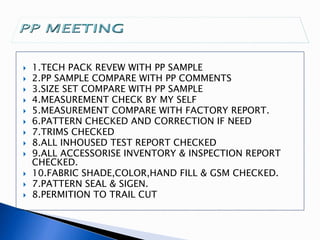

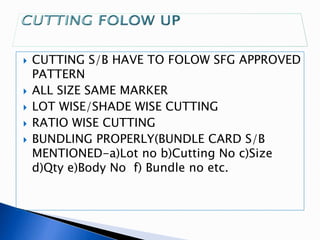

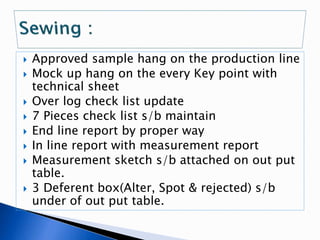

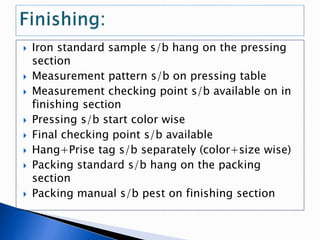

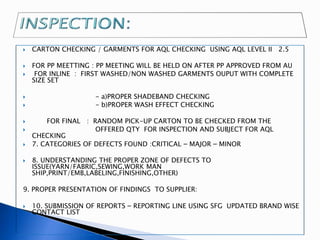

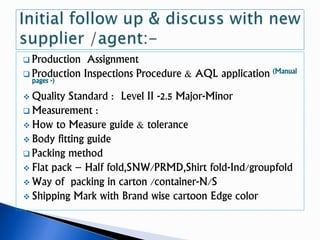

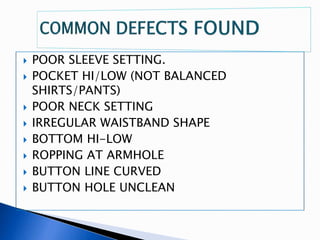

This document outlines quality control procedures for garment production including: 1) Comparing samples to technical specifications; 2) Checking measurements against reports; 3) Verifying patterns, trims, and materials. It also describes cutting, pressing, finishing, and packing standards such as bundling, marking, and hanging samples. Quality inspection includes AQL sampling for defects like poor sewing, sizing issues, and material problems. Findings are reported to suppliers according to the contact list.