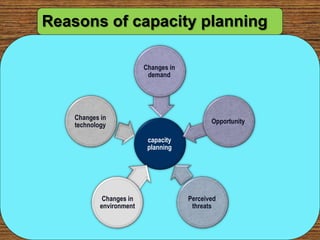

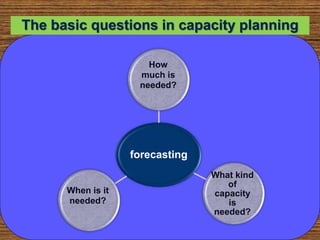

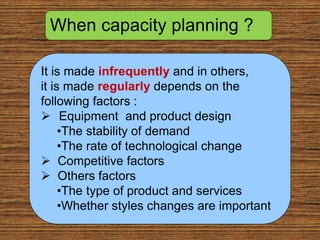

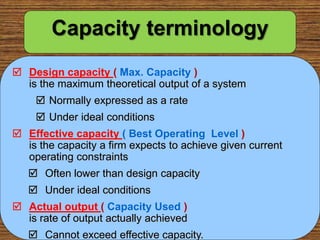

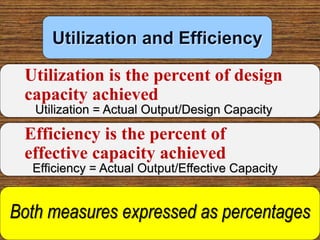

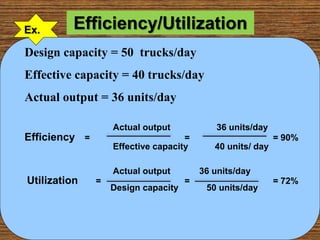

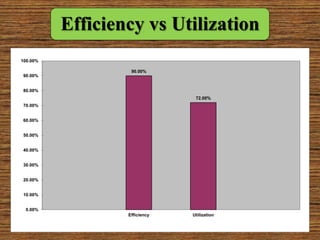

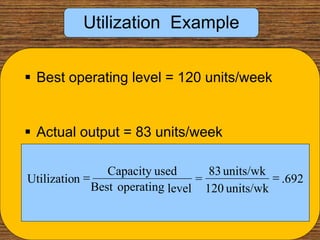

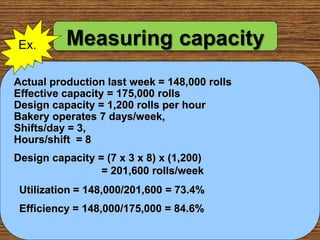

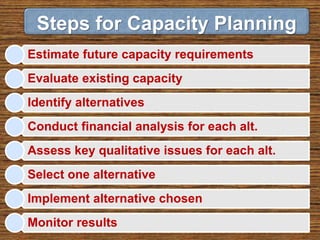

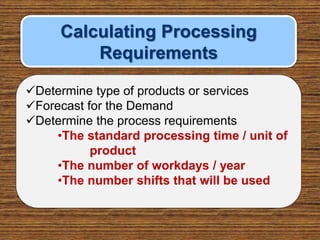

This document discusses capacity planning concepts. It defines capacity as the upper limit of load an operating unit can handle. Effective capacity is the best operating level given constraints, while actual output is the rate achieved. Capacity planning aims to match supply capabilities to predicted demand levels. It is done infrequently when equipment or demand is stable, and more regularly when they change rapidly. Key questions in capacity planning include how much, what kind, and when capacity is needed.