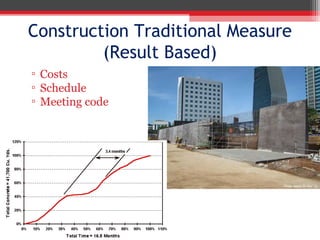

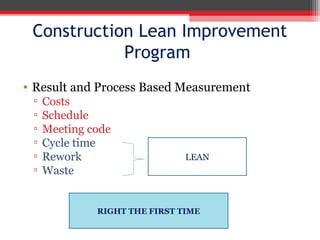

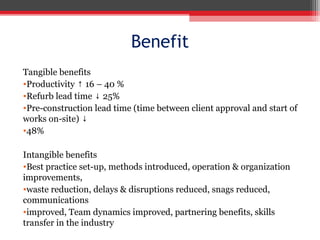

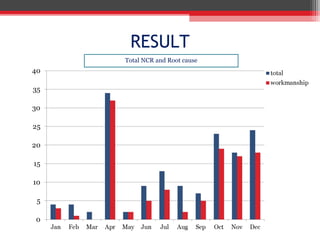

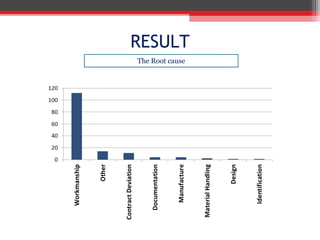

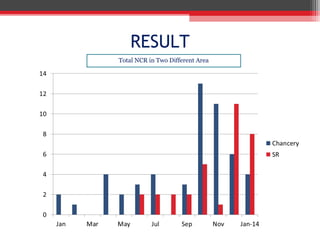

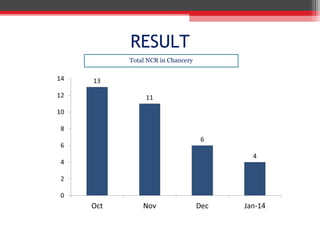

The document discusses rework reduction through the use of a Construction Lean Improvement Program (CLIP) on a case study of the New Australian Embassy in Jakarta construction project. It finds that implementing CLIP, including strategies like 5S, first inspector systems, and performance monitoring, led to a 57% reduction in non-conformance reports, saving $20,000. CLIP aims to eliminate waste and smooth workflow through lean thinking principles. The case study suggests expanding CLIP to other construction areas in the project to further reduce rework through continual training and quality monitoring processes.