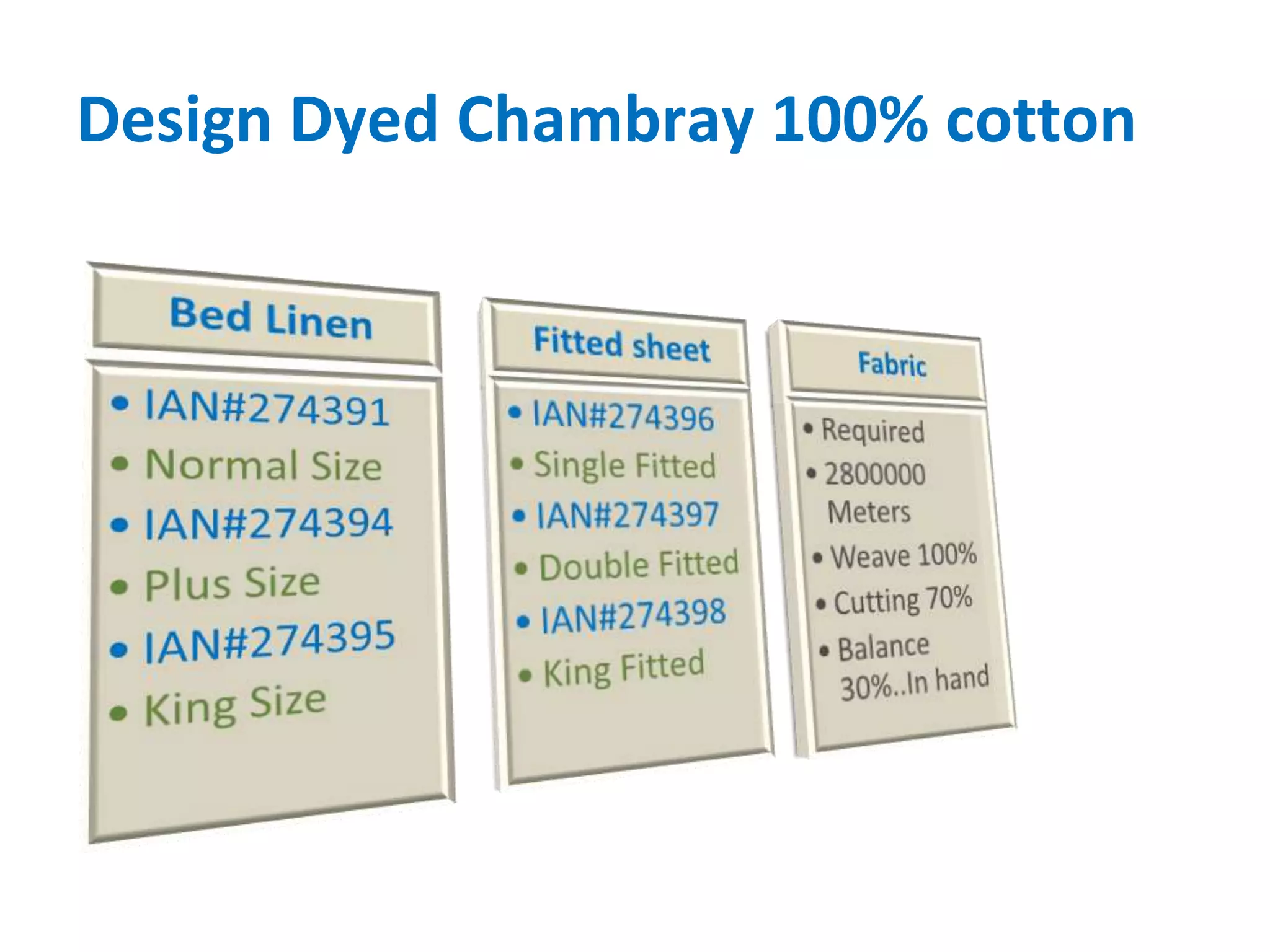

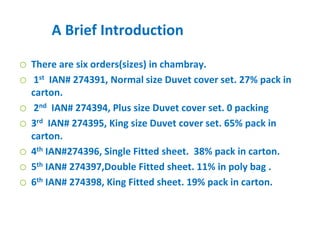

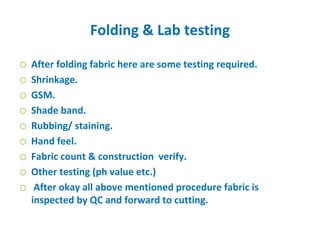

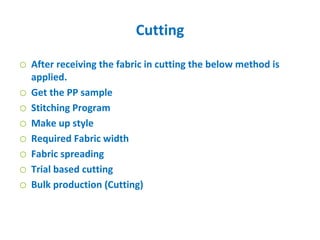

This document summarizes the process for designing and producing chambray duvet cover sets made of 100% cotton. It outlines 6 different order/size options and details the steps involved, including folding and testing fabric, cutting, stitching, checking, packing, inspection, and drop testing of finished cartons. The goal is to produce the duvet covers while meeting quality standards at each stage of processing.