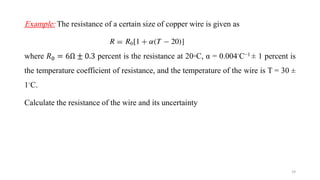

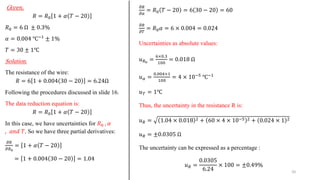

R = R0(1 + α(t - 20))

- The resistance (R) of a copper wire is calculated using a formula that relates it to the resistance at 20°C (R0), the coefficient of resistance (α), and the temperature (t).

- R0 is given as 6Ω with an uncertainty of ±0.3%.

- To determine the uncertainty in R, the uncertainties in R0, α, and t must be determined and propagated through the equation using partial derivatives.

- The overall uncertainty in R combines the individual uncertainties from each variable according to the propagation of uncertainty formula.