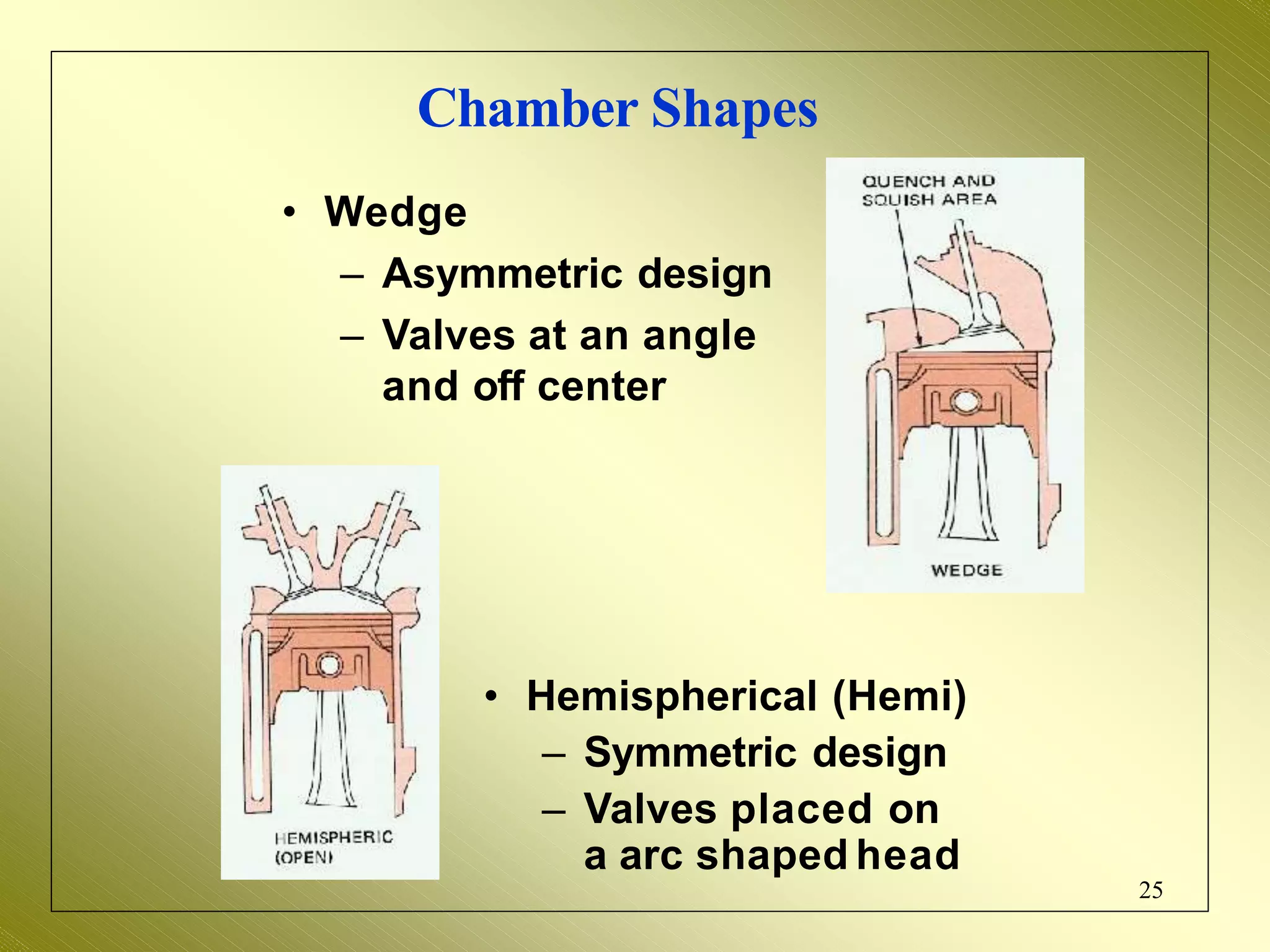

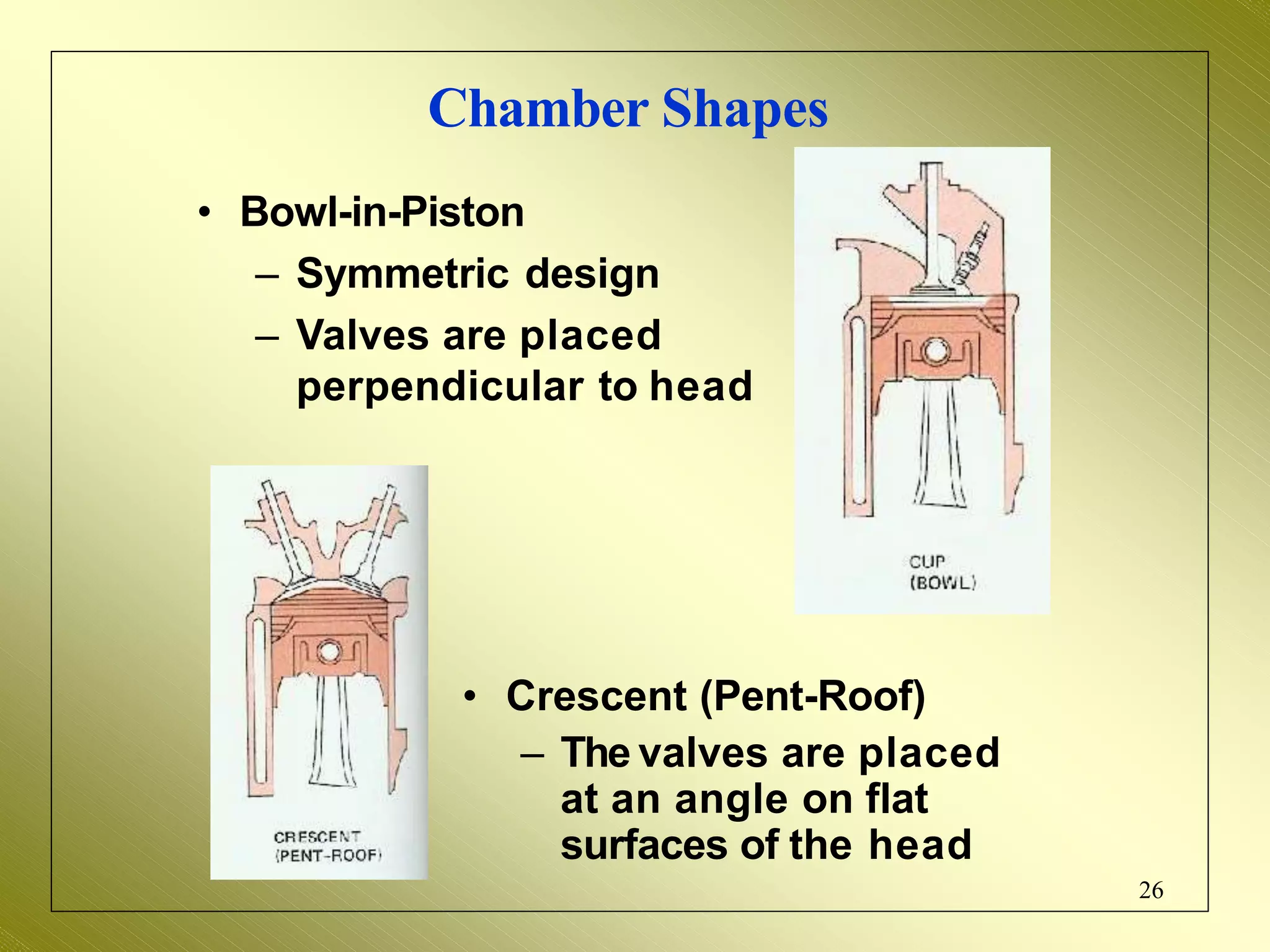

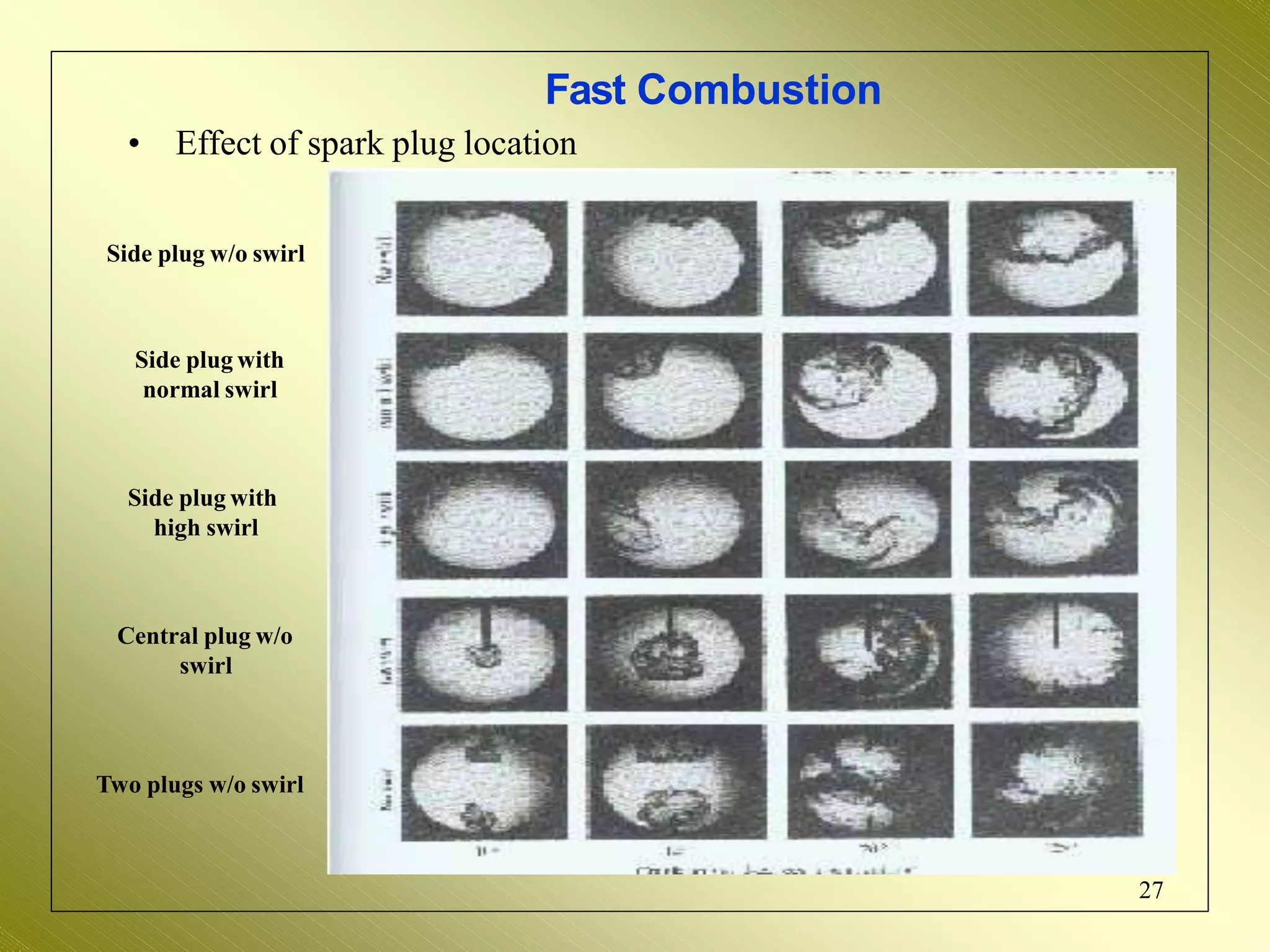

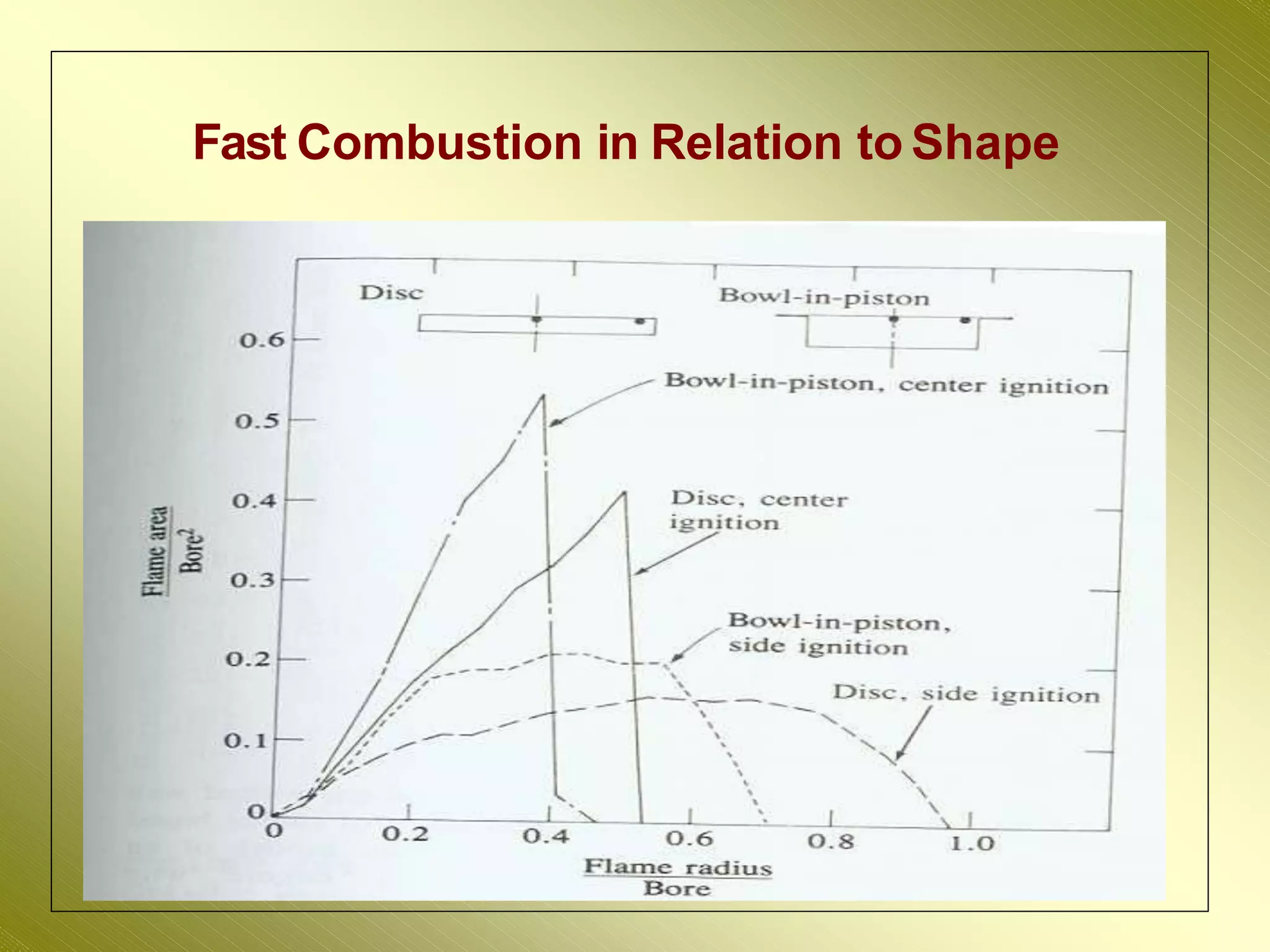

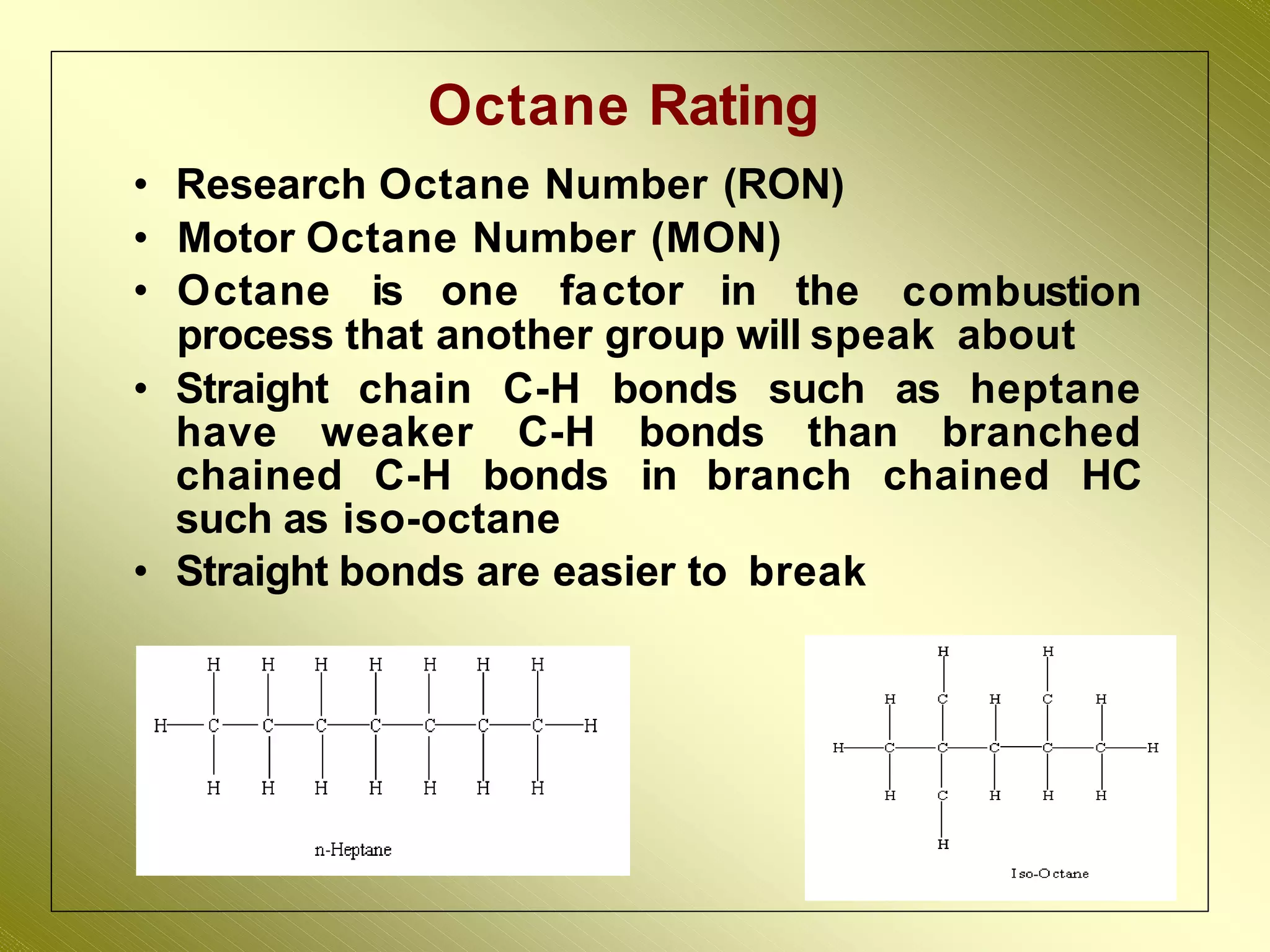

The document discusses factors that affect flame speed in internal combustion engines, including turbulence, engine speed, compression ratio, inlet temperature and pressure, and fuel-air ratio. It also covers abnormal combustion such as knocking, factors influencing knocking like density, time, and fuel composition, combustion chamber designs and their effects on flame speed and knocking, and definitions of octane number and types of knocking. The optimal combustion chamber design has a central spark plug location, minimum heat transfer, low octane requirement, and high turbulence for fast, consistent combustion.