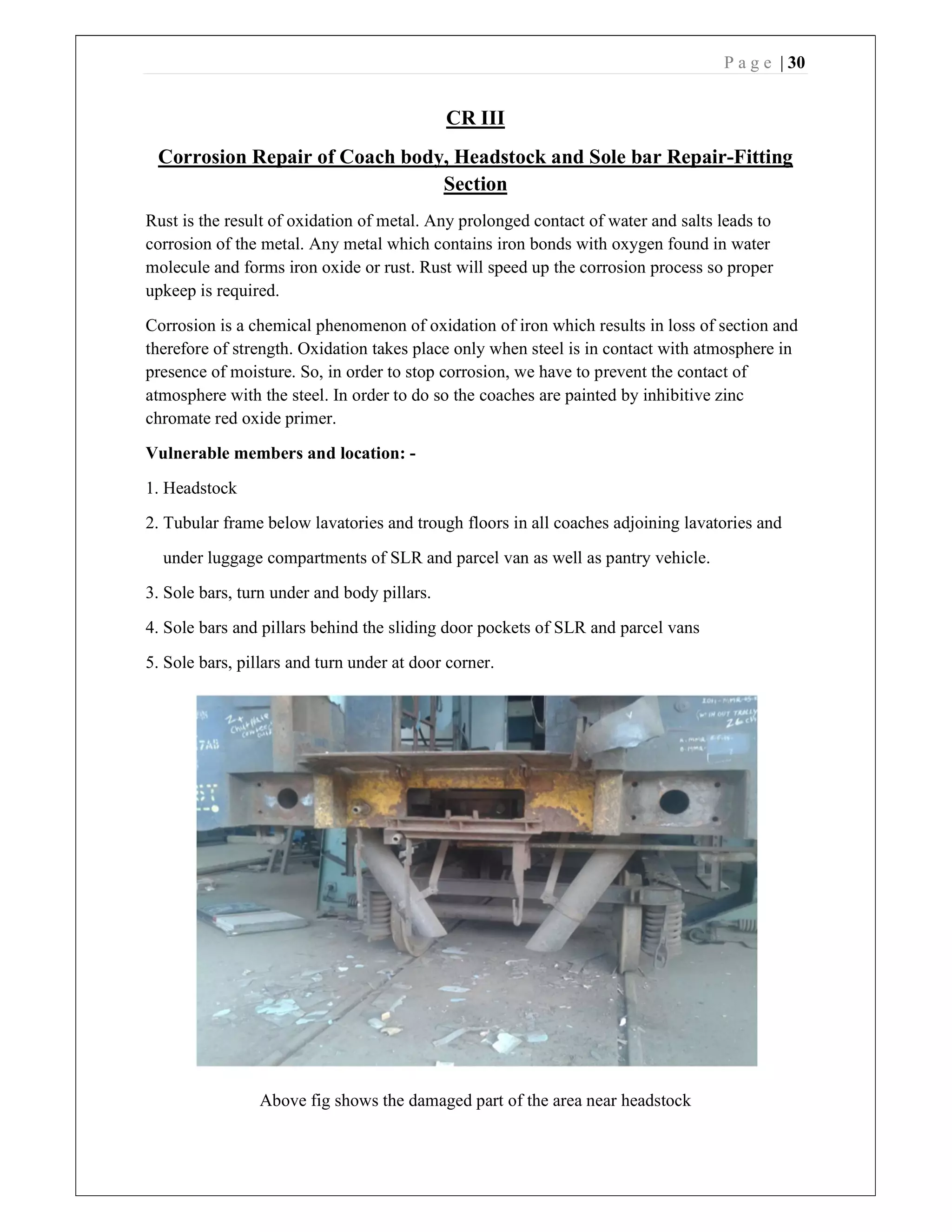

The document summarizes Chirag Jain's 15-day summer training at the Western Railway Carriage Repair Workshop in Mumbai. It includes an acknowledgement, declaration, preface, and schedule of shops visited each day including lifting and maintenance of ICF and FIAT bogies, suspension springs and shock absorbers, air brake systems, wheels and axles, and final inspection. Key activities of the workshop included periodic overhauling of 1500 passenger coaches per year. Maintenance processes for bogies, air brakes, and other components are described. Safety precautions and defects to check for during maintenance are also outlined.