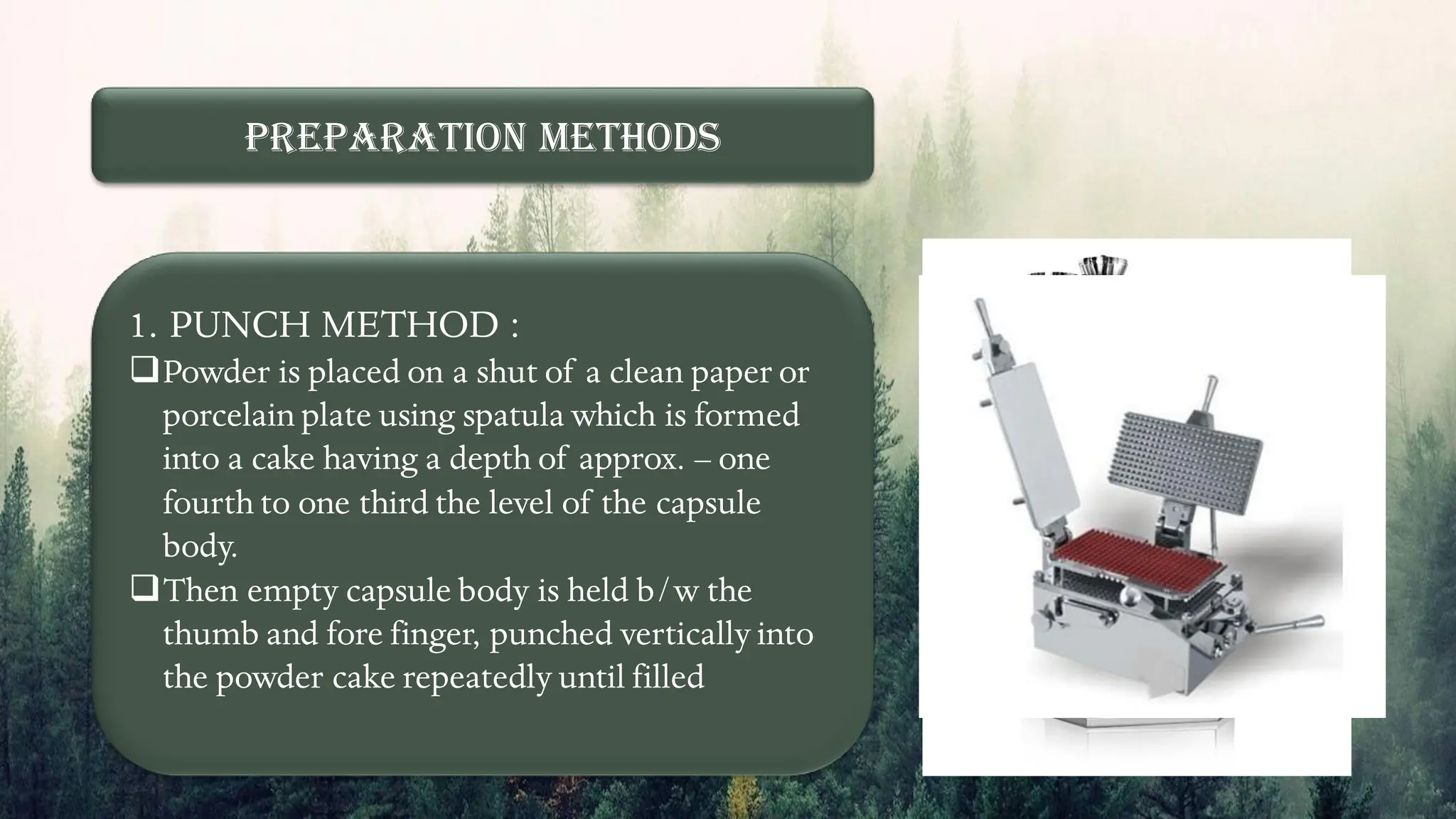

The document provides an overview of hard and soft gelatin capsules, including their definitions, advantages, disadvantages, and manufacturing processes. It details the steps involved in producing empty gelatin capsules, filling them with solid medicaments, and the components needed for soft gel formulations. Additionally, it describes the composition and methods used to manufacture soft gel capsules, emphasizing the importance of gelatin and various additives.

![SOFT GELATIN CAPSULE

1. capsule shell water :

• NMT 45% w/w the ratio by weight of water to

dry gelatin can vary from 0.7% to 1.3[water] to

1.0 [dry gelatin] depending on the viscosity of

the gelatin being used.

2. Plasticizer :

• Used to make the soft gel shell elastic & pliable

• Ratio used is b/w 0.3 to 1.8 for soft to hard

shell on dry basis Ex :- glycerin, sorbitol.](https://image.slidesharecdn.com/capsule100939withyou-231124181658-3dc2516e/75/Capsule-manufacturing-of-capsule-Soft-gelatin-capsule-preparation-methods-Evaluation-of-capsule-package-and-storage-16-2048.jpg)