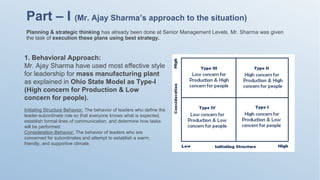

The case study analyzes the management of an underperforming team at a manufacturing plant, focusing on Ajay Sharma's strategic approach to improve productivity through group formation and leadership. Sharma identifies Chander Pal, an effective supervisor, as a leader to promote communication and address production issues, emphasizing total quality management and recognition as tools for motivation. The study outlines the roles of leadership and the necessity of monitoring and supporting workers to regain production targets that were previously missed.