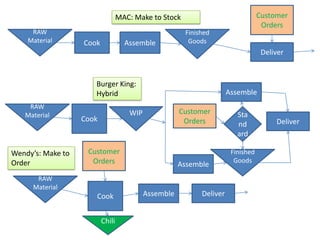

1. Lead time - The time from when a customer places an order to when it is delivered. Reducing lead time is important in make-to-order.

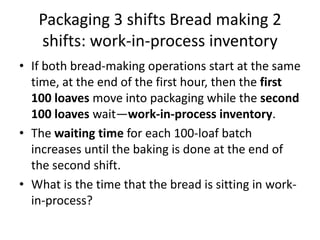

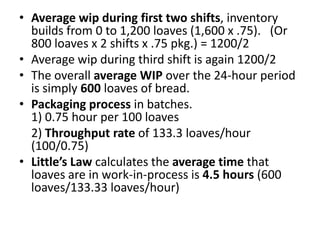

2. Work in progress (WIP) - The amount of unfinished orders at each stage of production. Lower WIP allows for more flexibility.

3. On-time delivery - The percentage of orders delivered by the promised date. Higher on-time rates increase customer satisfaction.

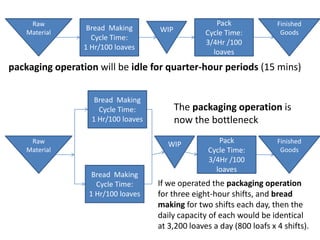

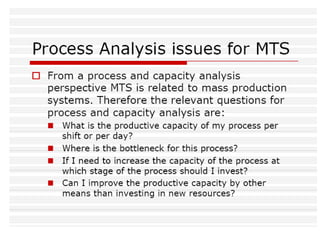

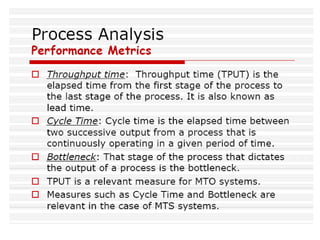

4. Process bottlenecks - Any steps that slow the overall flow of orders through production. Eliminating bottlenecks can speed up lead times.

5.