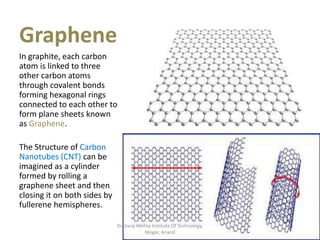

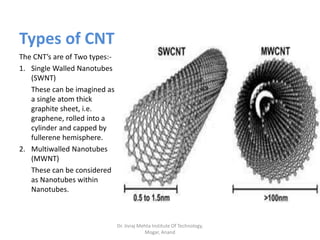

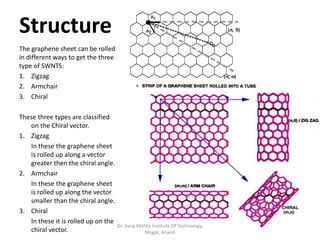

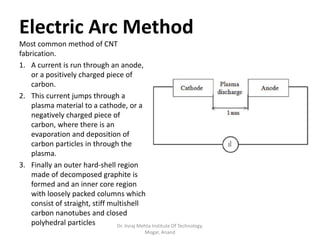

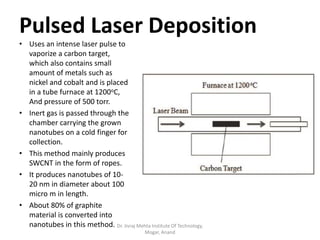

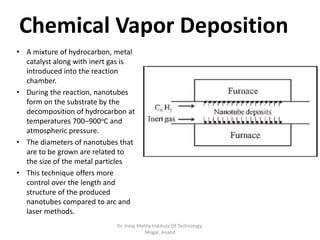

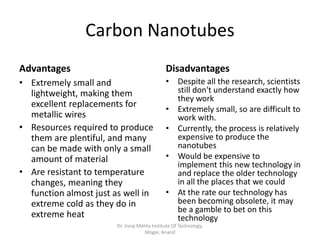

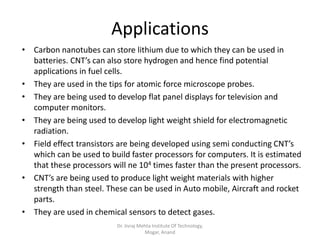

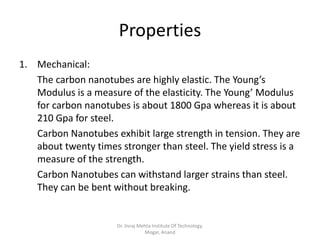

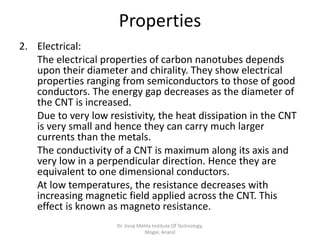

The document discusses carbon nanotubes (CNTs), detailing their structure, types (single-walled and multi-walled), and fabrication methods including electric arc, pulsed laser deposition, and chemical vapor deposition. It highlights the advantages of CNTs such as lightweight, high strength, and resilience to temperature changes, alongside challenges like production costs and complexity. Applications of CNTs are also explored, including their use in batteries, sensors, and advanced materials for various industries.