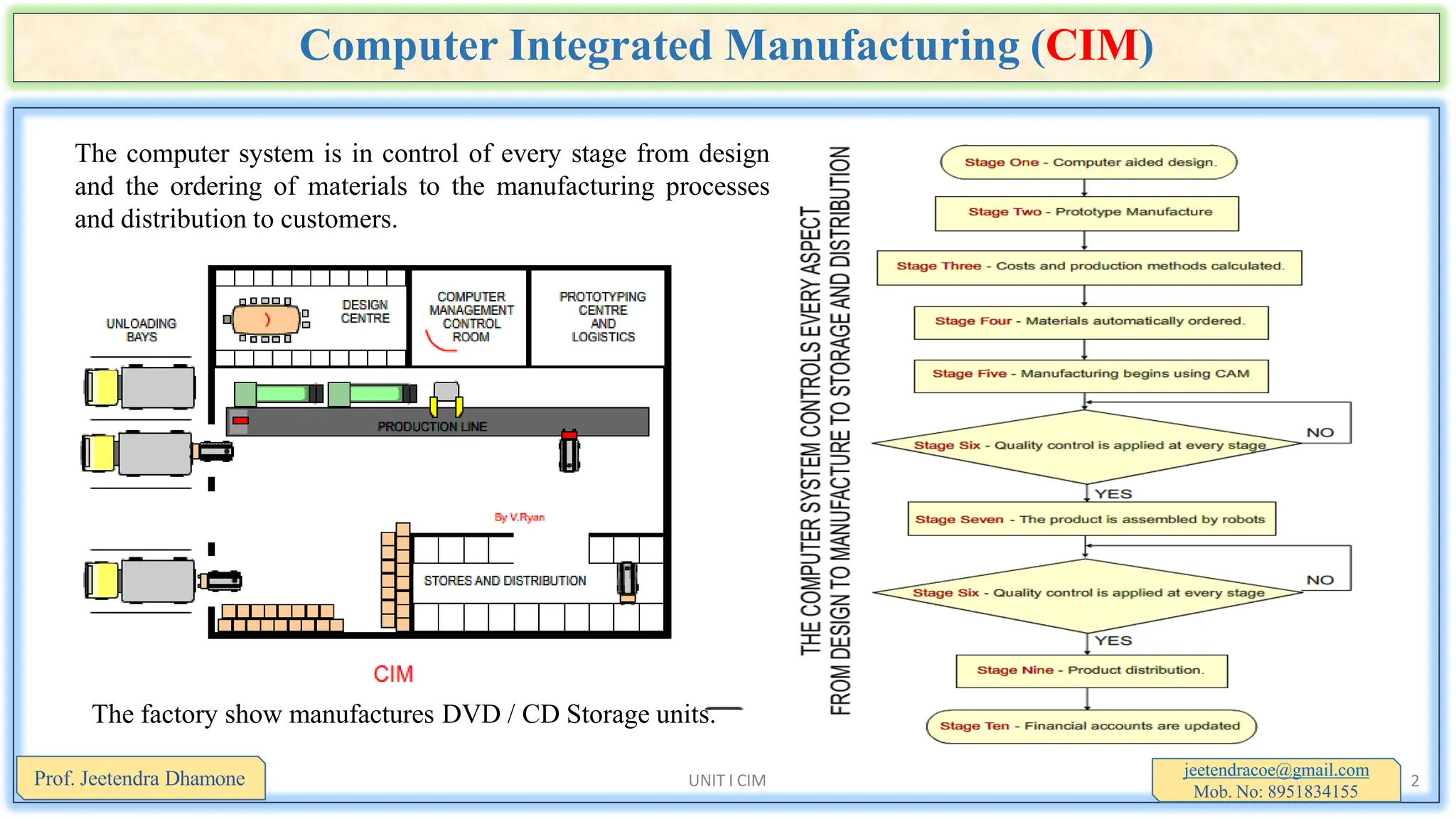

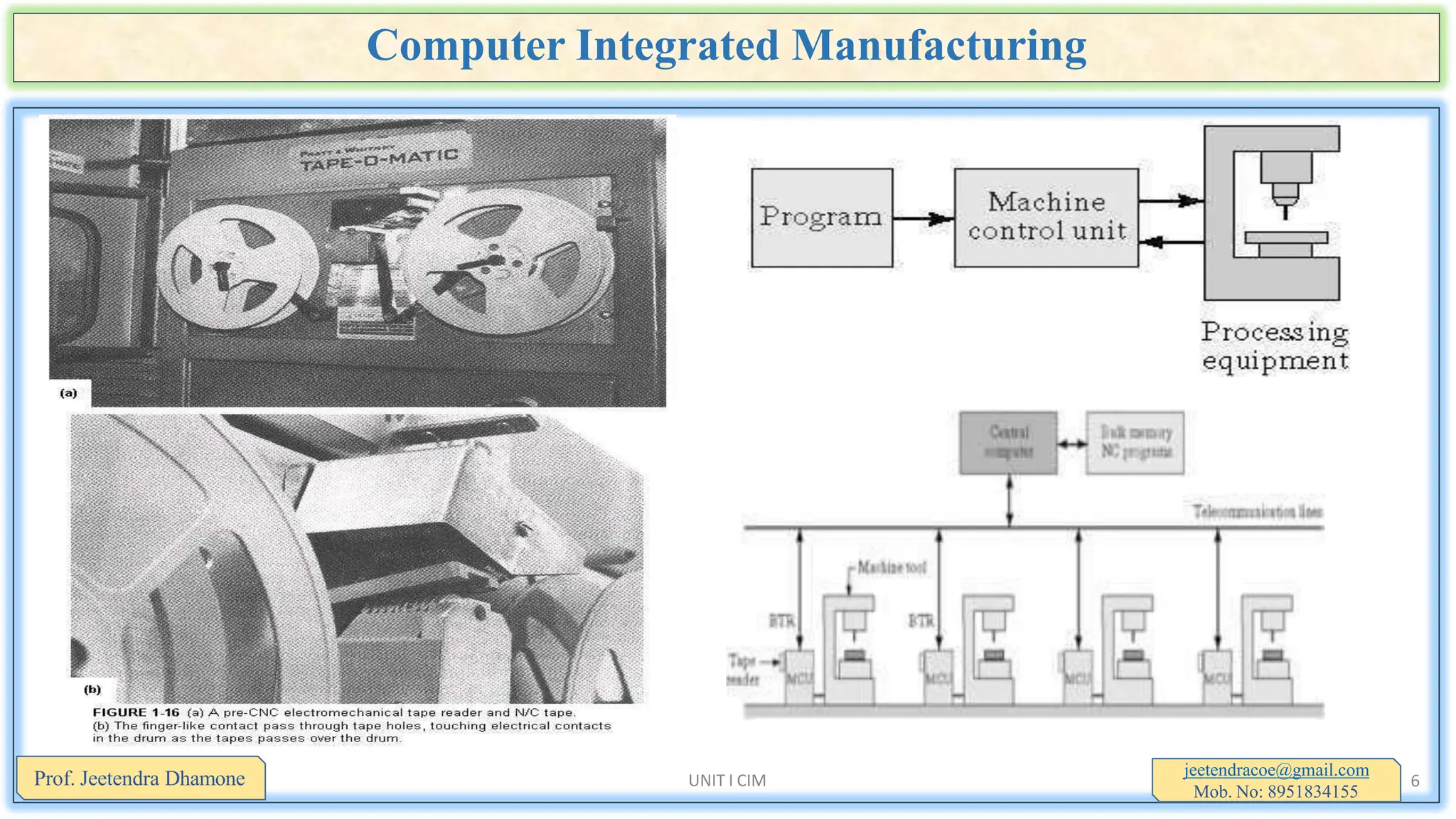

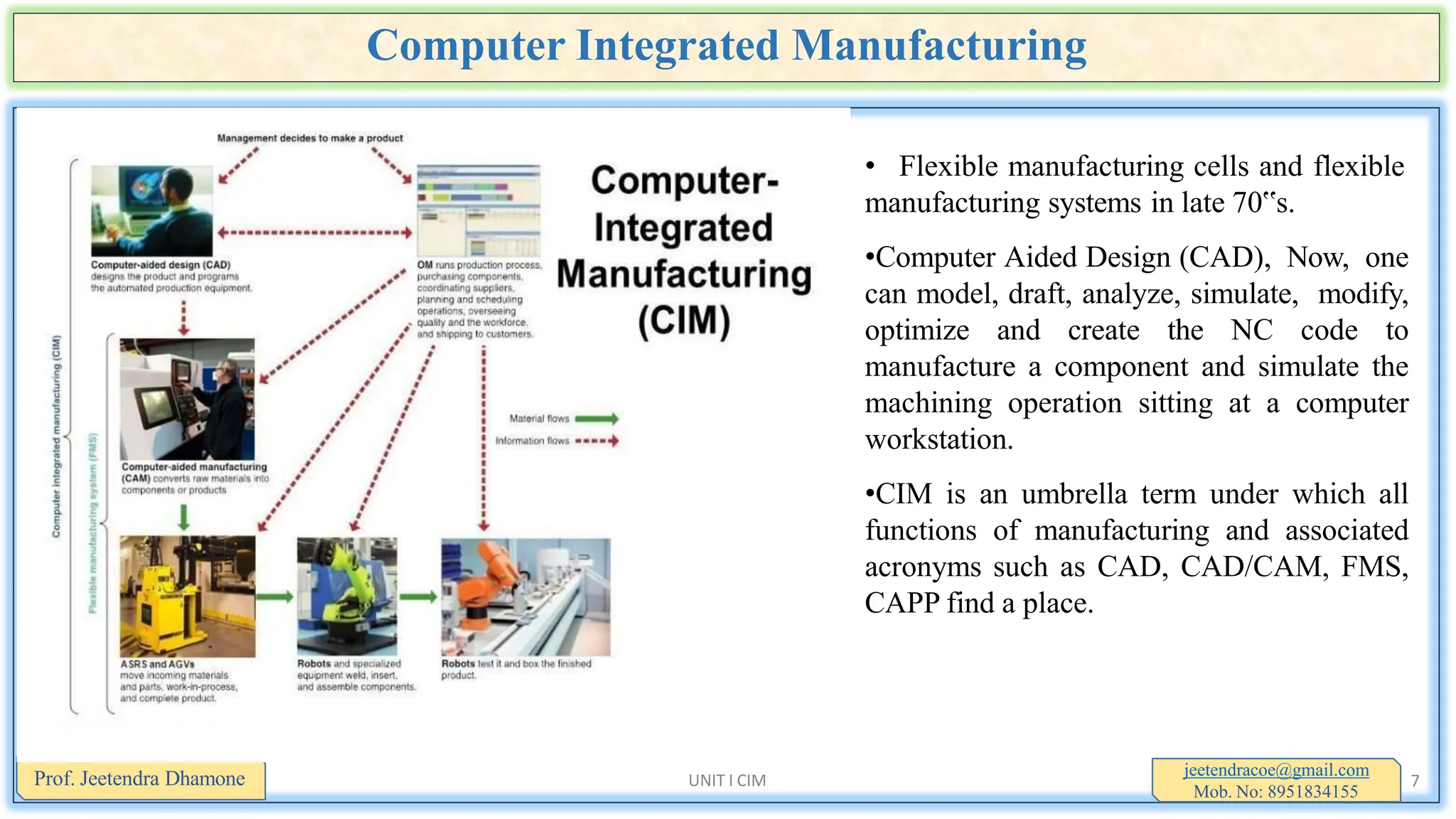

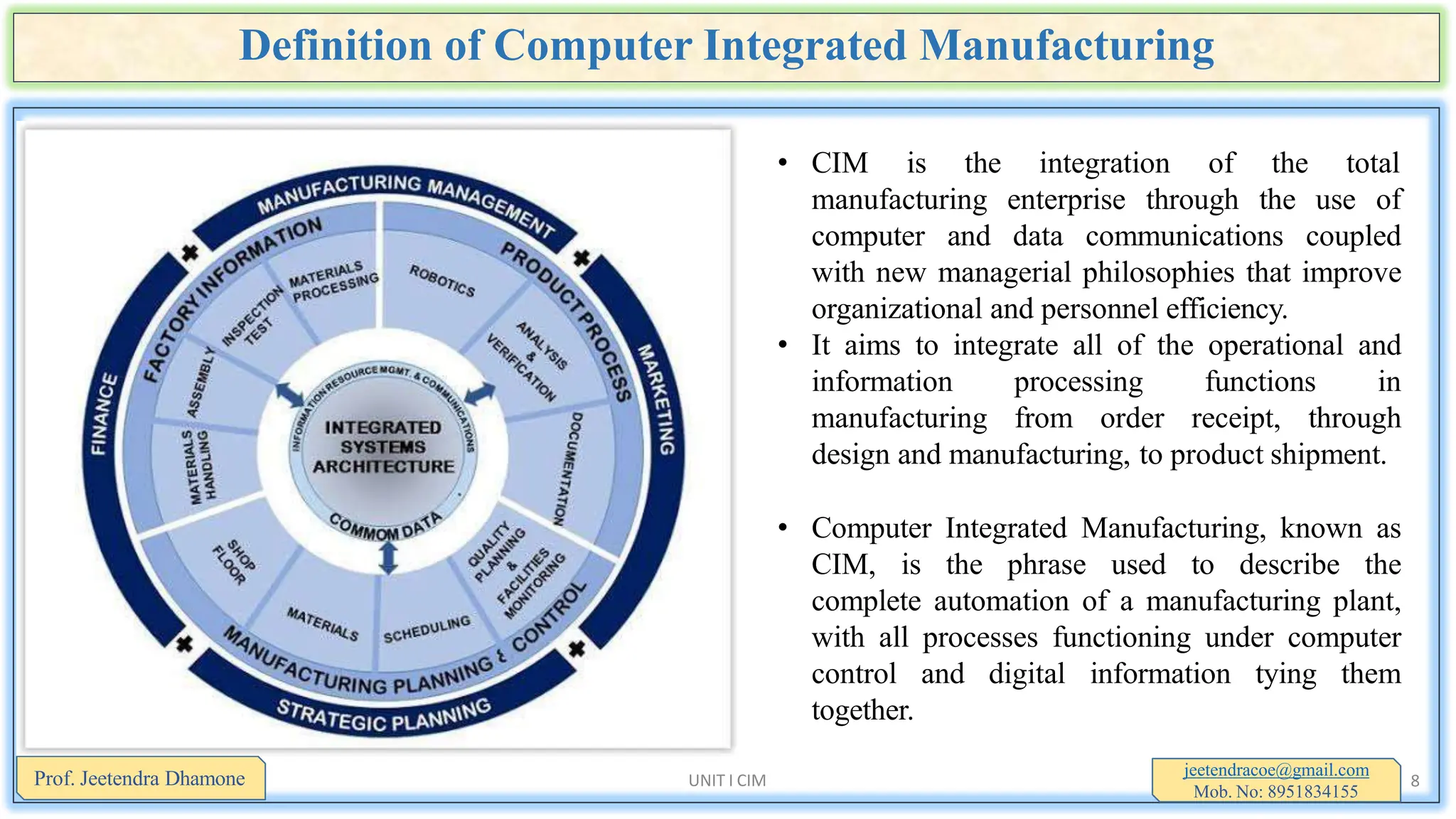

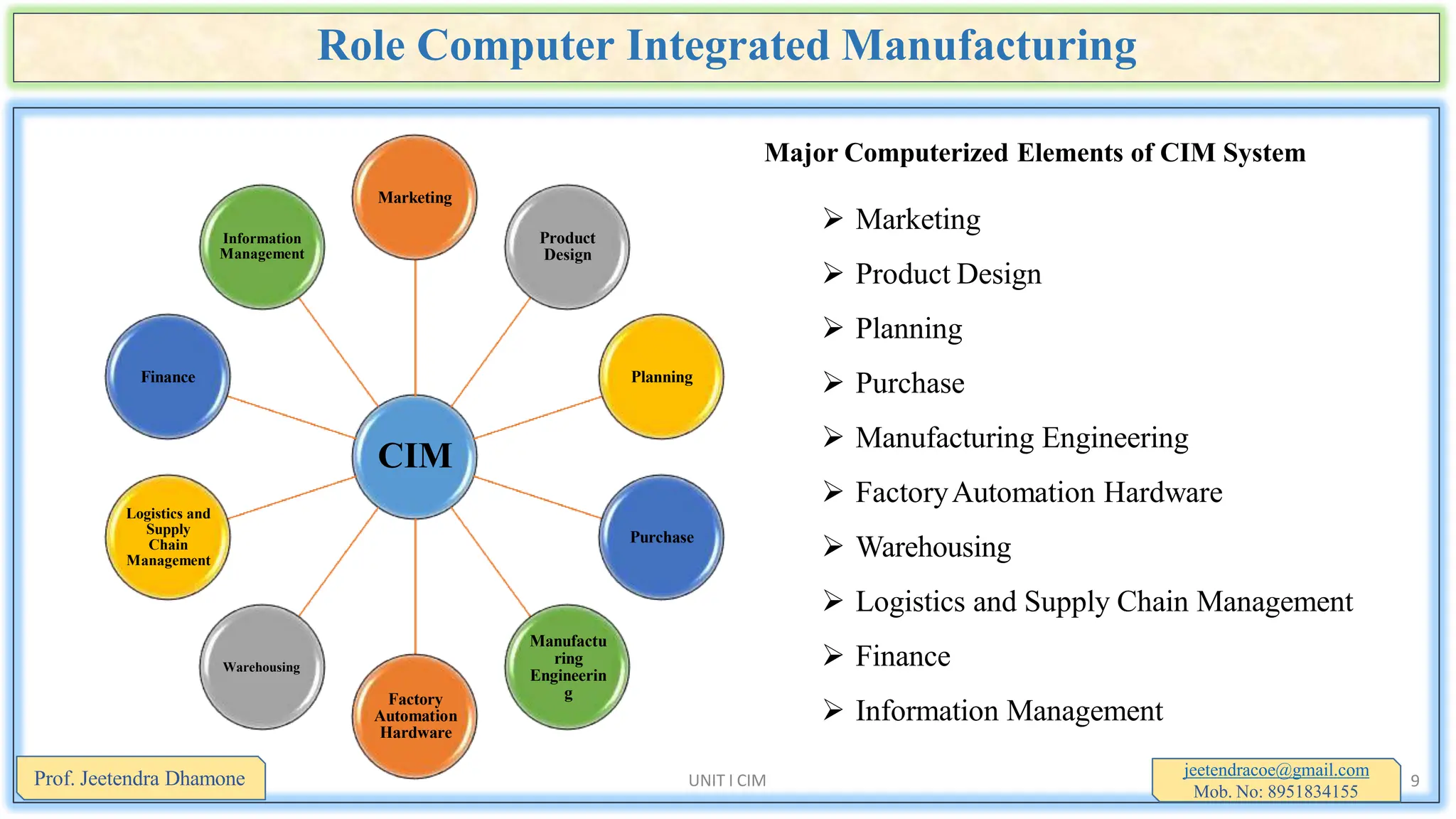

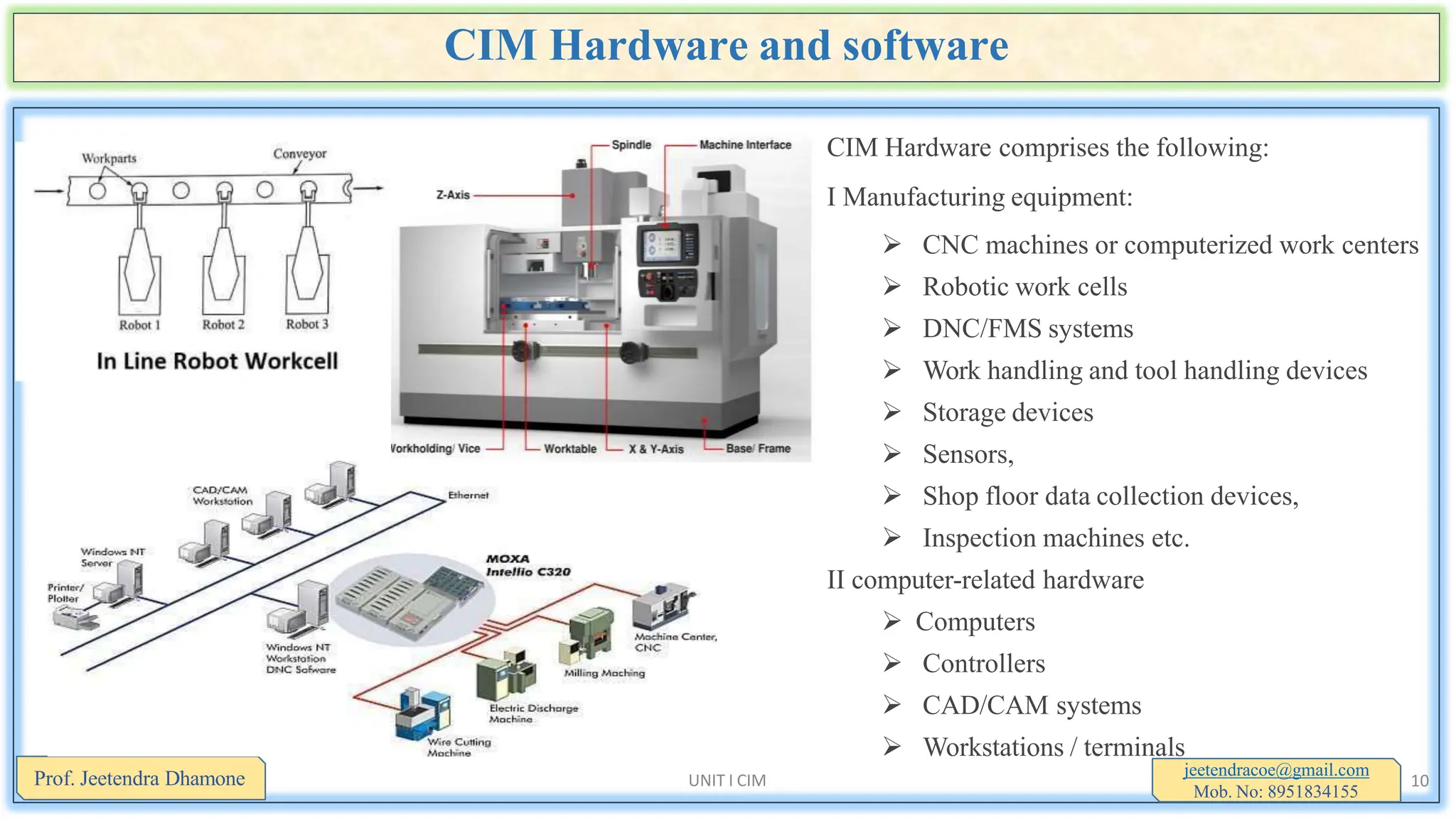

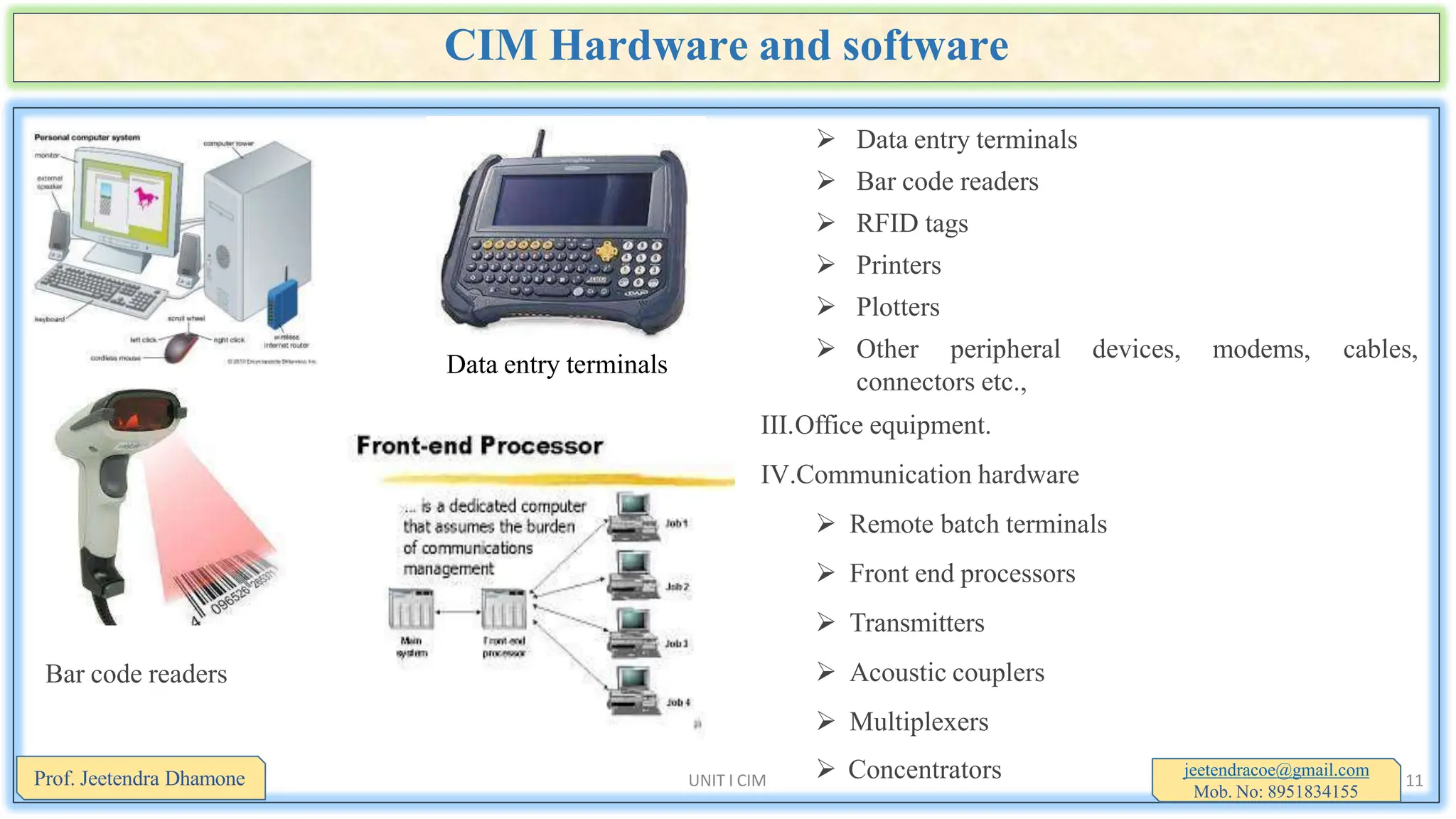

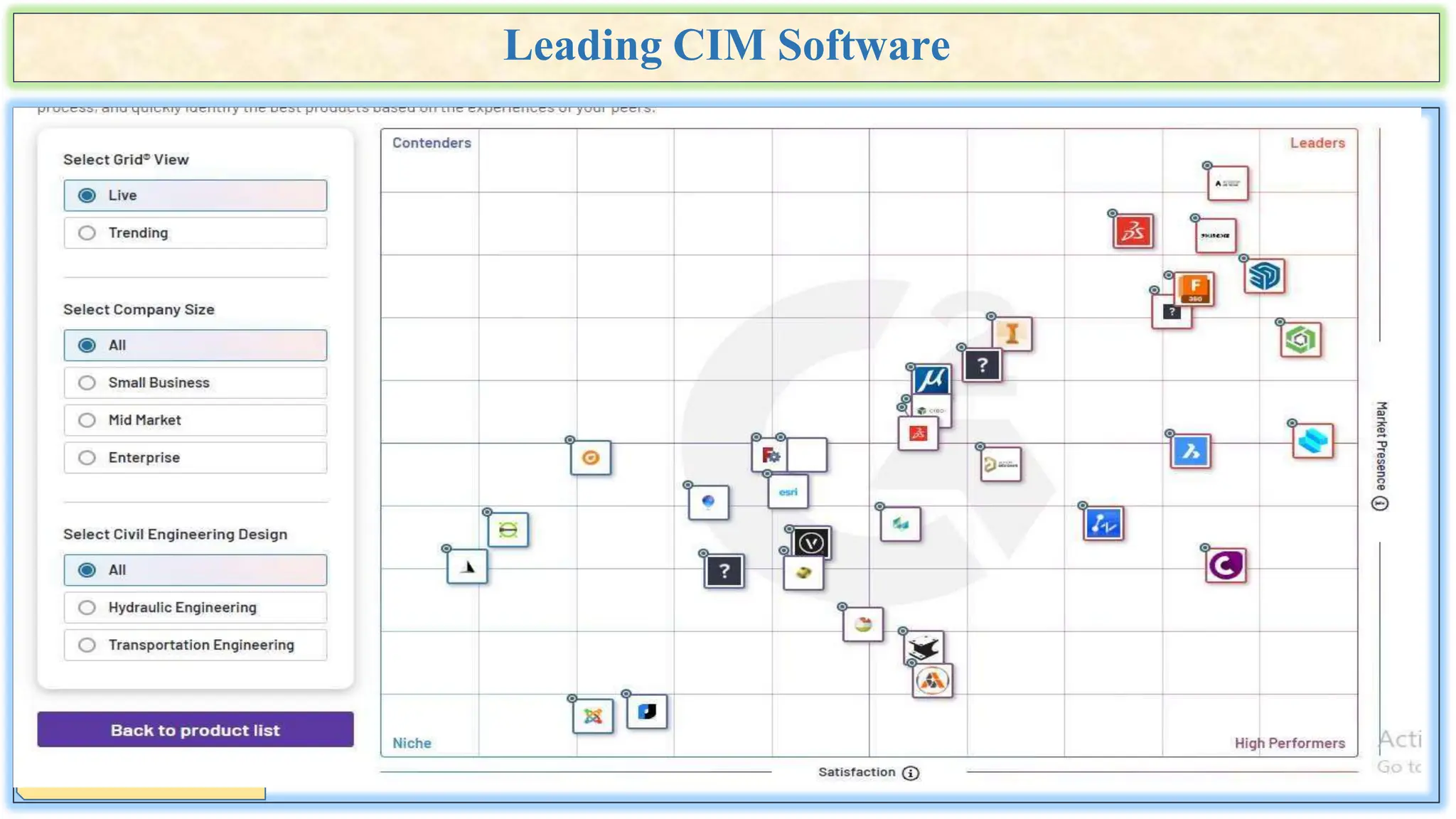

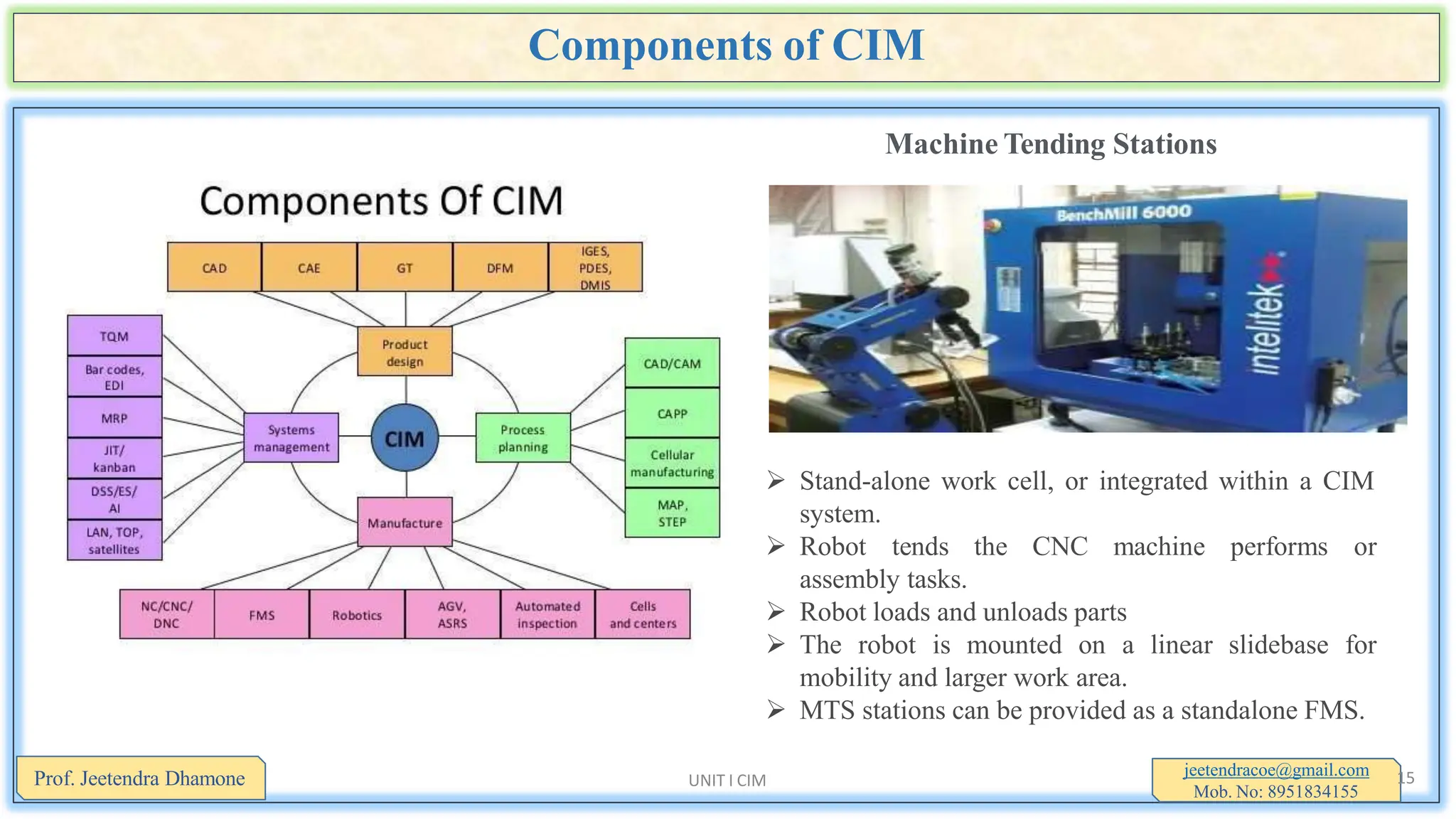

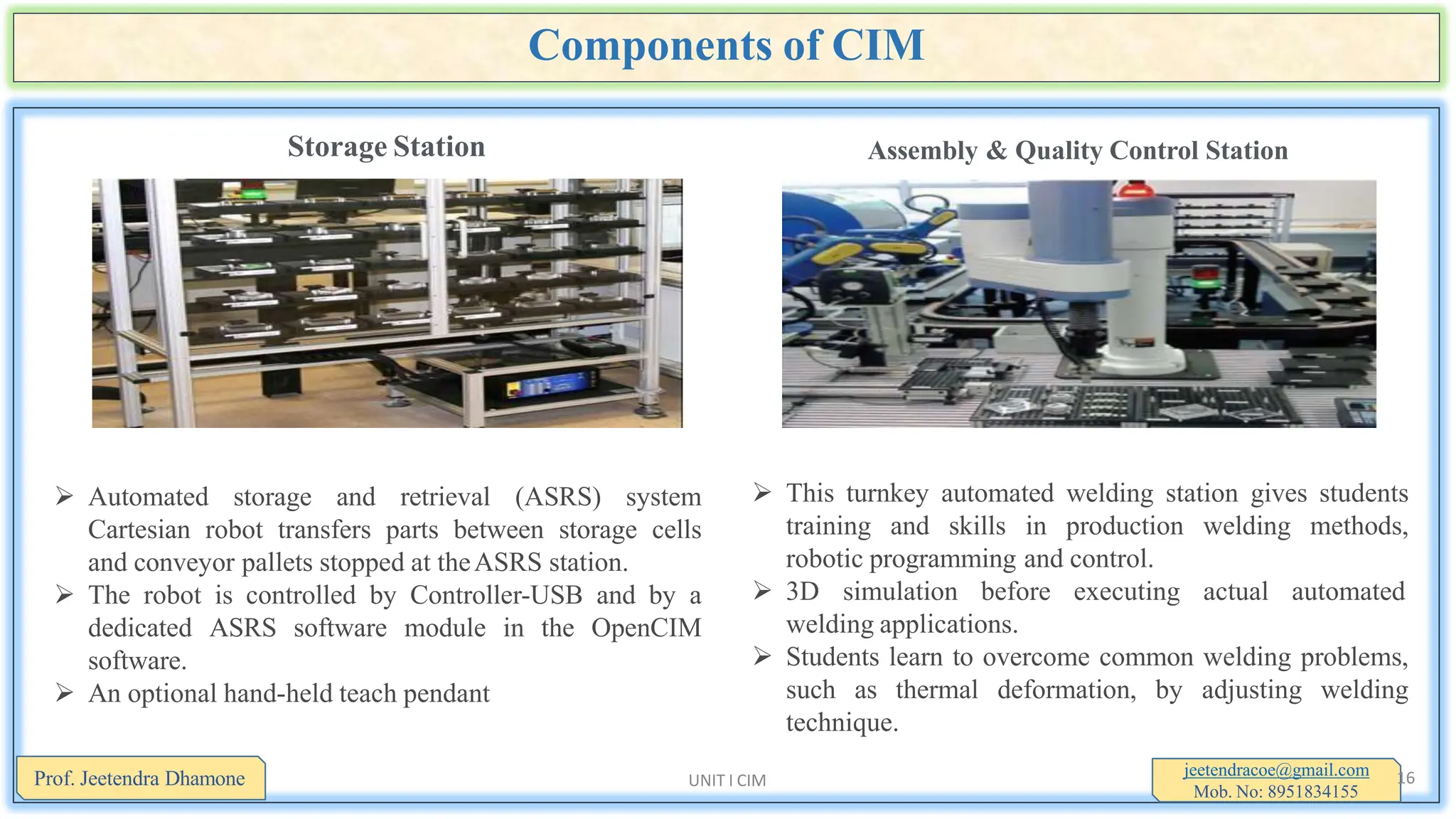

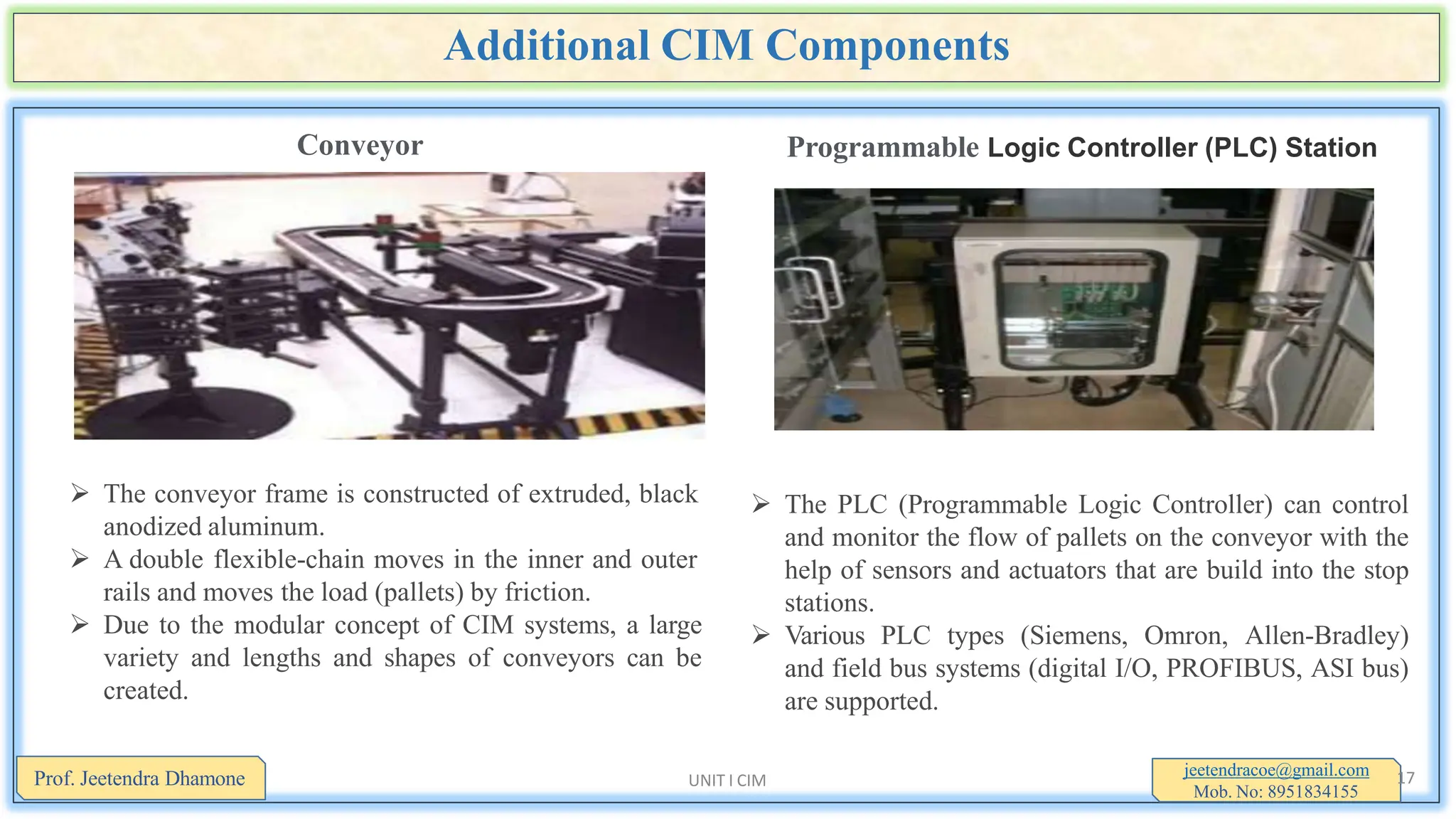

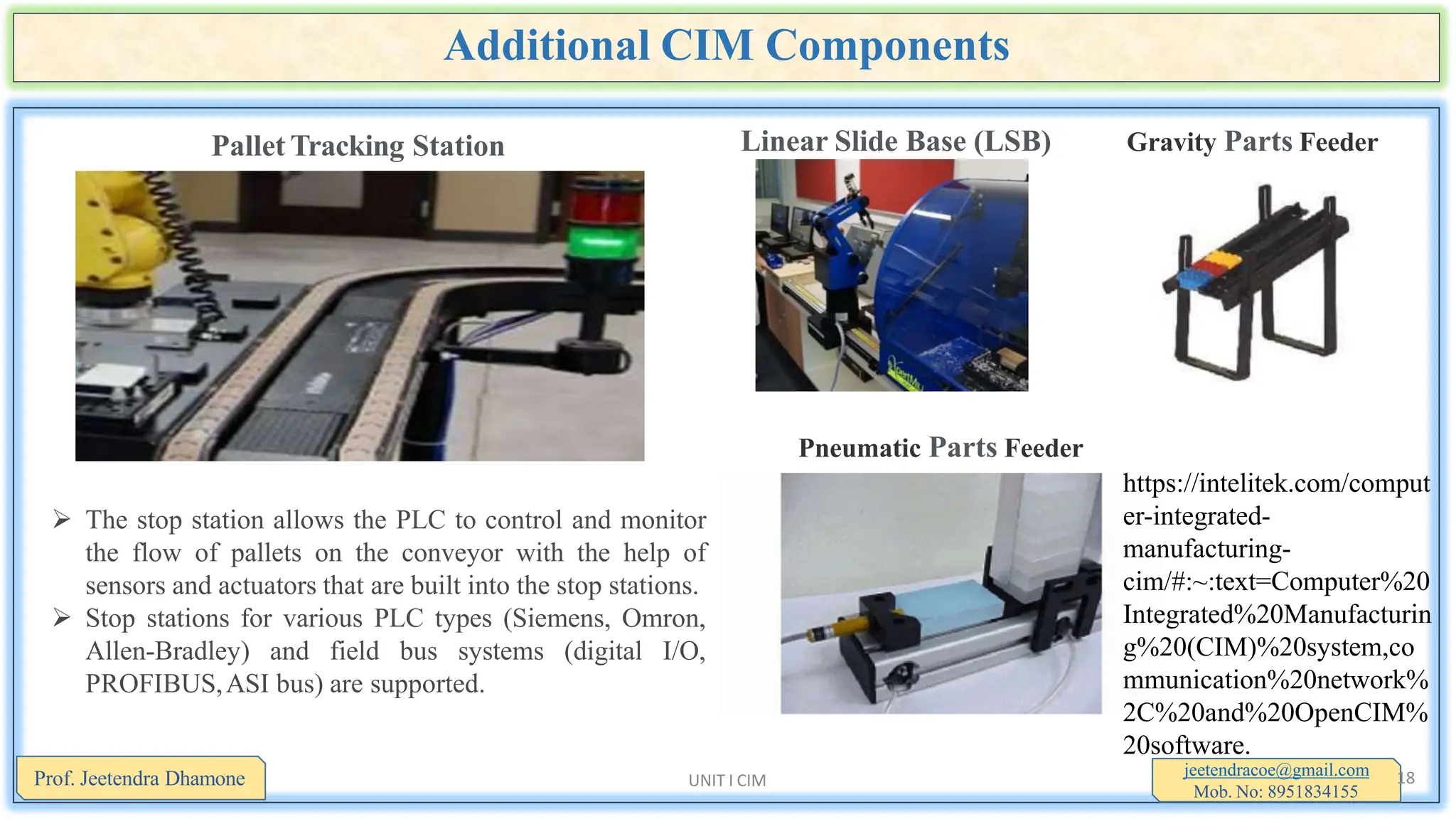

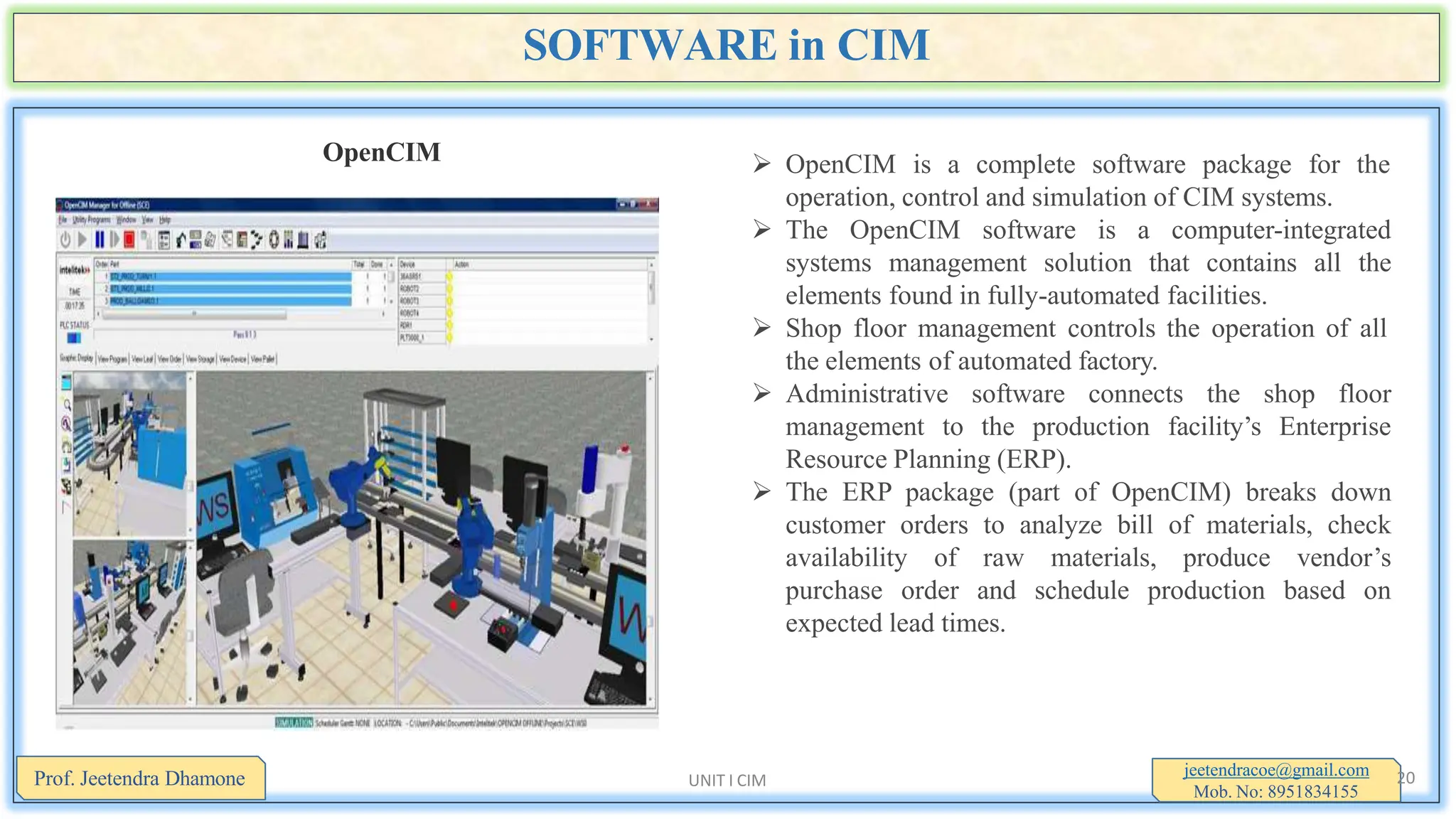

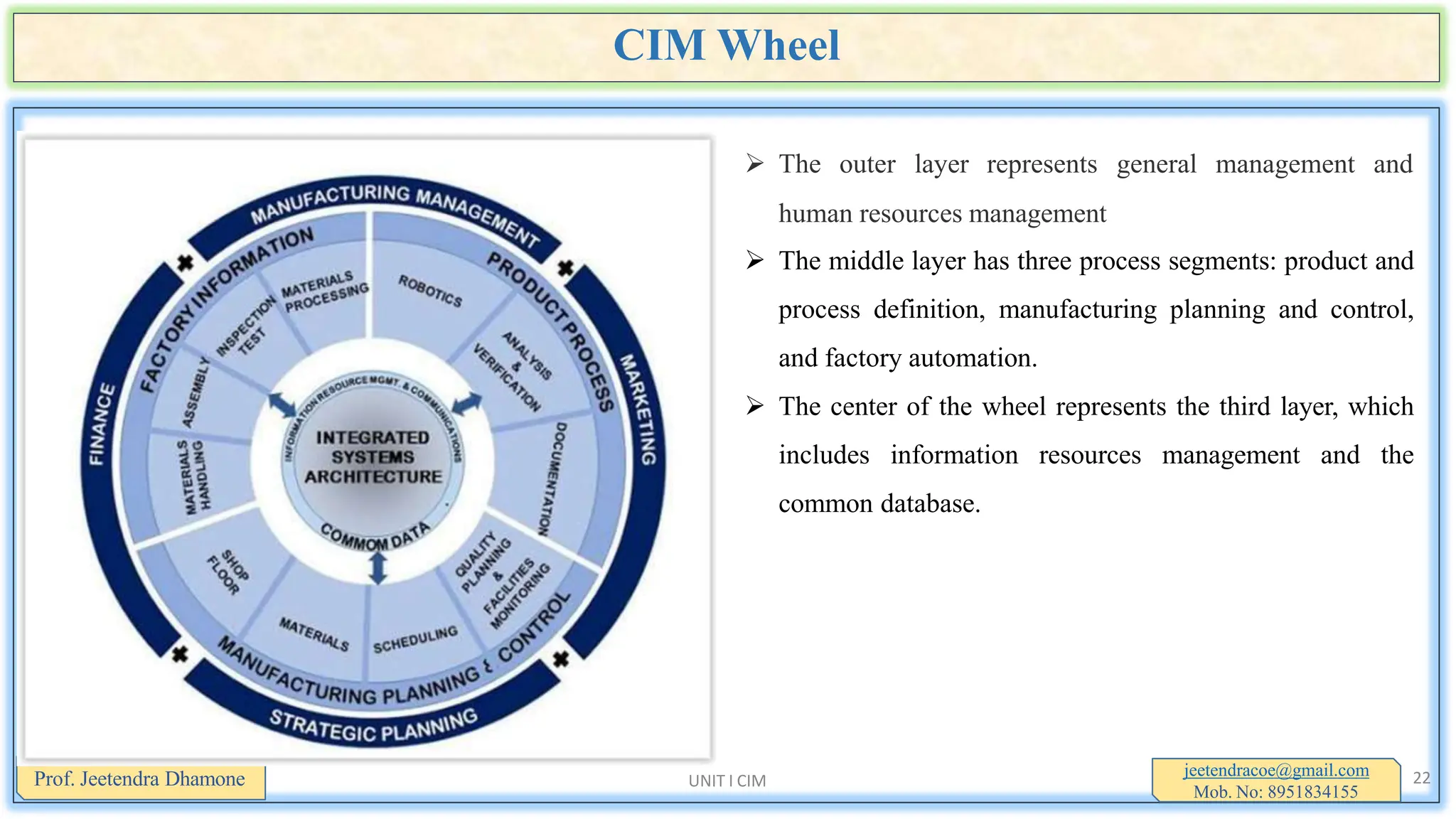

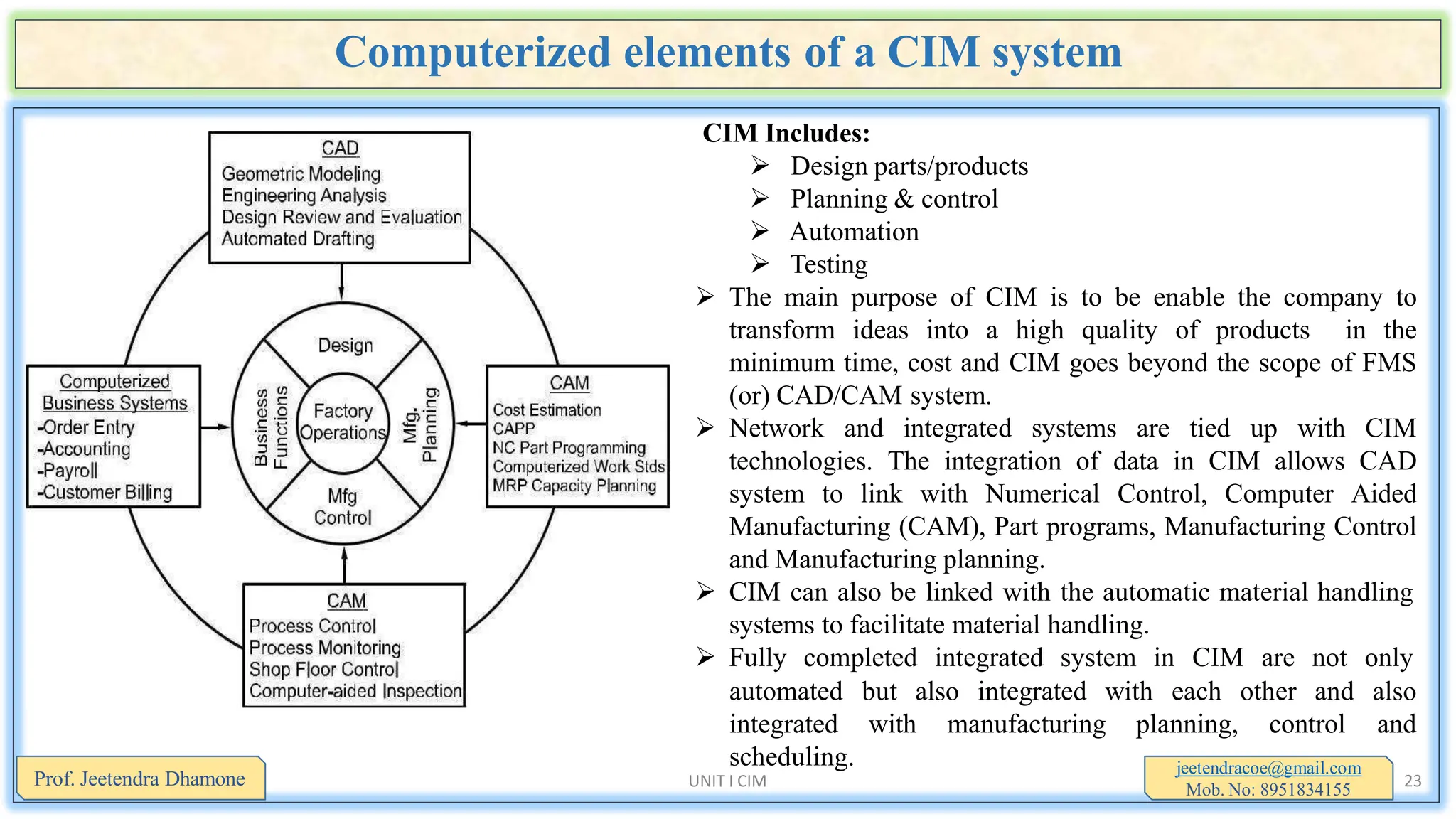

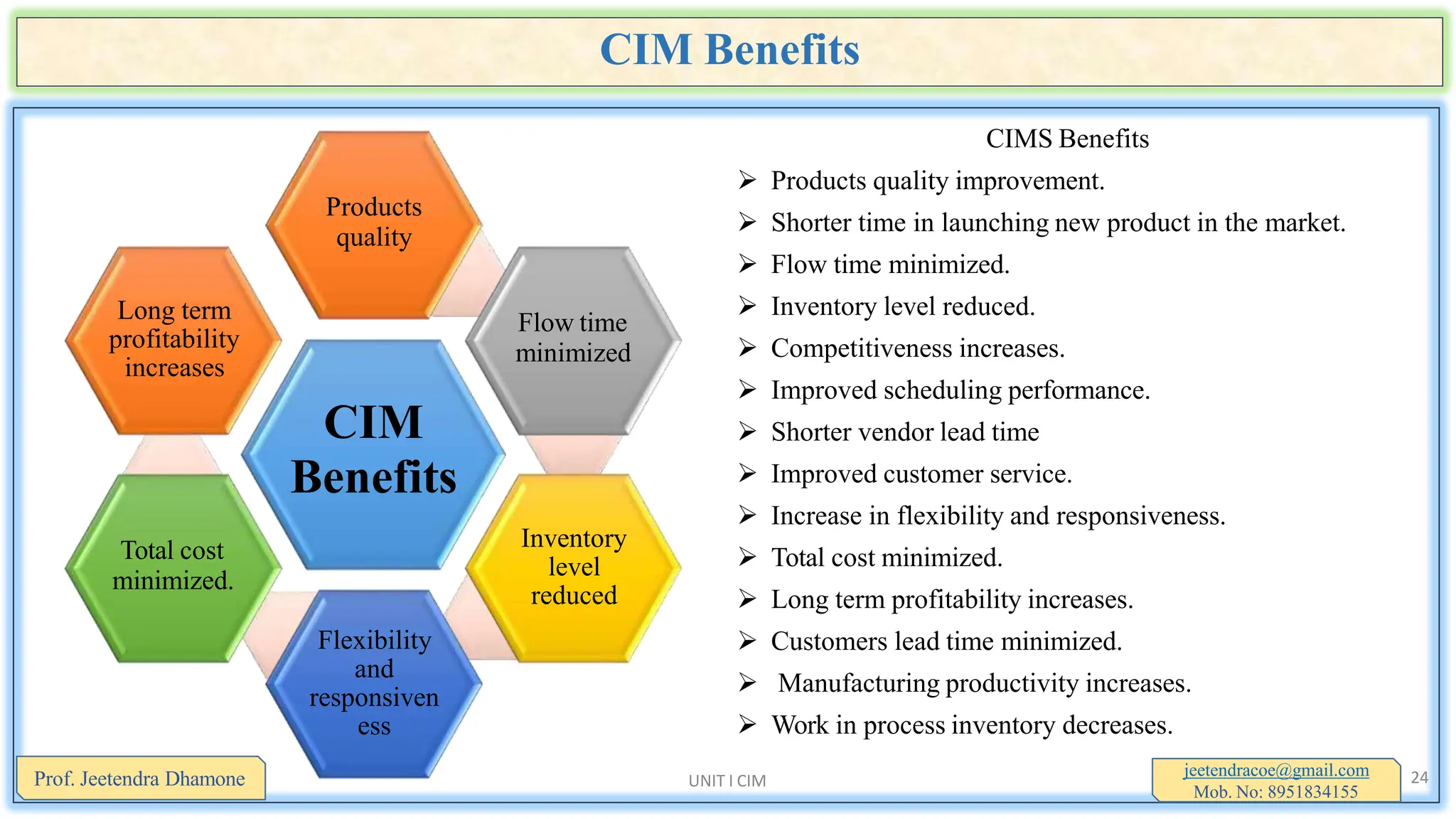

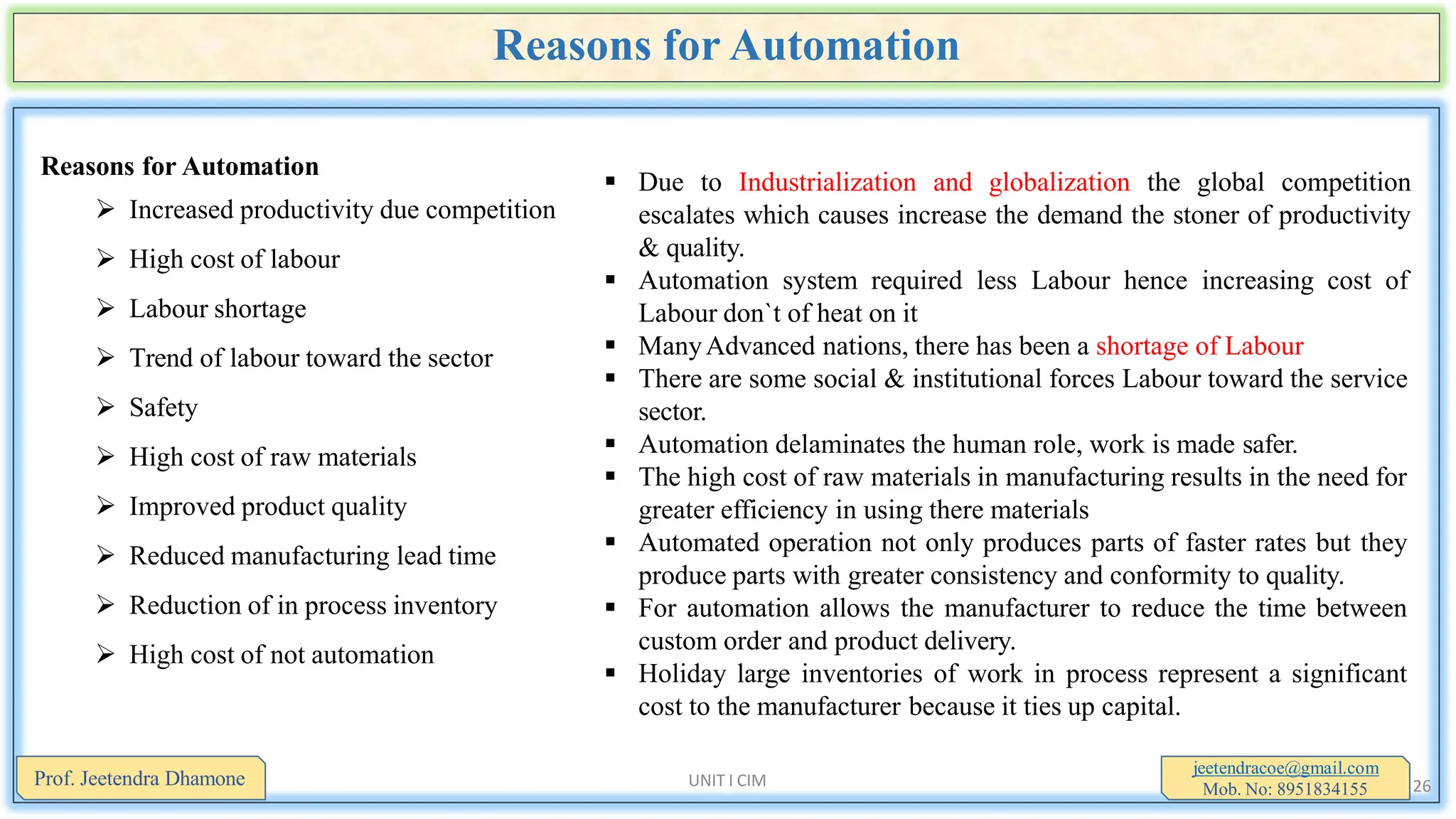

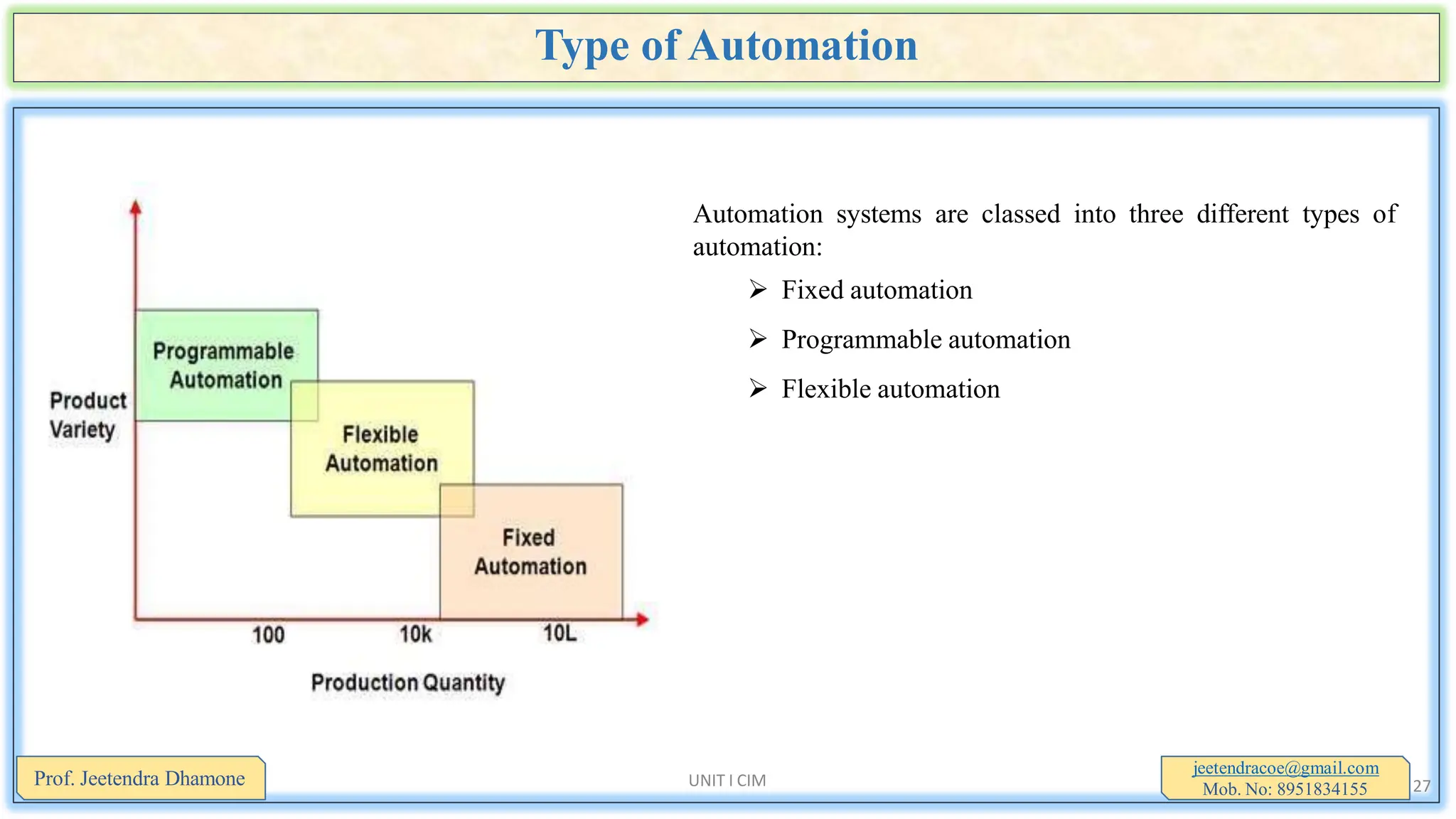

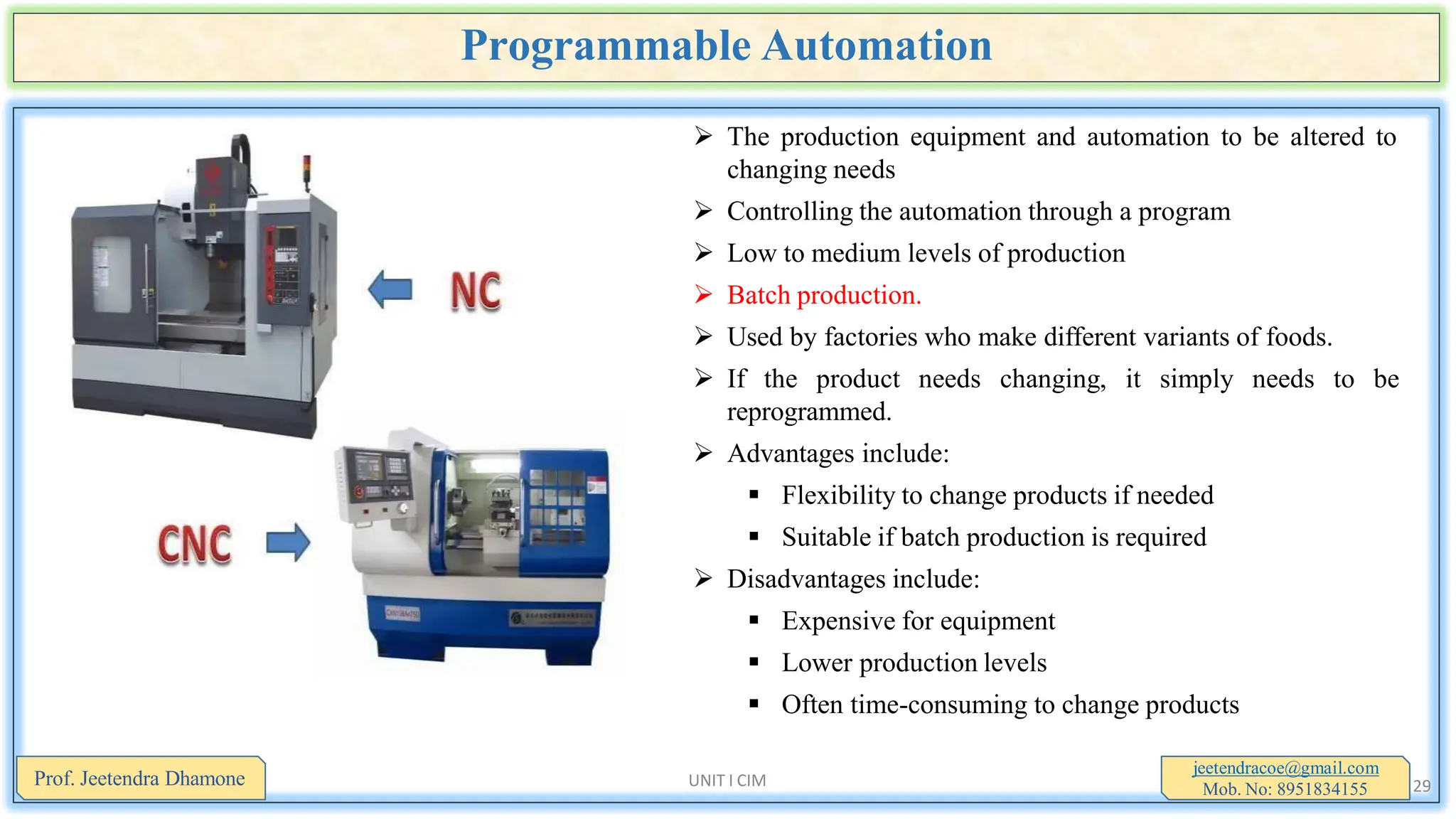

The document discusses Computer Integrated Manufacturing (CIM), detailing its necessity for modern manufacturing, including increased efficiency, accuracy, and competitiveness. It covers the evolution of CIM, components, software, and hardware involved in automated manufacturing processes, along with advantages such as improved data management and quality control. Additionally, it explores various types of automation systems and their roles in enhancing productivity and reducing operational costs.