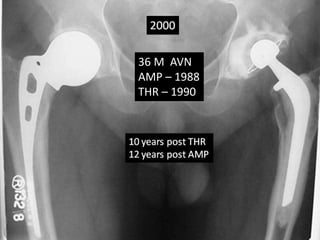

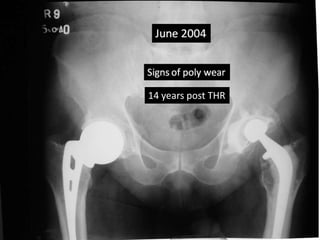

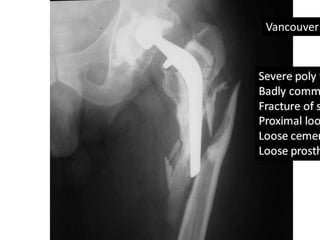

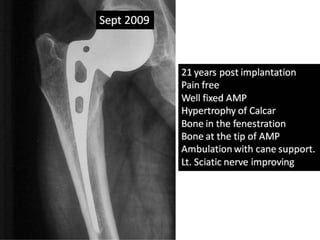

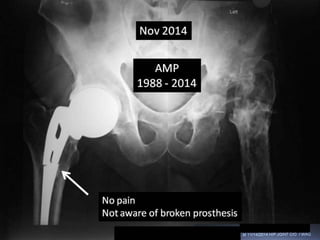

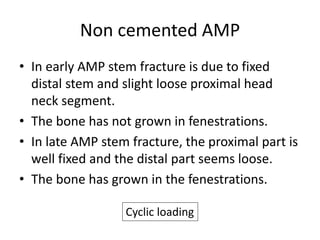

This case report describes a 36-year-old male who underwent an AMP for bilateral avascular necrosis of the hips in 1988. He later required a total hip replacement on the left side in 1990. In 2009, following a traffic accident, he suffered a Vancouver B3 peri-prosthetic fracture requiring revision surgery with a Mennen plate and Solution stem. In 2012, a crack was discovered in the original AMP stem, showing signs of metal fatigue after 24 years. The AMP stem had stood the test of time without causing pain.