This document discusses various meshing techniques in ANSYS Workbench including:

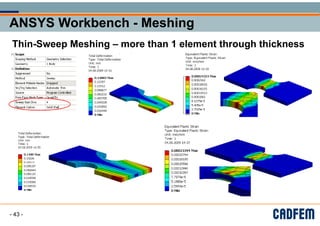

- Direct meshing which allows more control over the meshing order of multiple bodies compared to automated meshing.

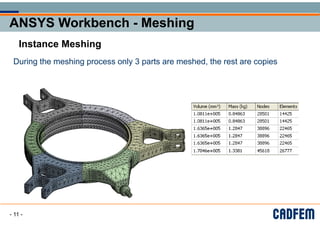

- Instance meshing which only meshes a single instance of identical parts to reduce meshing time.

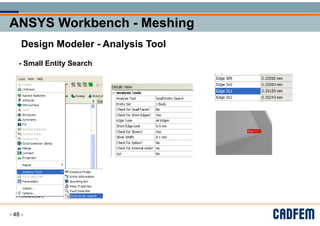

- Share topology which identifies matching faces and edges between connected parts to improve mesh quality at interfaces.

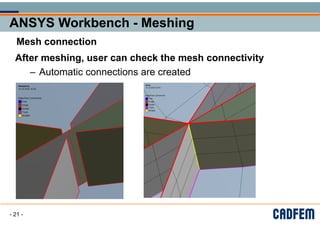

- Mesh connections which define the connectivity between meshes of different parts automatically during meshing.

- Advanced sizing functions which allow non-uniform mesh sizes to be defined across a model.