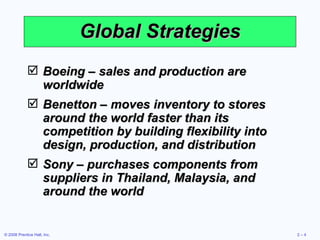

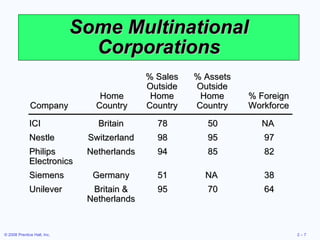

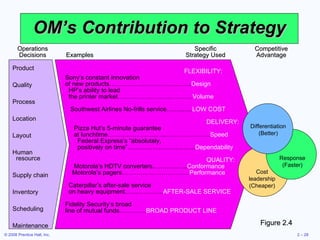

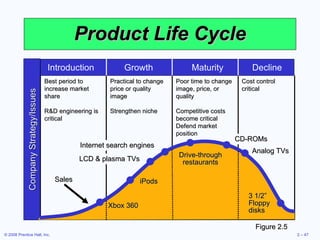

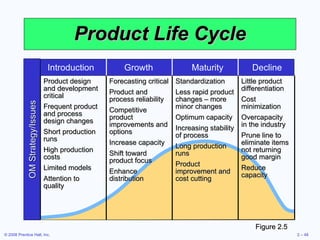

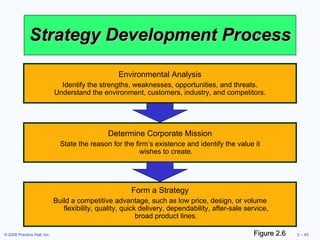

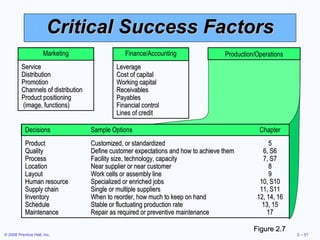

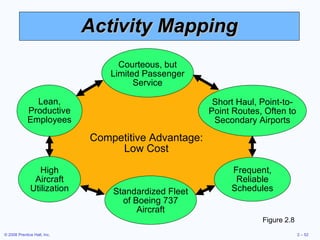

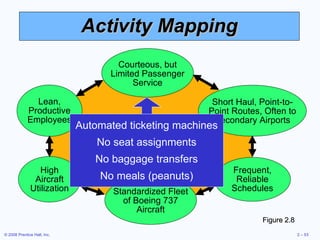

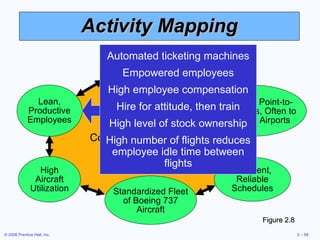

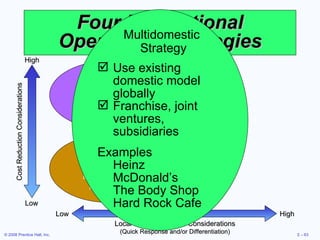

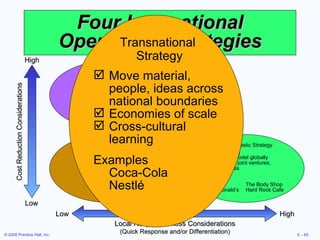

This document discusses operations management strategies in a global environment. It begins by outlining learning objectives related to defining mission/strategy and identifying strategic approaches. It then provides examples of multinational corporations and their foreign operations. Several global strategies are discussed, including standardization, localization, and examples of companies using each approach. Factors influencing globalization decisions are also summarized.