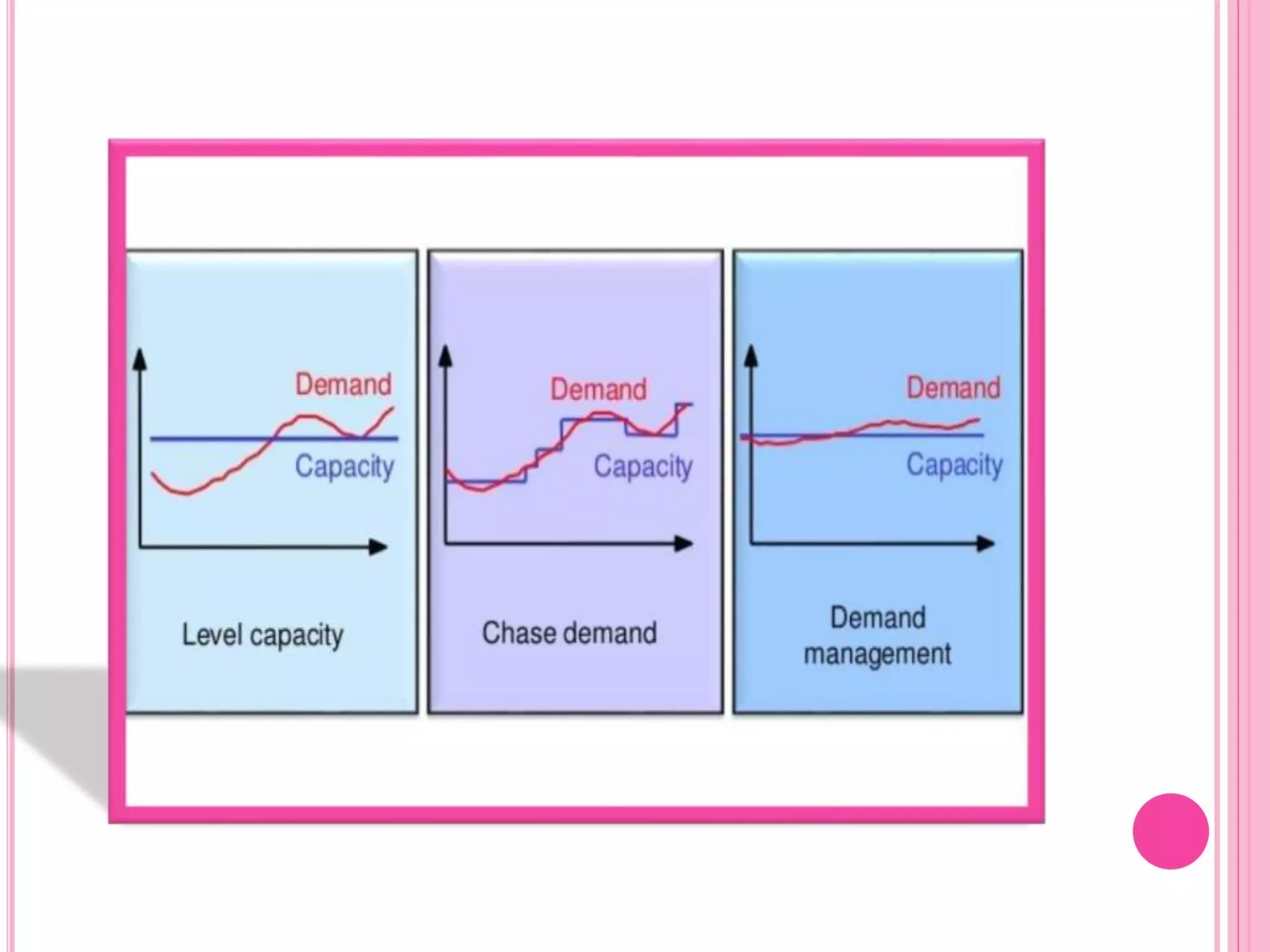

This document discusses capacity planning and identifies key aspects of evaluating capacity requirements and plans. It describes measuring customer demand through forecasts and measuring current organizational capacity levels. It then evaluates three approaches to capacity planning: level capacity which fixes capacity at a constant level; chase demand which adjusts capacity to match fluctuating demand; and demand management which attempts to adjust demand to meet available capacity through strategies like varying price, marketing efforts, or an appointment system.