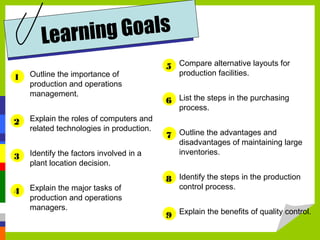

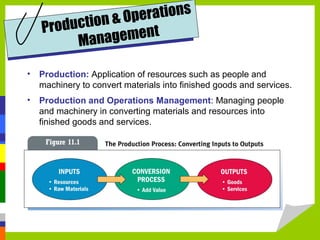

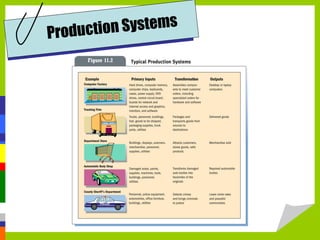

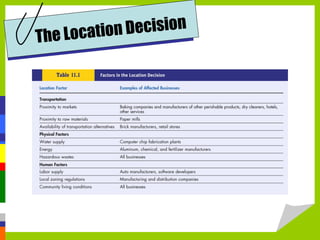

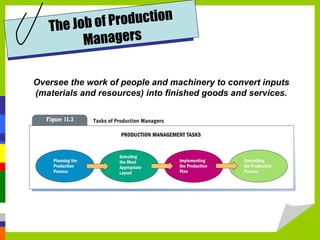

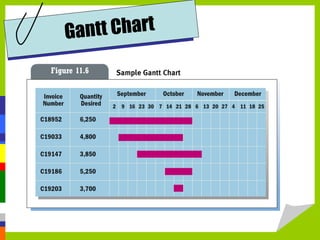

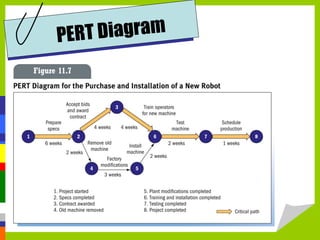

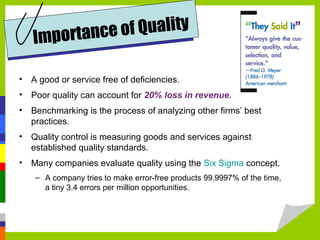

This document outlines key concepts in production and operations management. It discusses the importance of effective production, including lower costs, higher quality, and responsiveness to customers. Mass, flexible, and customer-driven production systems are compared. The roles of technology in manufacturing are also examined. Other major topics covered include plant location decisions, production planning and control, inventory management, quality control, and ISO standards.