This document discusses steam turbines. It begins by outlining the session objectives which are to classify steam turbines, discuss compounding of steam turbines, and cover forces, work done and efficiency. It then provides information on steam properties, the steam power plant process, types of steam turbines including impulse and reaction turbines, and losses that occur in steam turbines. It also discusses velocity triangles used to understand flow in turbine blades.

![PEMP

RMD 2501

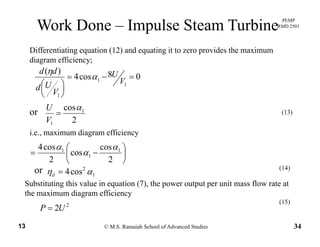

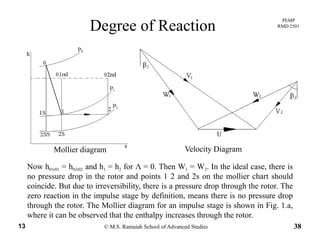

Degree of Reaction

( )

( )

21

hh

hh −

=Λ

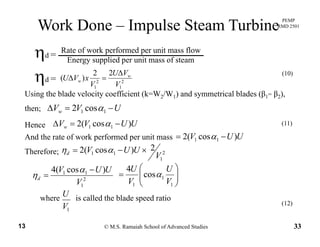

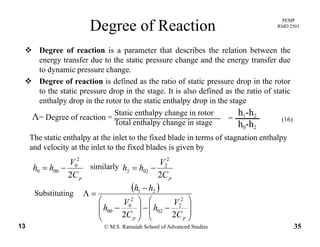

But for a normal stage, V0 = V2 and since h00 = h01 in the nozzle, then;

(17)

( )0201 hh −

We know that (h01 – h02) = ( ) ( ) 0

2

2

2

2

1

21 =

−

+− ww VV

hh

Substituting for (h h ) in equation (17)Substituting for (h1- h2) in equation (17),

( )

( )[ ]

2

1

2

2

2 hh

VV ww −

=Λ

( )

( )[ ]

2

1

2

2

2

ww

VVU

VV

−

−

=

(18)

( )[ ]02012 hh − ( )[ ]212 ww VVU −

Assuming the axial velocity is constant through out the stage, then

( )VV − 22

(18)

( )

( )[ ]UVVUU

VV

ww

ww

−++

−

=Λ

21

12

2

( )( )VVVV +−

© M.S. Ramaiah School of Advanced Studies13 36

( )( )

( )[ ]21

1212

2 ww

wwww

VVU

VVVV

+

+−

=Λ (19)](https://image.slidesharecdn.com/steamturbines-191229120443/85/Steam-turbines-36-320.jpg)

![PEMP

RMD 2501

F t 1

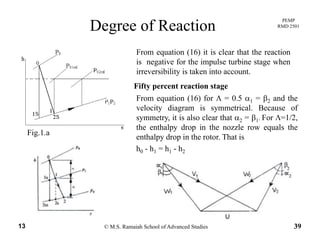

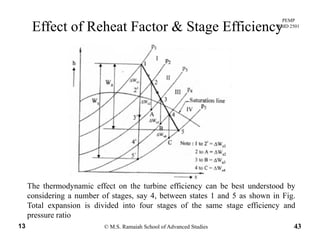

Effect of Reheat Factor & Stage Efficiency

For stage 1

111

1

1

'

21

21

1

1

1.,. ssa

s

a

s

a

s WWor

W

W

hh

hh

W

W

ei Δ=Δ

Δ

=

−

−

== ηη

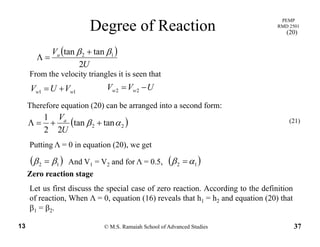

[ ][ ]44332211 ssssssssaa WWWWWW Δ+Δ+Δ+ΔΣ=ΣΔ=Δ∴ ηηηη

For same stage efficiency in each stage 4321 ssss ηηηη ===

[ ][ ] sssssssa WWWWWW ΣΔ=Δ+Δ+Δ+ΔΣ= ηη 4321 (23)

From equation (22) and (23),

s

s

ss

W

W

WW

ΣΔ

=∴

ΣΔ=

ηη

ηη

0

00

(24)

s

s

W

ηη0

The slope of constant pressure lines on h-s plane is given by

T

h

⎟

⎞

⎜

⎛ ∂

© M.S. Ramaiah School of Advanced Studies13 45

T

s

h

p

=⎟

⎠

⎞

⎜

⎝

⎛

∂

∂](https://image.slidesharecdn.com/steamturbines-191229120443/85/Steam-turbines-45-320.jpg)

![PEMP

RMD 2501

Effect of Reheat Factor & Stage Efficiency

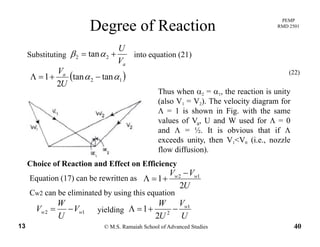

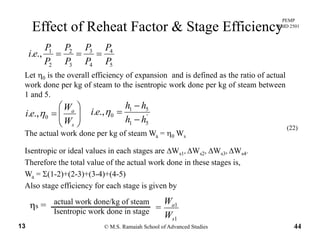

This shows that the constant pressure lines must diverge towards the right.

Therefore

.

F i I i b i h h h l i h

1>

ΣΔ

s

s

W

W

For expansion process. It is obvious that the enthalpy increases when we move

towards right along the constant pressure line. Hence the summation of ΔWs1

ΔWs1 etc., is more than the total isentropic enthalpy drop Ws

Th ti f ti f i t i th l d f i di id l t t th t t l

[ ] [ ])4()3()2()21( ''''

4321 −+−+−+−Σ

=

Δ+Δ+Δ+ΔΣ

=

cbaWWWW

RF ssss

The ratio of summation of isentropic enthalpy drop for individual stage to the total

isentropic enthalpy drop as a whole is called Reheat factor. Thus

)51( −W

RF

s

s

s

W

W

RF

ΣΔ

=

Therefore the overall efficiency of the expansion process

(25)

As

Therefore the overall efficiency of the expansion process,

RFstage ×=ηη0

(26)

1)/( >ΣΔ= ss WWRF

th ll ffi i f th t bi i t th th t ffi i i

© M.S. Ramaiah School of Advanced Studies13 46

the overall efficiency of the turbine η0 is greater than than stage efficiencies ηs

sei ηη >0.,. for turbines (27)](https://image.slidesharecdn.com/steamturbines-191229120443/85/Steam-turbines-46-320.jpg)