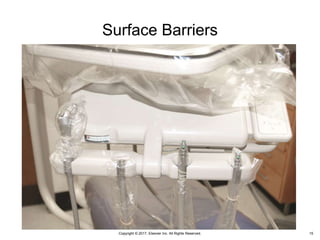

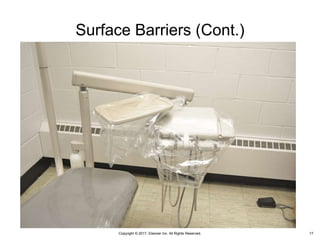

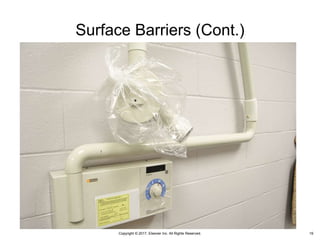

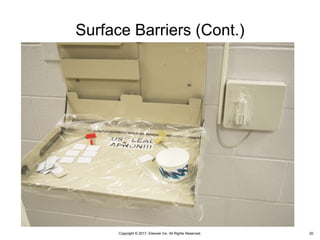

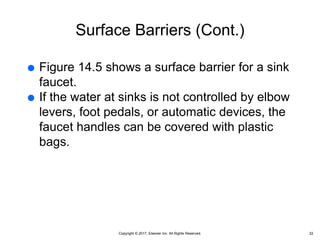

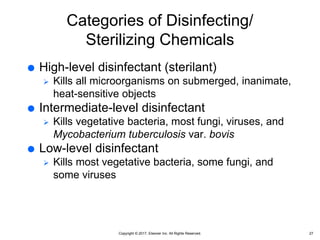

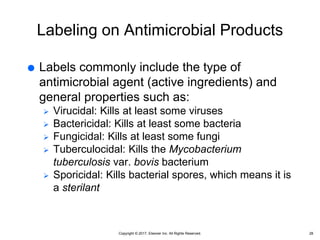

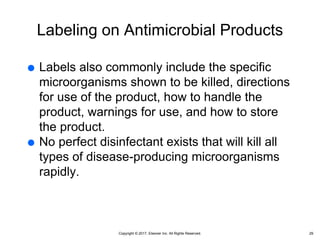

This document discusses surface and equipment asepsis in a dental office. It covers different types of environmental surfaces, approaches to surface asepsis including using surface barriers and precleaning/disinfecting surfaces. It describes how to properly use surface barriers to cover operatory surfaces. It also discusses characteristics of different types of disinfectants, including categories based on their microbial killing ability. The document provides details on labeling and ingredients of common surface disinfectants used in dental offices.