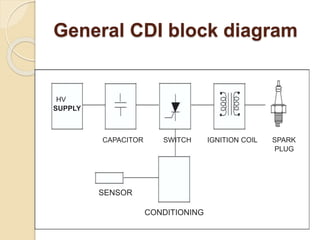

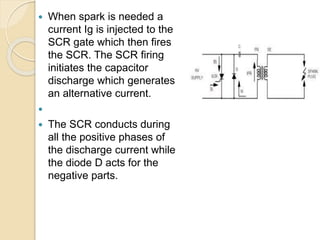

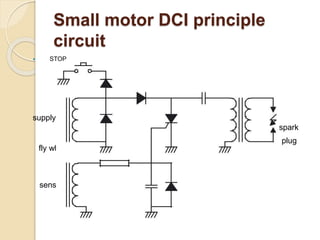

The document discusses capacitive discharge ignition (CDI) systems. CDI systems work by storing energy from a high voltage supply in a capacitor and then discharging the capacitor through an ignition coil and spark plug to generate a spark. There are two main CDI topologies - one uses an SCR to control discharge of the capacitor through the ignition coil primary, while the other uses both an SCR and free-wheeling diode. CDI systems offer advantages like fast voltage rise and insensitivity to resistance, making them suitable for small engines and improving cold starting. However, their short spark duration can limit reliability in some applications.