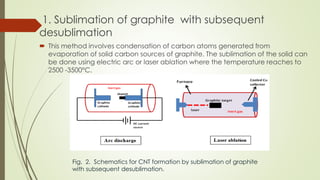

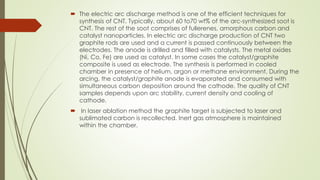

Carbon nanotubes and their applications are discussed. There are several allotropes of carbon including diamond, graphite, buckminsterfullerene (C60), and single-walled carbon nanotubes. Carbon nanotubes are cylindrical forms of carbon that can be single-walled or multi-walled. They are composed of hexagonal networks of carbon atoms and have remarkable mechanical, thermal, and electrical properties. Common synthesis methods for carbon nanotubes include arc discharge, laser ablation, and chemical vapor deposition using metal catalysts.

![CARBON

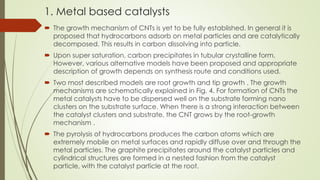

group- 14

period-2

Carbon is the 15th most abundant element in the Earth's crust, and

the fourth most abundant element in the universe by

mass after hydrogen, helium, and oxygen.

It is reactive non metal.

Electron configuration [He] 2s2 2p2

Electrons per shell 2,4 .

tetravalent—making four electrons available to

form covalent chemical bonds

Three isotopes occur naturally, 12C and 13C being stable, while 14C is

a radionuclide, decaying with a half-life of about 5,730 years.](https://image.slidesharecdn.com/copyofcarbonnanotubesyogesh-190206162121/85/carbon-nanotubes-2-320.jpg)

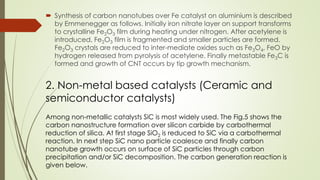

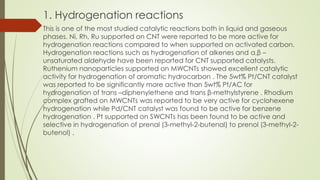

![2. Reaction involving CO/H2

CNTs have been investigated for Fischer –Tropsch reactions, methanol and

higher alcohol synthesis and hydroformylation reactions. Copper promoted

Fe/MWCNT catalyst are active for Fischer-Tropsch synthesis with olefins . Co-

Re/Al2O3 deposited on MWCNT by dip coating exhibited an enhancement

in Fischer-Tropsch activity than observed with a similar system without CNT

arrays. MWCNTs also have been used as promoter for Cu-ZnO-

Al2O3 catalysts for methanol synthesis using H2/CO/CO2 The complex

[HRh(CO)(PPh3)3] has been grafted onto MCWNTs and used for

hydroformylation of propene. Higher conversion and higher regioselectivity

toward n-butaldehyde have been reported for CNT supported catalysts

compared to that activated carbon or carbon molecular sieve supported

catalysts.](https://image.slidesharecdn.com/copyofcarbonnanotubesyogesh-190206162121/85/carbon-nanotubes-35-320.jpg)

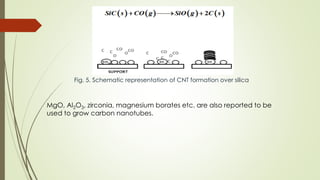

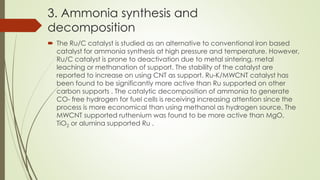

![4. Polymerization

The CNTs have excellent thermal and electrical conductivities and reported to

be used as fillers in polymer based advanced composites. However due to poor

solubility of CNTs, homogeneous dispersion is difficult task. The polymer

functionalized CNTs are prepared following three approaches:

A non-covalent functionalization method in which polymers are produced

by ring opening metathesis polymerization. The coating of hyper branched

polymers on MWCNTs has been obtained via cationic ring opening

polymerization of 3-ethyl-3-(hydroxymethyl)oxetane with a BF3 .Et2O catalyst

A covalent functionalization performed by, first grafting polymerization

initiators onto the tubes through covalent bond and then exposing these CNT

based macro-initiators to the monomer. The polymer is obtained by atom

transfer radical polymerization. The polyethylene-MWCNT composite has

been produced using catalyst grafting procedure by polymerization of

ethylene on [ZrCl2Cp2] MAO/MWCNT where Cp = C5H5 and MAO =

methylaluminoxane .](https://image.slidesharecdn.com/copyofcarbonnanotubesyogesh-190206162121/85/carbon-nanotubes-37-320.jpg)