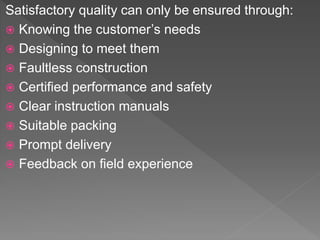

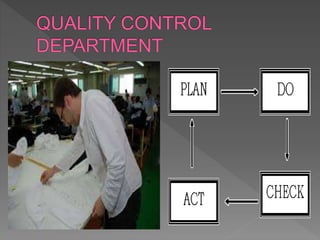

Quality in the garment industry is defined as the level of acceptance of goods and is essential from raw material sourcing to final product. Quality control involves a systematic process to ensure that products meet consumer specifications, addressing factors such as design, materials, and performance standards. Critical checks on materials like zippers and buttons—including their dimensions, durability, and appearance—are vital to maintaining the overall quality of garments.