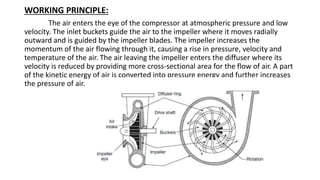

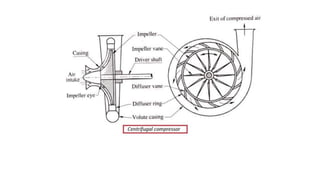

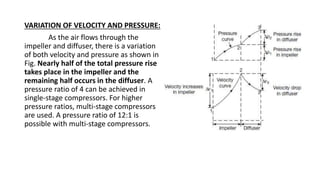

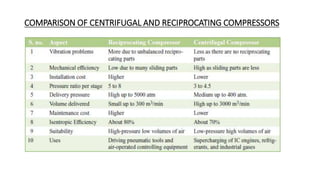

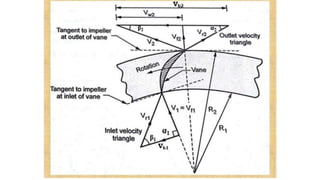

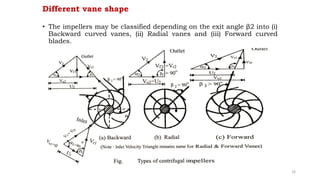

Rotary compressors use rotating blades to compress air. Centrifugal compressors use centrifugal force to continuously increase air pressure as it flows through an impeller and diffuser. Axial compressors increase pressure through rotating blades that accelerate air along the axis of rotation. Centrifugal compressors can achieve higher flow rates but lower pressure ratios than axial compressors. Both rotary compressor types operate at higher speeds and can supply more air than reciprocating compressors.