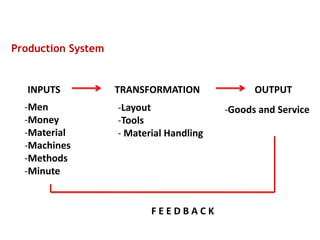

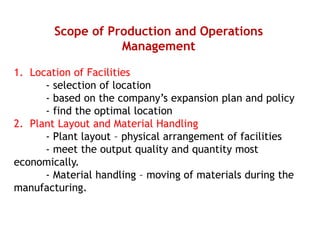

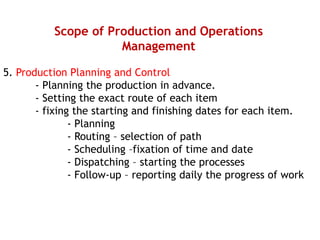

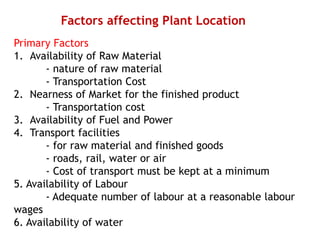

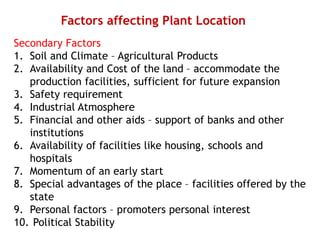

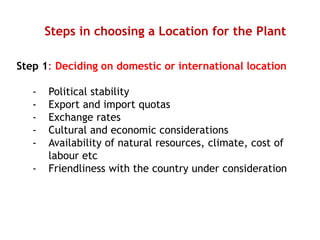

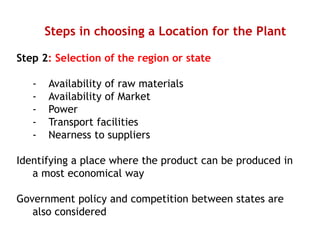

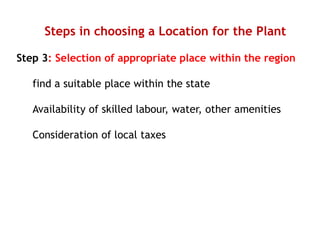

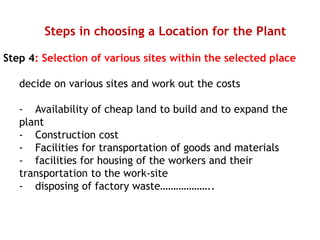

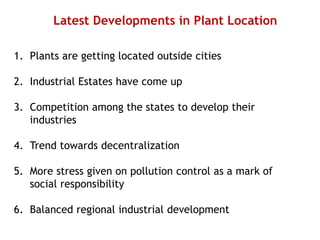

Production and operations management deals with the conversion of inputs into finished goods and services. It involves planning, organizing and controlling a firm's operations such as procurement, manufacturing and distribution. The key objectives are to maximize output, ensure quality and minimize costs. Recent trends include globalization, flexibility, reducing time to market and increased use of technology like CAD, CAM and supply chain management. Plant location is important and is influenced by factors like availability of raw materials, markets, labor, transportation and utilities.