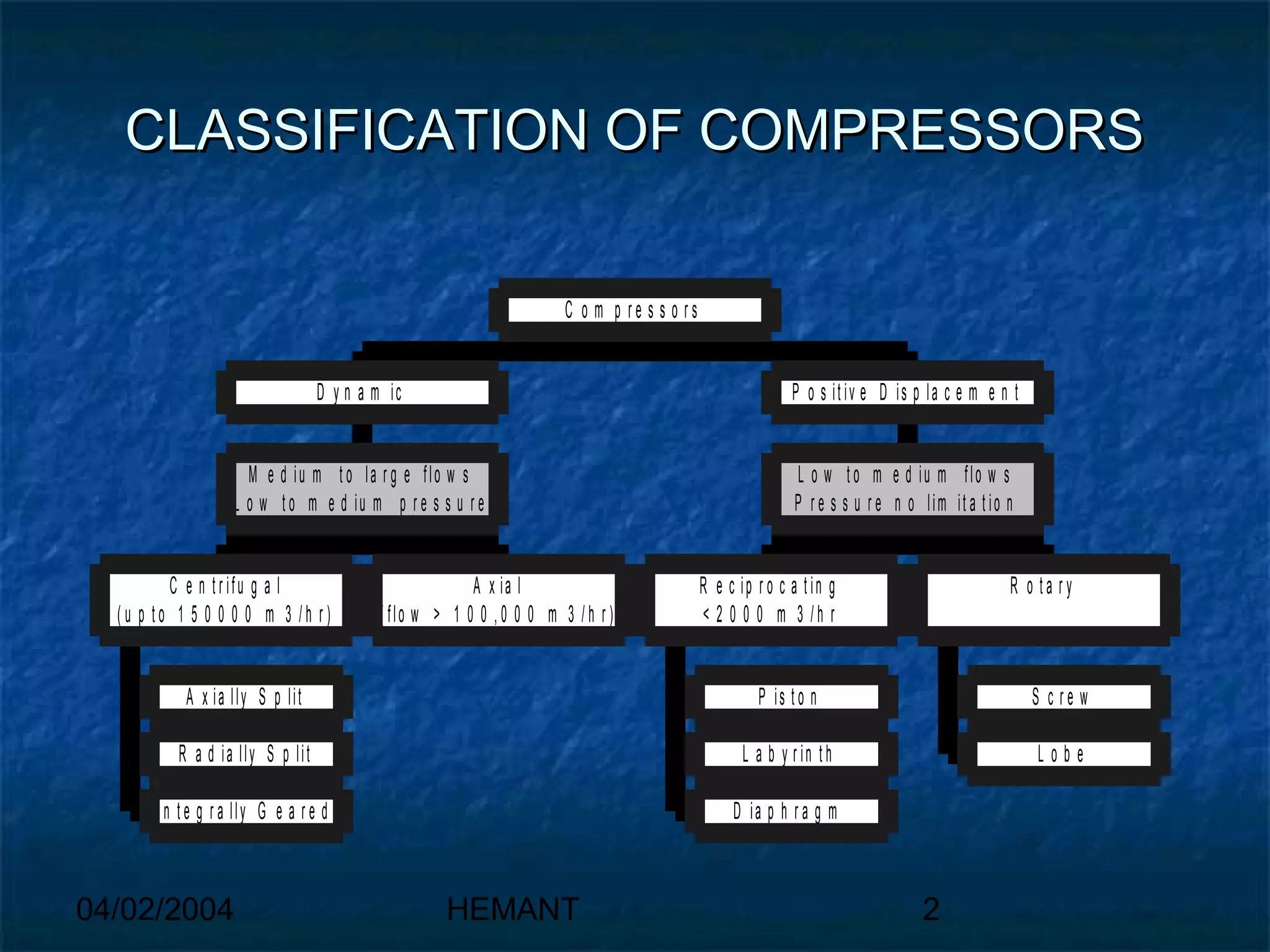

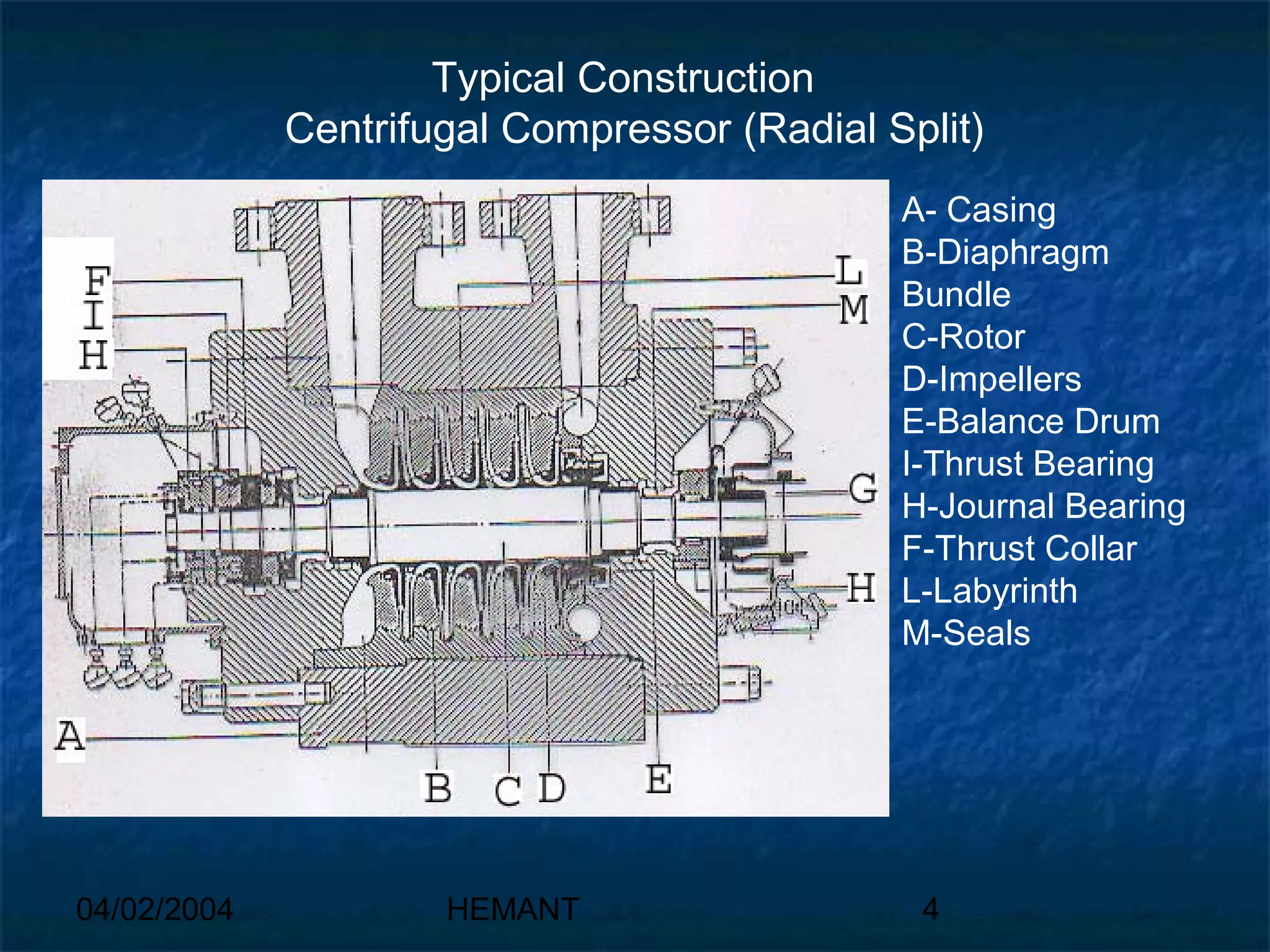

This document discusses various types of compressors used in industrial processes. It describes centrifugal compressors, which are commonly used for medium to large gas flows at low to medium pressures. Typical components of a centrifugal compressor include impellers, casings, rotors, and bearings. The document also discusses factors that affect compressor performance such as inlet pressure, temperature, and molecular weight of the gas. Methods of capacity control and anti-surge control are outlined.